You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trialbens Glycol Build.

- Thread starter GFHomebrew

- Start date

Yup and soberI really like the letter work. you did that freehand with a router?

Bro helped me out there trick is where possible to draw the router towards you.

Second cote on now to work on the top.

Ooooh! Shiny!Second cote on now to work on the top.

View attachment 18334

Looking great Ben. I think putting the text sideways was a fortuitous event. It makes it look even cooler.

Yup it makes it look like it was ment to beOoooh! Shiny!

Looking great Ben. I think putting the text sideways was a fortuitous event. It makes it look even cooler.

First coat on the top.

didn't end up putting the edging on it.

didn't end up putting the edging on it.

That thing looks sharp. Don't tell anyone else that the rotated text was a boo-boo. Tell 'em you meant it to be that way if they ask. Wouldn't be the first time I've seen sideways text. Whether it was me or the text that was sideways, I'm not sure I can divulge that information.

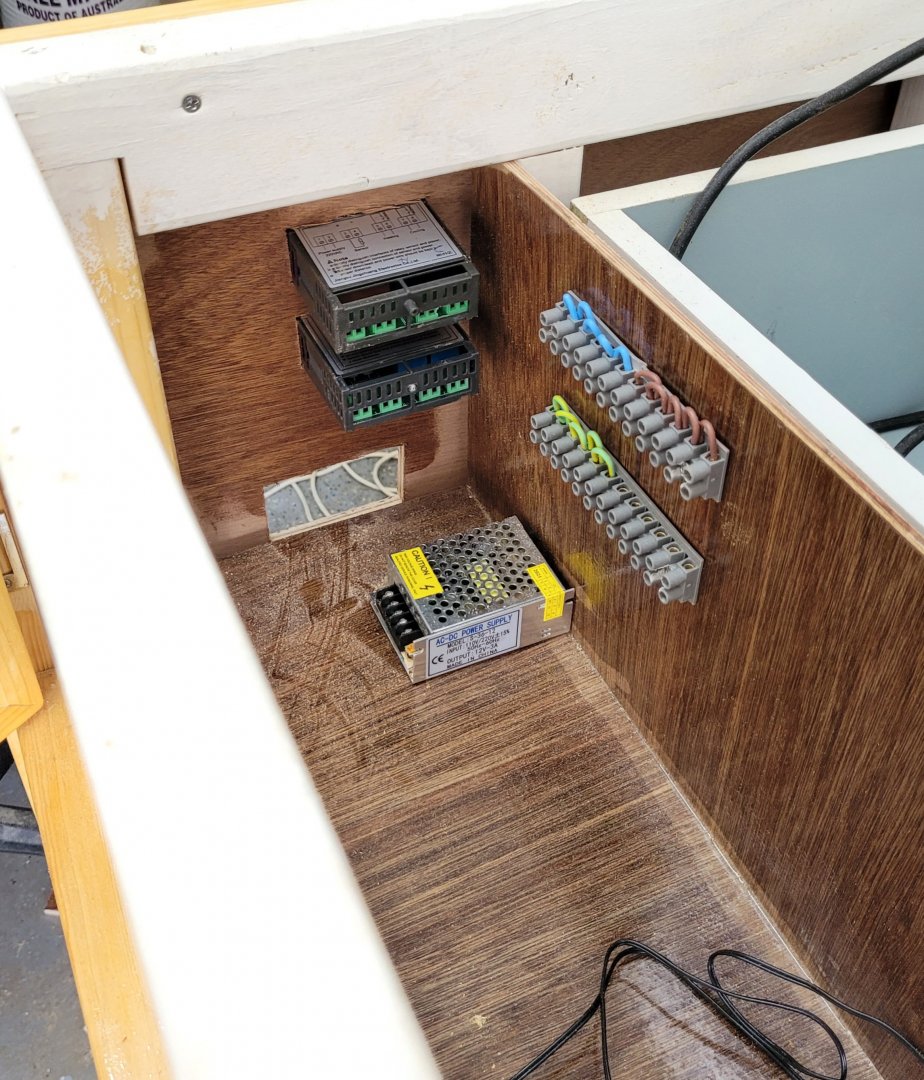

Getting some wiring done today. I gotta get this 240v one wired in and coupled to the freezer or that Amber ain't getting temp control.

240 top 12v glycol controller will be bottom

Under that is a 240v outlet

12v power supply bottom and some + neutral earth banks (don't know what their called).

Oh and not to bombard the other thread

https://www.brewersfriend.com/forum...nd-community-recipie.15249/page-5#post-153234

Yeah not sure why that switch Shat itself I think it's got something to do with this.

I plug a 15 meter extention lead into that outlet so I can brew down the other end of patio.

Now I've herd something like this that the extension lead can = some resistance and or Voltage drop on the load so maybe that's causing the trouble. Maybe I gotta have the outlet closer to where I brew and plug directly into the outlet.

Brains trust what think ye?

15Amp outlet

240 top 12v glycol controller will be bottom

Under that is a 240v outlet

12v power supply bottom and some + neutral earth banks (don't know what their called).

Oh and not to bombard the other thread

https://www.brewersfriend.com/forum...nd-community-recipie.15249/page-5#post-153234

Yeah not sure why that switch Shat itself I think it's got something to do with this.

I plug a 15 meter extention lead into that outlet so I can brew down the other end of patio.

Now I've herd something like this that the extension lead can = some resistance and or Voltage drop on the load so maybe that's causing the trouble. Maybe I gotta have the outlet closer to where I brew and plug directly into the outlet.

Brains trust what think ye?

15Amp outlet

CHECK IT OUT

Other end

Keg storage.

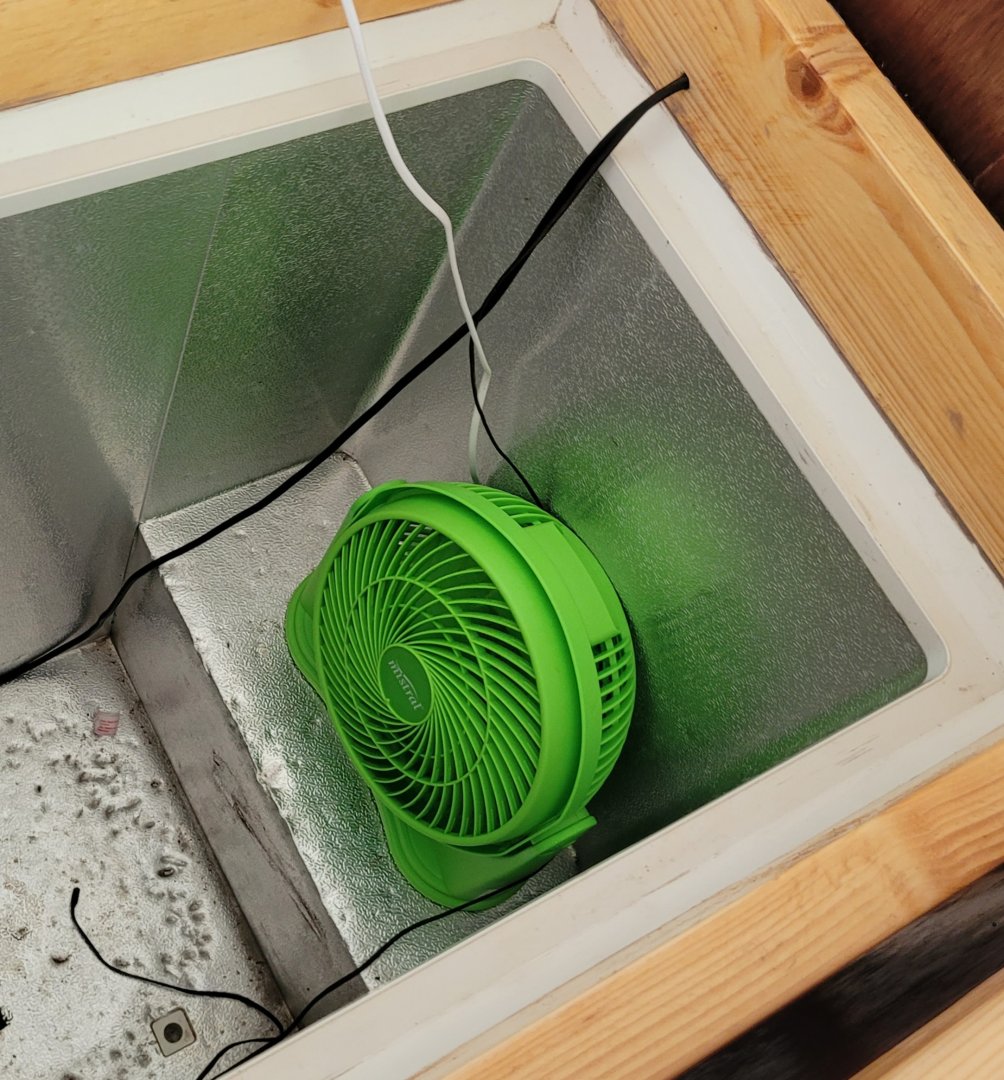

Wired in a fan to kick on with compressor

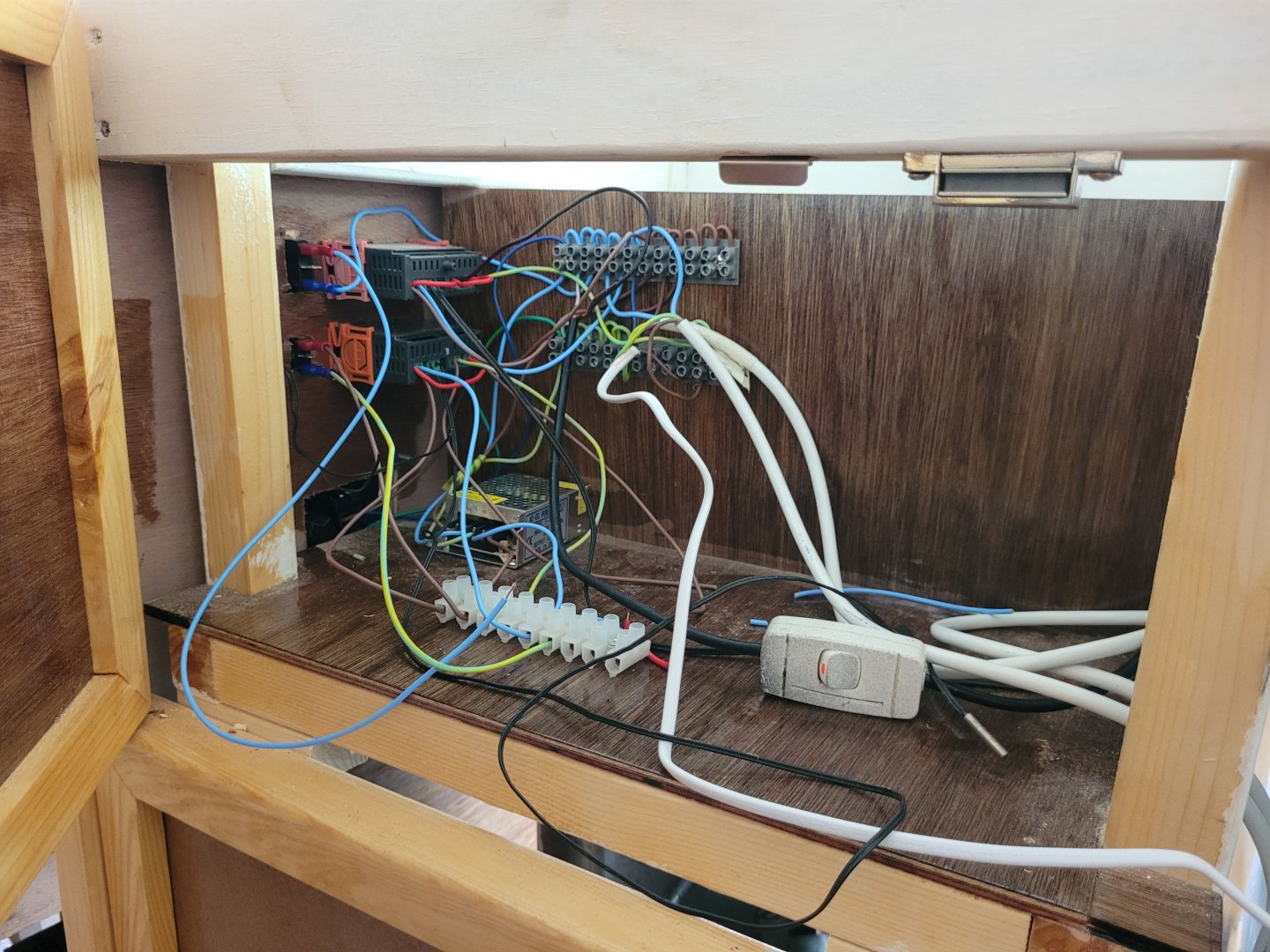

The birds nest

And it's all lockable so no one can acidentily fry themselves.

Bloody stoked with this now to get that wort transfered.

Other end

Keg storage.

Wired in a fan to kick on with compressor

The birds nest

And it's all lockable so no one can acidentily fry themselves.

Bloody stoked with this now to get that wort transfered.

The long cord can be a problem, absolutely. 15m is a long cord to be running anything much more than about 5 or 10 amps. Normally, though the cord will fail, not the switch in the kettle. The switch may not have had a high enough rating, or just simply didn't hold up. Hard to get good stuff these days.

comments @Trialben

Nice neat wiring work there Ben, happy to see that. It's called a ground bus or neutral bus. But that rats nest, that's gotta be improved: neatness counts. Get some wire ties and do it over.

The outlet died because either the pins of the cord Or the metal of the socket was not making a good electrical connection. It started arcing (sparking) and the heat generated caused the failure. Those little bits of metal worn away, surrounded by blackening? That's the telltale sign.

Lastly, a much smaller fan will do, that one seems overkill.

Nice neat wiring work there Ben, happy to see that. It's called a ground bus or neutral bus. But that rats nest, that's gotta be improved: neatness counts. Get some wire ties and do it over.

The outlet died because either the pins of the cord Or the metal of the socket was not making a good electrical connection. It started arcing (sparking) and the heat generated caused the failure. Those little bits of metal worn away, surrounded by blackening? That's the telltale sign.

Lastly, a much smaller fan will do, that one seems overkill.

comments @Trialben

Nice neat wiring work there Ben, happy to see that. It's called a ground bus or neutral bus. But that rats nest, that's gotta be improved: neatness counts. Get some wire ties and do it over.

The outlet died because either the pins of the cord Or the metal of the socket was not making a good electrical connection. It started arcing (sparking) and the heat generated caused the failure. Those little bits of metal worn away, surrounded by blackening? That's the telltale sign.

Lastly, a much smaller fan will do, that one seems overkill.

Yeah I wanted to get it sorted so I could ferment that beer.

I'll go back and neaten things up once fermentation is sorted

the fan

It was cheap has 3 speed controller you know I can't buy a little 12v one for as cheep as that. 20 bucks from the big green warehouse as opposed to 26 for a computer fan.

That one also has mounting lugs on it so I can stick it on the lid and point it down into the freezer I'm thinking.

0 to 15m you can use 10 awg wire for up to 30 amps. 15 amps you can use 14 awg. (awg to mm2 chart https://www.multicable.com/resources/reference-data/cross-reference-awg-to-mm2/) Of course there's no harm in using larger diameter wire, it'll reduce voltage drop.Now I've herd something like this that the extension lead can = some resistance and or Voltage drop on the load so maybe that's causing the trouble. Maybe I gotta have the outlet closer to where I brew and plug directly into the outlet.

Brains trust what think ye?

15Amp outlet

Yeah the extension cord is a 15 amp one. A electricitan wired that switch in as per my instructions. It's just been dicky from the start I personally don't like it's switching contacts but .0 to 15m you can use 10 awg wire for up to 30 amps. 15 amps you can use 14 awg. (awg to mm2 chart https://www.multicable.com/resources/reference-data/cross-reference-awg-to-mm2/) Of course there's no harm in using larger diameter wire, it'll reduce voltage drop.

Back to the drawing board

Thanks for the heads up

- Joined

- May 10, 2020

- Messages

- 392

- Reaction score

- 963

- Points

- 93

Just give some thought on the amount of heat produced by the fan. Might end up being counterproductive if it’s too much wind and heat, you might end up with a mini cyclone in there.Yeah I wanted to get it sorted so I could ferment that beer.

I'll go back and neaten things up once fermentation is sorted

the fan

It was cheap has 3 speed controller you know I can't buy a little 12v one for as cheep as that. 20 bucks from the big green warehouse as opposed to 26 for a computer fan.

That one also has mounting lugs on it so I can stick it on the lid and point it down into the freezer I'm thinking.

True that well it's on low so should be good it's just to move the air around.Just give some thought on the amount of heat produced by the fan. Might end up being counterproductive if it’s too much wind and heat, you might end up with a mini cyclone in there.

It'll be more handy once I'm using it to chill the glycol I'm hoping either that or I'll get a wave maker to move the glycol around.

- Joined

- Mar 12, 2017

- Messages

- 2,684

- Reaction score

- 5,567

- Points

- 113

That looks beautiful Ben!

Much appreciated mate !That looks beautiful Ben!

Glycol resivour cleaned temp probe installed.

I think the preassure bulkhead mighta been overkill

Last edited:

OMG Massive Brain FART Moment.

I NEAR Shat myself with my near stupidty but as is my style it seems to be with this build I just mighta had beginners luck maybe maybe not with this Mistake I've made this evening trying to drill some holes in what looks to me like 4mm Stainless steel

That's my thermowell there man not a flys fart between that and the gas post.

DI$KHEAD MOMENT FOR SURE I thought until I reversed the bulkhead and fitted it in reverse to make it fit. I think this'll be OK right all its gotta do is hold pressure...

to make it fit. I think this'll be OK right all its gotta do is hold pressure...

Man not margin for error here check out the realestate on this pressure plate.

This is where I'm thinking of putting the coil bulkheads now.

Their a bit bigger diameter than the probe bulkhead.

I'm worried now lol

I mean now I bet the thermowell will be super close to the glycol coil.

You know if all goes to Sh#t I got two options

A order a new pressure lid and start from scratch (maybe best option)

B soldier on pray it works out.

C install a thermowell into side of kegmenter

(Least preferred option because I'd probably do fine just taping it to the side

Oh and one more thing just dropped the coil in man I don't think this is gunna work man can't believe i didn't check this earlier

Oh that hole I rekon took a good 30mins to drill wish me luck Boys and Girls!

I NEAR Shat myself with my near stupidty but as is my style it seems to be with this build I just mighta had beginners luck maybe maybe not with this Mistake I've made this evening trying to drill some holes in what looks to me like 4mm Stainless steel

That's my thermowell there man not a flys fart between that and the gas post.

DI$KHEAD MOMENT FOR SURE I thought until I reversed the bulkhead and fitted it in reverse

Man not margin for error here check out the realestate on this pressure plate.

This is where I'm thinking of putting the coil bulkheads now.

Their a bit bigger diameter than the probe bulkhead.

I'm worried now lol

I mean now I bet the thermowell will be super close to the glycol coil.

You know if all goes to Sh#t I got two options

A order a new pressure lid and start from scratch (maybe best option)

B soldier on pray it works out.

C install a thermowell into side of kegmenter

(Least preferred option because I'd probably do fine just taping it to the side

Oh and one more thing just dropped the coil in man I don't think this is gunna work man can't believe i didn't check this earlier

Oh that hole I rekon took a good 30mins to drill wish me luck Boys and Girls!

Last edited: