- Joined

- May 14, 2020

- Messages

- 207

- Reaction score

- 577

- Points

- 93

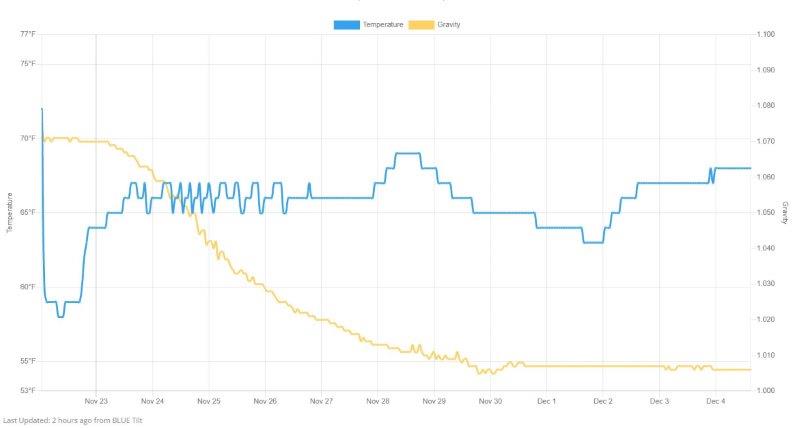

Getting ready to close transfer my Heady Topper Clone so I can bottle it.

Wyeast? Pretty good stuff.I proped open my fermentation chamber this morning when things were at about 67°... when I got home I went into my 50° cellar to find the the fungus herd going nuts at 72° and change .....holy cow! I'm not feeling too bad now about being a gallon shy ...who was asking about the Scottish Ale yeast?

aWyeast? Pretty good stuff.

Musta been that low C:N startera

Yuppers..Wyeast all hopped up on nitrogen nutrients! It's friggen brown snow globe going on! It was about a month into its 6 month shelf life so still pretty potent stuff.