Next piece my freezer seal. I had a heart in the mouth moment when I picked up the parcel the seal was half size it was folded over. Few!

now to remove the old one and get this one installed I recon I'll drink the beer first to help me think. Lol

now to remove the old one and get this one installed I recon I'll drink the beer first to help me think. Lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you get delivered today

- Thread starter Ozarks Mountain Brewery

- Start date

I use tungsten carbide tip auger bits from good old China for this but your limited to one size recon the step drill bits would be a goer.I got 5' of 3/8" silicone hose, enough to finish off the plumbing of the electric brewery.... Waiting on the step bit to start porting my kettle!

- Joined

- Feb 3, 2018

- Messages

- 3,798

- Reaction score

- 7,000

- Points

- 113

Just got 2 lbs. of Willamette, 8 oz. of Crystal hops and 3 packets of Mangrove Jack's New World Strong Ale yeast from Yakima Valley Hops. They packed a little felt banner with it instead of the stickers you usually get with orders.

Now gotta find a way of attaching it to the fermentation fridge amongst the few other pieces of promotional $hit

Now gotta find a way of attaching it to the fermentation fridge amongst the few other pieces of promotional $hit

- Joined

- Mar 14, 2018

- Messages

- 11,208

- Reaction score

- 21,012

- Points

- 113

55# bag of 2row, and 3 packs of US-05, part of a bulk buy through my home brew club. Also have a couple pounds of Citra coming from another club bulk buy. I am sooooo stocked up now!

- Joined

- Feb 3, 2018

- Messages

- 3,798

- Reaction score

- 7,000

- Points

- 113

I hope you have better luck with those valves than I had. They had a tendency to leak around the shafts when in the on position. After replacing several, finally got pissed off and just replaced them with barbed nipples. No more leaks.

I recently ordered on of those there gas line splitters all with them little red valves I'll be keeping a close eye on em when I finally get it up and running.I hope you have better luck with those valves than I had. They had a tendency to leak around the shafts when in the on position. After replacing several, finally got pissed off and just replaced them with barbed nipples. No more leaks.View attachment 5811

Well getting more excited now about my Keezer build more parts came today yay!

. 2.6kg co2 filled cylinder I went for the smaller one so can sit it in my freezer and makes for filling easier (had my 6kg freeze up at the HB store once so couldn't fill it).

.4 way gas manifold 5 if I wack a barb on the end of it.

. 30 Meters of 4mm ID 8mm OD gas line! Plenty now plus the smaller internal diameter will mean I won't need to use so much for equalization or something. But pain in arse to fit on barbs.

. Some clear vinyl tubing for gas lines more flexy.

Some grey disconnects with MFL threads so can use them push fittings on the liquid posts were sold out dam it!

Got a one way valve gunna put this before regulator. Apparently them manifolds have an in built one way valve??

And two intertaps as a replacement for the pro's cheap arse taps he had on in appreciation for his loan of his keggerator over these years.

Oh and finally some CaCL2

Questions

. What fans do youse use in your keezer links please .

.

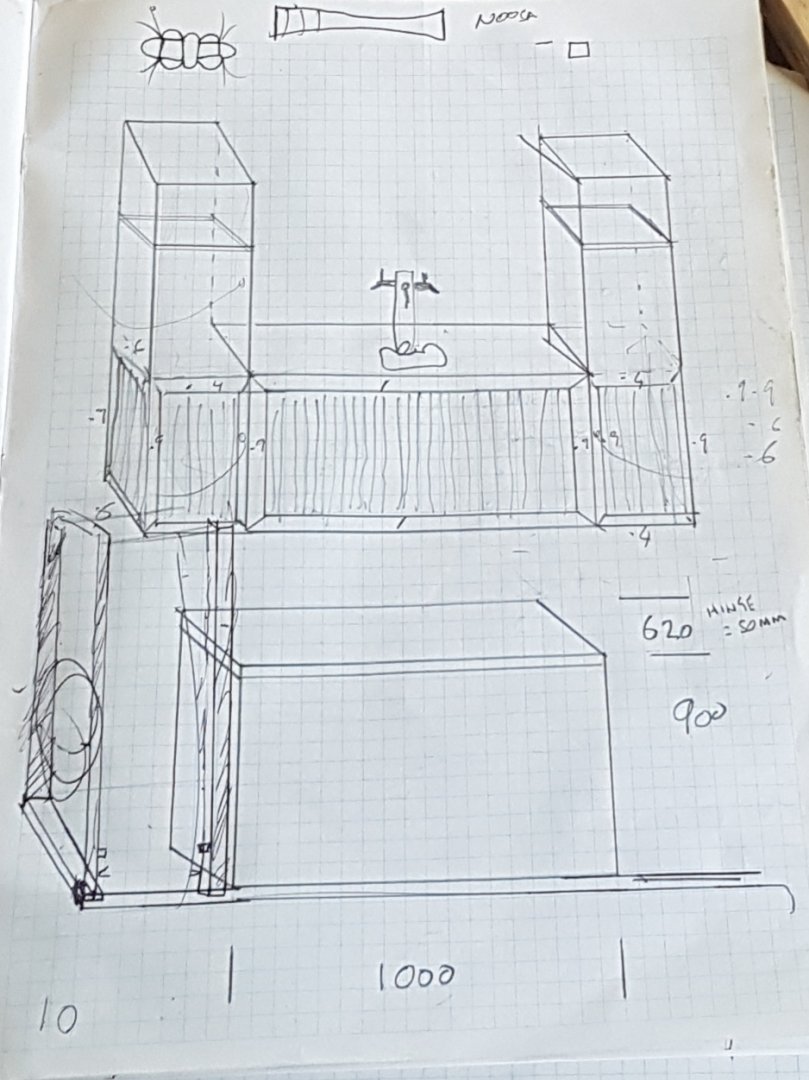

. What's your temp probe placement ideah (in a bottle of water)?

Also got me timber to build my keezer frame here is me sketch on what I've got in my head atm. Gunna do mini orb cladding framed by hardwood decking edging like my sink I built but from freezer lid up will be some sorta ply /hardwood sheeting. I want to somehow store all my HB crap in these shelves/draws. I was thinking of using them plastic storage boxes as draws. My ideah being I can pull the whole draw out on brew day to use what I need and being plastic if they get too much mouldy wort on them I can just rinse them out let em dry and put them back.

Up top I'll just have shelves. Across the middle as a header I was thinking a bit of cross cut log style timber with Ben's Bar carved / burnt into it.

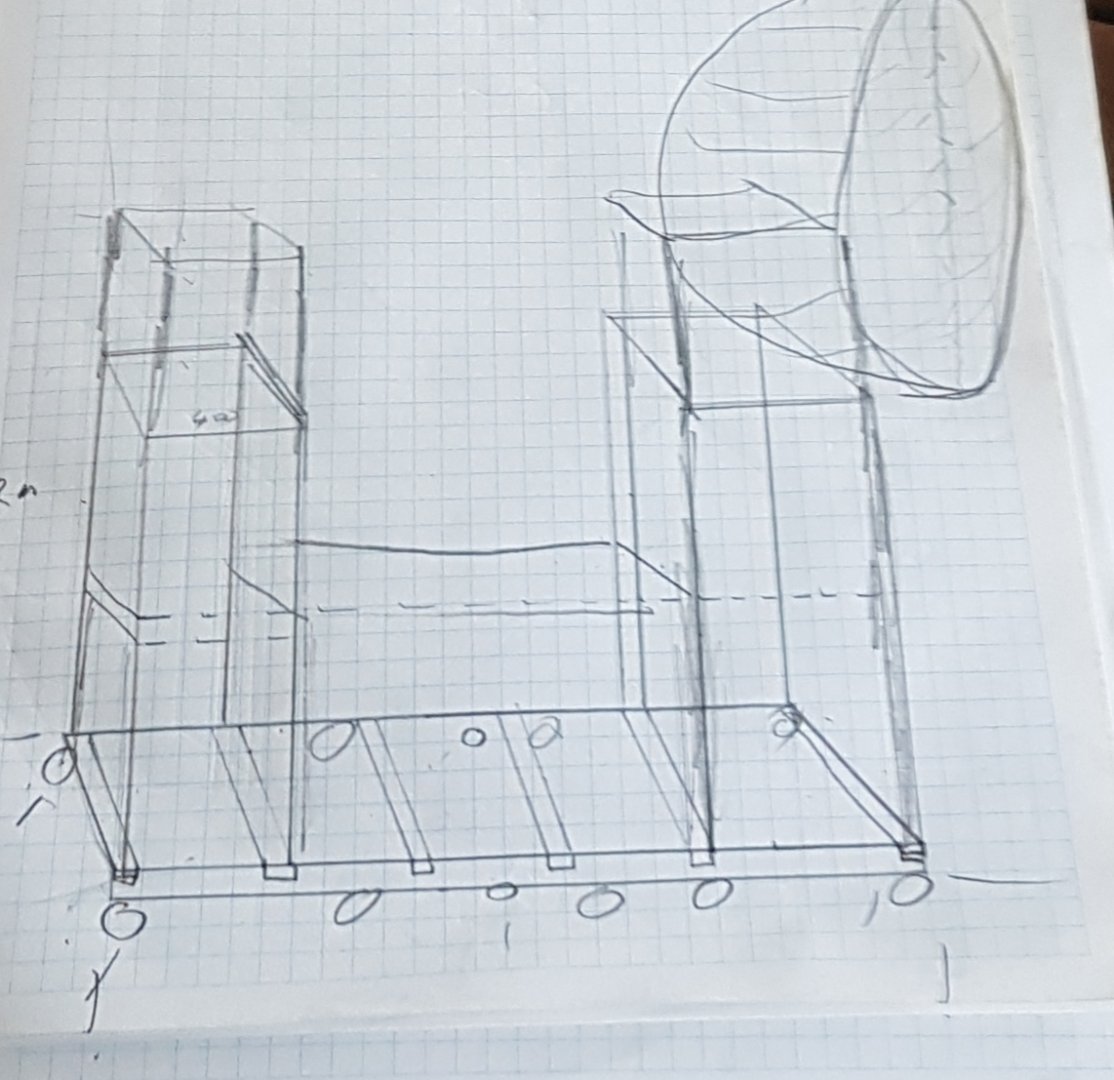

Here's me frame crude drawing but you get the gist. The whole things on castors so can wheel it out for cleaning and such.

let us know your thoughts. Maybe I should start a keezer build thread?

let us know your thoughts. Maybe I should start a keezer build thread?

. 2.6kg co2 filled cylinder I went for the smaller one so can sit it in my freezer and makes for filling easier (had my 6kg freeze up at the HB store once so couldn't fill it).

.4 way gas manifold 5 if I wack a barb on the end of it.

. 30 Meters of 4mm ID 8mm OD gas line! Plenty now plus the smaller internal diameter will mean I won't need to use so much for equalization or something. But pain in arse to fit on barbs.

. Some clear vinyl tubing for gas lines more flexy.

Some grey disconnects with MFL threads so can use them push fittings on the liquid posts were sold out dam it!

Got a one way valve gunna put this before regulator. Apparently them manifolds have an in built one way valve??

And two intertaps as a replacement for the pro's cheap arse taps he had on in appreciation for his loan of his keggerator over these years.

Oh and finally some CaCL2

Questions

. What fans do youse use in your keezer links please

. What's your temp probe placement ideah (in a bottle of water)?

Also got me timber to build my keezer frame here is me sketch on what I've got in my head atm. Gunna do mini orb cladding framed by hardwood decking edging like my sink I built but from freezer lid up will be some sorta ply /hardwood sheeting. I want to somehow store all my HB crap in these shelves/draws. I was thinking of using them plastic storage boxes as draws. My ideah being I can pull the whole draw out on brew day to use what I need and being plastic if they get too much mouldy wort on them I can just rinse them out let em dry and put them back.

Up top I'll just have shelves. Across the middle as a header I was thinking a bit of cross cut log style timber with Ben's Bar carved / burnt into it.

Here's me frame crude drawing but you get the gist. The whole things on castors so can wheel it out for cleaning and such.

- Joined

- May 12, 2018

- Messages

- 814

- Reaction score

- 825

- Points

- 93

You might think about making the bottom as rigid as possible. You don't want it to be floppy. Maybe make a box and turn those slats on edge then glue them up to the top and bottom to make a hard sandwich. I made a workbench once for a router table, planer, morticing tool. The base is made of a sandwich of particle board. The inside is slats running both ways tied together with slots and glued up to the bottom and top. Solid as a rock. 8 foot long and only needs casters on the ends.

You might think about making the bottom as rigid as possible. You don't want it to be floppy. Maybe make a box and turn those slats on edge then glue them up to the top and bottom to make a hard sandwich. I made a workbench once for a router table, planer, morticing tool. The base is made of a sandwich of particle board. The inside is slats running both ways tied together with slots and glued up to the bottom and top. Solid as a rock. 8 foot long and only needs casters on the ends.

Yeah was wondering if I should turn them timbers on their side for extra strength my castors are 100x80 plate size. Timber I'm using is 70x35mm so would be stronger if timber runs edgeways that's why I had extra castor in middle. But your right I'll do this anything is only as strong as it's base

- Joined

- Dec 22, 2012

- Messages

- 2,285

- Reaction score

- 2,612

- Points

- 113

Good advice Chico. Also make sure the casters are rated for the weight. When you add grain, beer, co2 tank and lots of hardwood it adds up fast.

Boiling water makes lines fit easier.

And remember to leave required air circulation to compressor or it wont perform well and will overheat.

As far as temp probe you will get all kinds of answers but I just hang mine in the air among the kegs and it works fine. Give it at least 3 degrees swing temp for longer compressor runs so it will last longer for ya.

And get a few dove tails and such showing to fancy it up. I'm sure you are capable.

Boiling water makes lines fit easier.

And remember to leave required air circulation to compressor or it wont perform well and will overheat.

As far as temp probe you will get all kinds of answers but I just hang mine in the air among the kegs and it works fine. Give it at least 3 degrees swing temp for longer compressor runs so it will last longer for ya.

And get a few dove tails and such showing to fancy it up. I'm sure you are capable.

Dove tails! Hey hey I'm just an a mature here headfirst. Hey thanks for the heads up on compressor circulation. I've allowed 20mm each side of the lid to the cabinet going to use one of them door weather strips to cover the up gap.Good advice Chico. Also make sure the casters are rated for the weight. When you add grain, beer, co2 tank and lots of hardwood it adds up fast.

Boiling water makes lines fit easier.

And remember to leave required air circulation to compressor or it wont perform well and will overheat.

As far as temp probe you will get all kinds of answers but I just hang mine in the air among the kegs and it works fine. Give it at least 3 degrees swing temp for longer compressor runs so it will last longer for ya.

And get a few dove tails and such showing to fancy it up. I'm sure you are capable.

What I might do is not sheet the cabinet all the way down past the lid that way plenty of circulation for compressor .

This is progress so far.

Hey them castors are rated at 60kg does that mean a combined weight using 4castors allows for 240kg. Your right there is going to be some weight sitting on them.

- Joined

- Dec 22, 2012

- Messages

- 2,285

- Reaction score

- 2,612

- Points

- 113

Look at that! Already have dados! Next step is dovetail!Dove tails! Hey hey I'm just an a mature here headfirst. Hey thanks for the heads up on compressor circulation. I've allowed 20mm each side of the lid to the cabinet going to use one of them door weather strips to cover the up gap.

What I might do is not sheet the cabinet all the way down past the lid that way plenty of circulation for compressor .

This is progress so far. View attachment 5826

Hey them castors are rated at 60kg does that mean a combined weight using 4castors allows for 240kg. Your right there is going to be some weight sitting on them.

- Joined

- Jun 13, 2017

- Messages

- 759

- Reaction score

- 1,135

- Points

- 93

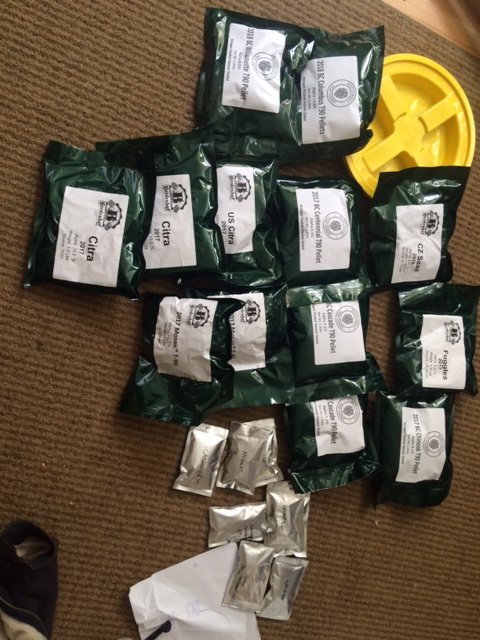

Went for a little camping trip with the family to a campground near Harrison Lake BC, had to go through the Fraser Valley!........there are hop farms there!!!

Made a couple stops, did a tour of the facility picked up some hops and was given some samples as well!

Big shout out to Brendenhof Hop farms and NorthWest Hop Farms, great people!!

Made a couple stops, did a tour of the facility picked up some hops and was given some samples as well!

Big shout out to Brendenhof Hop farms and NorthWest Hop Farms, great people!!

- Joined

- May 12, 2018

- Messages

- 814

- Reaction score

- 825

- Points

- 93

I have that same Kettle. It's a good one. I have a trick for sealing the spigot that doesn't involve a thousand wraps of Teflon tape. I'll take a picture when I get home. It has to do with silicon sealant and a washer.

Unless that thing is welded ...

Unless that thing is welded ...

Last edited:

- Joined

- Dec 22, 2012

- Messages

- 2,285

- Reaction score

- 2,612

- Points

- 113

Atta Boy! You won't look back.

Noice and shiny craigerr good upgrade.