You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show Us Your Gear!

- Thread starter Yooper

- Start date

- Joined

- Nov 24, 2013

- Messages

- 191

- Reaction score

- 359

- Points

- 63

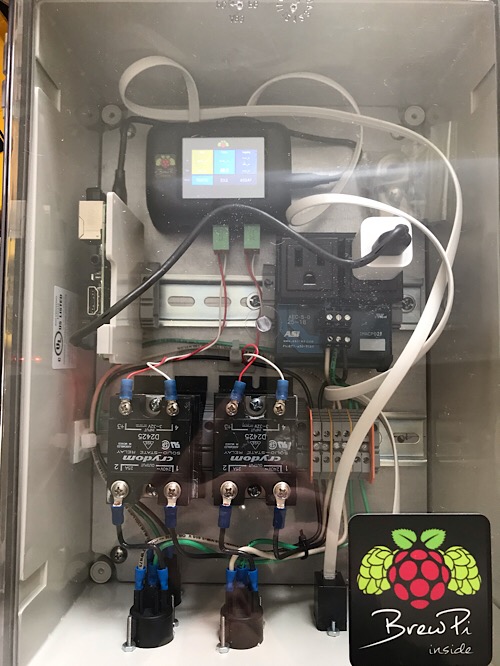

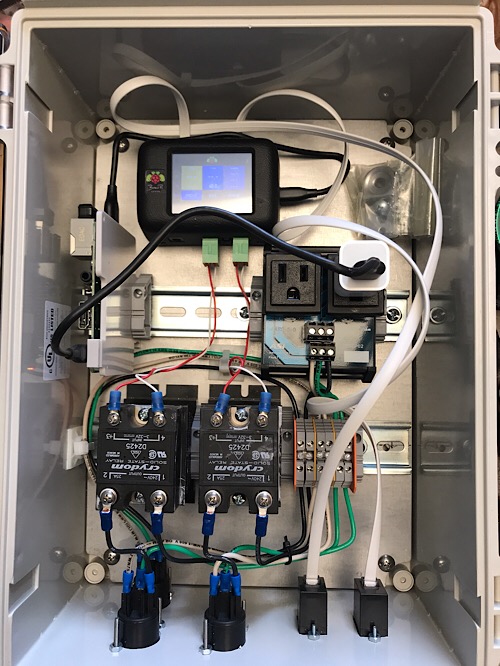

Just finished putting together the fermentation controller.

- Joined

- Oct 19, 2017

- Messages

- 1,820

- Reaction score

- 2,388

- Points

- 113

Just finished putting together the fermentation controller.

View attachment 5306

View attachment 5305

How's the BrewPi setup? Been thinking about rolling my own with a few wireless switches and CraftBeerPi, but wondering if I can be bothered working through the permutations. My setup is probably going to stay pretty simple. It would probably just end up with a single vessel electric kettle (maybe with pump for recirculation) and a single ferm chamber with a heat mat and an old kegerator for the chamber.

- Joined

- Nov 24, 2013

- Messages

- 191

- Reaction score

- 359

- Points

- 63

How's the BrewPi setup? Been thinking about rolling my own with a few wireless switches and CraftBeerPi, but wondering if I can be bothered working through the permutations. My setup is probably going to stay pretty simple. It would probably just end up with a single vessel electric kettle (maybe with pump for recirculation) and a single ferm chamber with a heat mat and an old kegerator for the chamber.

I've been happy with it, my old arduino one died, so moved my fermentation fridge setup over to the conical, bought a new one for the fermentation fridge. I think Elco is maybe a couple months off releasing a stable version to handle brew day process. I have a guy in my club who just put together a craftbeerpi setup for his electric system an appears happy with it so far.

- Joined

- Mar 12, 2019

- Messages

- 1

- Reaction score

- 2

- Points

- 3

- Joined

- Jan 13, 2019

- Messages

- 2

- Reaction score

- 0

- Points

- 1

I recently moved and had the opportunity to upgrade and jumped at the chance. I also finished my basement around the brewery and followed the theme throughout.

Last edited:

first time post for me, just a couple of low cost additions to my brewery, living in south Africa with a warm climate makes chilling my wort time consuming,I made a cheap wort chiller from 2 sizes of refrigeration piping, 1 tap and a couple of house pipe connectors plus pipe fittings, this cooks my wort from around 75 degrees to 25 in less than 15 min.

also I have a low cost draught system made up of 5 lt mini kegs with grey bugs drilled to take a 30mm long car valve, I use 16gram co2 canisters as used in cycling along with the regulators used to fill the bike tyres. fits easily in the fridge and serves cold draught

ale on demand.

ale on demand.

also I have a low cost draught system made up of 5 lt mini kegs with grey bugs drilled to take a 30mm long car valve, I use 16gram co2 canisters as used in cycling along with the regulators used to fill the bike tyres. fits easily in the fridge and serves cold draught

- Joined

- Mar 16, 2017

- Messages

- 1,616

- Reaction score

- 1,854

- Points

- 113

Be careful the steam capture doesn’t leave DMS in your wort. That being said.... sweet set up!

Ready to roll. I use a boil kettle condenser to capture steam - works great and eliminates need for a vent hood.

Last edited:

- Joined

- Dec 3, 2017

- Messages

- 2

- Reaction score

- 3

- Points

- 3

My beerage collage (I cant help myself) - in line pump holding up after 2 years

- Joined

- Jan 11, 2019

- Messages

- 3

- Reaction score

- 14

- Points

- 3

How hard was it to remove the chimb from the keg? How did you do that? I'm thinking angle grinder with a cut wheel, starting from the inside of the rim. I would worry about cutting through the main vessel if I started from the outside.Ok so below is my newly converted keggle and all in one brew rig using Biab Bag for mashing so also got the pump for recirculation. Below is my c overworked underpaid canine sniffer dog brew assistant Brittany AKA pain in the arse get hairs in my mash water and so forth brew assistant! It never ceases to amaze where hairs turn up!

- Joined

- Sep 3, 2017

- Messages

- 3

- Reaction score

- 14

- Points

- 3

- Joined

- Sep 5, 2015

- Messages

- 3,792

- Reaction score

- 7,374

- Points

- 113

Very nice!Finished the Basement, and made it a brewery!

- Joined

- Mar 14, 2018

- Messages

- 11,113

- Reaction score

- 20,859

- Points

- 113

Wow! I have Brewhouse envy, big timeFinished the Basement, and made it a brewery!

- Joined

- Sep 3, 2017

- Messages

- 3

- Reaction score

- 14

- Points

- 3

Thanks! Was a job to convince the wife!!

- Joined

- Sep 3, 2017

- Messages

- 3

- Reaction score

- 14

- Points

- 3

It is - don’t get how anyone could hate that smellNo doubt is that an exhaust hood to vent the smell of the mash and the boil that we all love, but everyone else in our houses hates?