Yeah I'll go the half size one I think it's 30lt ish should last a life time.yes, its the 13.2 gallon kegmentor. I figured 10-11 gallons max for me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show Us Your Gear!

- Thread starter Yooper

- Start date

- Joined

- Mar 30, 2021

- Messages

- 1

- Reaction score

- 8

- Points

- 3

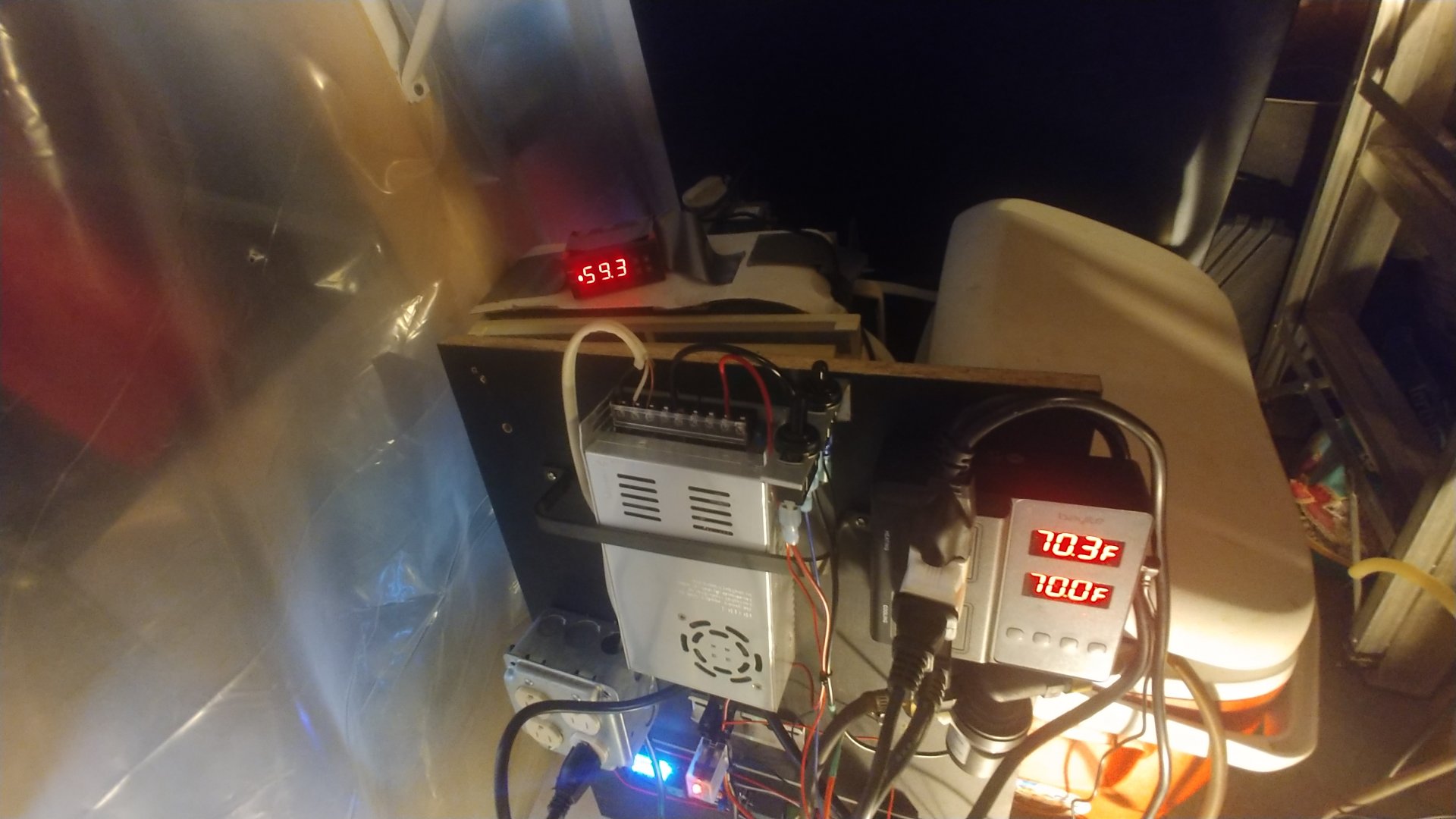

This is my brew cart I put together a few months ago. Full contained, mobile, 110V. Chiller for cold crashing.

Aww noice noice man that is some bling!This is my brew cart I put together a few months ago. Full contained, mobile, 110V. Chiller for cold crashing.View attachment 14977

That's a glycol unit there under the bench ?

- Joined

- Feb 25, 2017

- Messages

- 3

- Reaction score

- 12

- Points

- 3

I just finished building my 3v e-herms set up. I previously brewed on propane with two igloo colors and a Blichmann 15g kettle. Spent the last month finishing the build of my panel, cords, and probe sensors. First brew day on the system will be this weekend. Can’t wait!

here's one of the kegmentor in action-11gal batch, connected to an icemaster on a rolling cart. also had 5.5gal stout at the same time.

Last edited:

- Joined

- Sep 1, 2020

- Messages

- 1

- Reaction score

- 5

- Points

- 3

- Joined

- Mar 31, 2021

- Messages

- 4,307

- Reaction score

- 6,396

- Points

- 113

Been working on this for 5 years off and on. changed a few things like adding a RIMS heater inline to raise temp more quickly during mashing and a mesh basket which complettely eliminated stuck sparges.

The whole unit is based on BIAB with a HERMS. the boiling pot and the mash tun are the same kettle(left). has 4500 watts of heating elements. The other pot is for the HERMS. use it for mashing and chilling wort after boil. HERMS pot has a 1500 heating element in it for mashing.

The Pump is an old March Pump.

The controller is a custom device made from a Splatt Controls MMi202 microcontroller. I wrote the firmware for the controller just for brewing purposes.

If you are interested, you can visit my website blog and view all the work put into it. just click on "brewery" link

http://www.minbarisplace.com/

The whole unit is based on BIAB with a HERMS. the boiling pot and the mash tun are the same kettle(left). has 4500 watts of heating elements. The other pot is for the HERMS. use it for mashing and chilling wort after boil. HERMS pot has a 1500 heating element in it for mashing.

The Pump is an old March Pump.

The controller is a custom device made from a Splatt Controls MMi202 microcontroller. I wrote the firmware for the controller just for brewing purposes.

If you are interested, you can visit my website blog and view all the work put into it. just click on "brewery" link

http://www.minbarisplace.com/

Making great use of the bbqStill building out indoor electric hood, control panel built. Enjoying the outdoor fireplace for now.

You like your plate chiller I've had options on one of them but have herd mixed reviews...here's one of the kegmentor in action-11gal batch, connected to an icemaster on a rolling cart. also had 5.5gal stout at the same time. View attachment 14980

- Joined

- Mar 14, 2018

- Messages

- 11,068

- Reaction score

- 20,795

- Points

- 113

This is my brew cart I put together a few months ago. Full contained, mobile, 110V. Chiller for cold crashing.View attachment 14977

I just finished building my 3v e-herms set up. I previously brewed on propane with two igloo colors and a Blichmann 15g kettle. Spent the last month finishing the build of my panel, cords, and probe sensors. First brew day on the system will be this weekend. Can’t wait!

View attachment 14979

here's one of the kegmentor in action-11gal batch, connected to an icemaster on a rolling cart. also had 5.5gal stout at the same time. View attachment 14980

Wow!Still building out indoor electric hood, control panel built. Enjoying the outdoor fireplace for now.

Some cool looking setups, thanks to you all, or should I say y'all, for sharing!

Love it. From Duda diesel. Compact. Can get wort in 70s single pass with a valve in the outlet. -That is with tap water. 80deg in the summer. i might need to run cooling water through some ice to get wort below 80 in the summer.You like your plate chiller I've had options on one of them but have herd mixed reviews...

Last edited:

- Joined

- Jul 19, 2019

- Messages

- 2,459

- Reaction score

- 6,491

- Points

- 113

Nice setup... More importantly, I see a Raider's patch...Go Raiders!!!!!This is my brew cart I put together a few months ago. Full contained, mobile, 110V. Chiller for cold crashing.View attachment 14977

Been working on this for 5 years off and on. changed a few things like adding a RIMS heater inline to raise temp more quickly during mashing and a mesh basket which complettely eliminated stuck sparges.

The whole unit is based on BIAB with a HERMS. the boiling pot and the mash tun are the same kettle(left). has 4500 watts of heating elements. The other pot is for the HERMS. use it for mashing and chilling wort after boil. HERMS pot has a 1500 heating element in it for mashing.

View attachment 14986

The Pump is an old March Pump.

View attachment 14987

The controller is a custom device made from a Splatt Controls MMi202 microcontroller. I wrote the firmware for the controller just for brewing purposes.

View attachment 14988

If you are interested, you can visit my website blog and view all the work put into it. just click on "brewery" link

http://www.minbarisplace.com/

Wow- that’s cool!

Nice, another indoor brewer.

- Joined

- Jan 7, 2018

- Messages

- 31

- Reaction score

- 35

- Points

- 18

- Joined

- Mar 31, 2021

- Messages

- 4,307

- Reaction score

- 6,396

- Points

- 113

View attachment 15016 View attachment 15017 My 50L 3v HERMS set up. Home made HERMS & Counterflow Chiller. I keg everything these days. There’s 4 x 25L FastFerment conicals in the wooden enclosure on the right, and two fridges under a bar with a twin tower tap behind the photographer.

4 fermentors, nice! I need to get a second one. Until I can get my homemade glycol chiller working the way I want it. Not going to bother

- Joined

- Mar 31, 2021

- Messages

- 4,307

- Reaction score

- 6,396

- Points

- 113

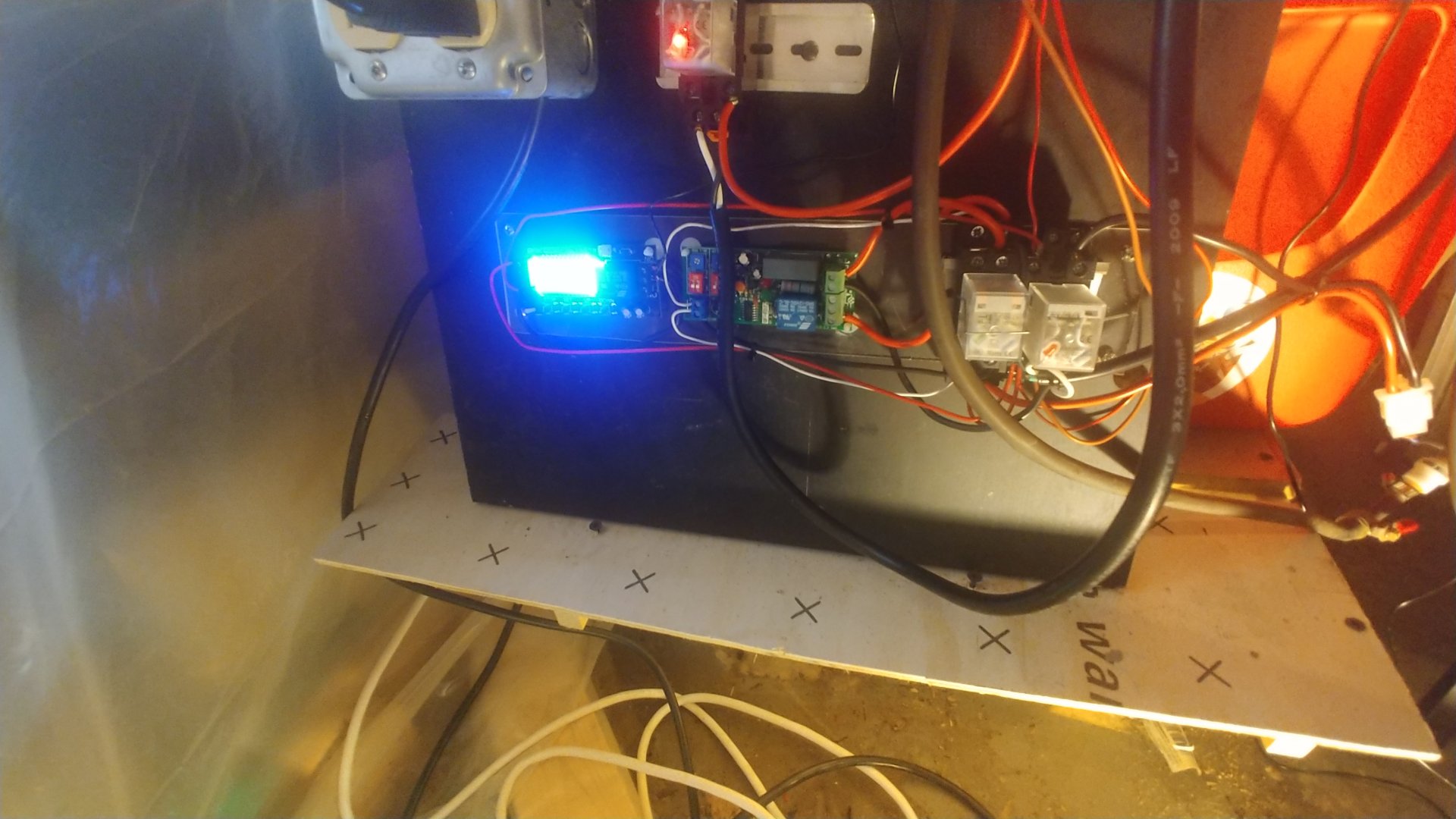

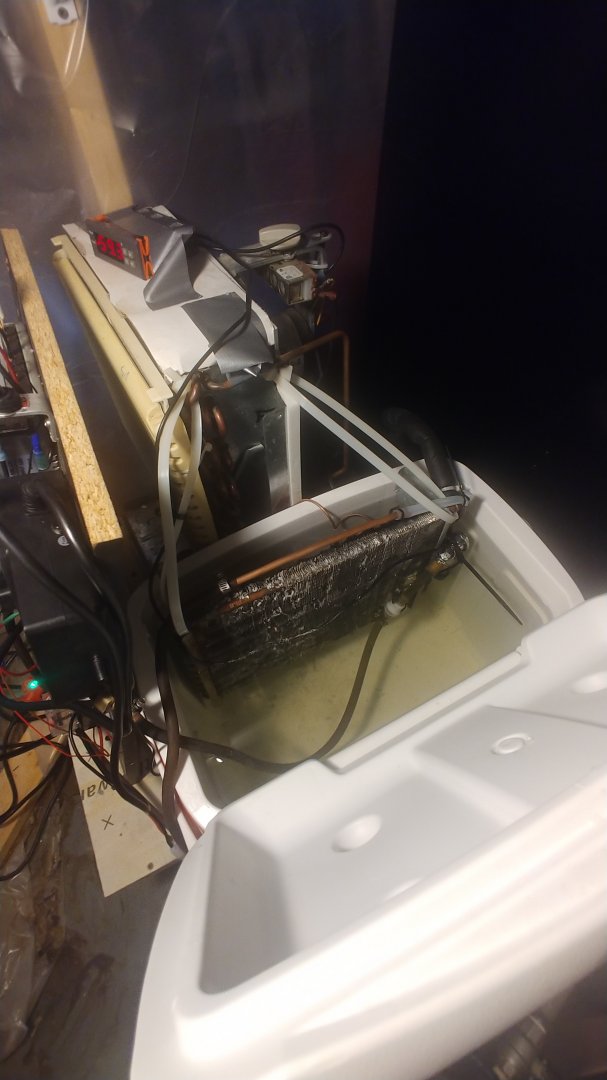

The key to any good beer system is controlling the temp during fermentation. To that end I have spent the last year or more in designing and implementing this temp control system. The first version used a small college fridge as the cooling source but it simply could not keep up. I had an old dehumidifier that I modified to chill a 35% glycol/water solution.

Put simply the system uses the chilled glycol solution through a chiller coil in the fermenter to cool the wort and the aquarium heater to warm it, depending on what the external conditions are. it can hold the wort at 34° F indefintely.

I added a thermowell to monitor temperatures as well as provide feedback for temp control system. Added a simple aquarium heater as well as a stainless chiller coil.

The purge valve was added to allow co2 to back fill the head space during hop or flavor additions. It also allows purging the headspace when dumping trub through the new bottom valve and catch cup.

view of the thermowell and chiller coil ports.

View of the chiller coil, heater and purge valve tube.

view of the bottom valve and catch cup. both items removable via 1.5" TC connectors. You can also view the sample port and purge valve. (right)

Put simply the system uses the chilled glycol solution through a chiller coil in the fermenter to cool the wort and the aquarium heater to warm it, depending on what the external conditions are. it can hold the wort at 34° F indefintely.

I added a thermowell to monitor temperatures as well as provide feedback for temp control system. Added a simple aquarium heater as well as a stainless chiller coil.

The purge valve was added to allow co2 to back fill the head space during hop or flavor additions. It also allows purging the headspace when dumping trub through the new bottom valve and catch cup.

view of the thermowell and chiller coil ports.

View of the chiller coil, heater and purge valve tube.

view of the bottom valve and catch cup. both items removable via 1.5" TC connectors. You can also view the sample port and purge valve. (right)