- Joined

- Jun 16, 2020

- Messages

- 13

- Reaction score

- 22

- Points

- 3

Anywho, the pics should describe what I’m trying to do.

3 white neutral wires are not in the diagram as they will be connected together with a wire nut and stuffed away. How does it look?

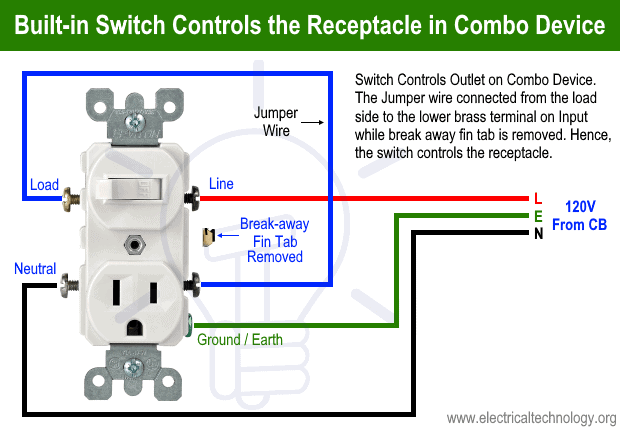

The best way to do the ground is to make a pigtail - two "jumpers" tied off to the incoming ground with a wire nut. You will need to do this with both the neutrals and the hots as well. See the image below for the switched outlet wiring diagram.Ok, leaving male ends intact sounds good. Pretty much limited to only this if I do cut them. As far as the jumper ground, I’ve heard conflicting opinions...But either way, I could. Now if I leave the male ends intact, how to wire the double switch/outlet? Would it be one double unit or 2 single switch/outlet?

pumps are around 1.4amps/each

Switch/outlet:Ok, leaving male ends intact sounds good. Pretty much limited to only this if I do cut them. As far as the jumper ground, I’ve heard conflicting opinions...But either way, I could. Now if I leave the male ends intact, how to wire the double switch/outlet? Would it be one double unit or 2 single switch/outlet?

pumps are around 1.4amps/each

Oops, these...

View attachment 11104

Sorry, no.can you draw a diagram?

Sorry, no.

I mean no offence at all, but if you need help with wiring that is this simple, you really shouldn't attempt it on your own.

Exactly! Everything downstream of the tech would be protected - including the switches. However, if you ever use one that isn't a tech then nothing is... Your choice.If your main power source (wall outlet) is already equipped with gfci protection, skip it on your made up box

Lecky = Electrician in the Aussie dialectFWIW I just got a Lecky to wire in a 15Amp 240v outlet to my patio (where I brew) he wired in a fuse should I F things up.

I'm hard core DIY but remember with electricity sometimes you don't get a second chance...

TOUCH WOOD says i