Looking goodNot finished so advice is welcome, but this is my "not quite finished" brew bar.

View attachment 25049

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show your DIY Projects

- Thread starter DanC

- Start date

There's one little screw over there on the wall where the slot is not perfectly horizontal, maybe adjust it?Not finished so advice is welcome, but this is my "not quite finished" brew bar.

View attachment 25049

No, seriously: looks excellent, I can't think of anything else you'll need. I am both impressed and jealous.

- Joined

- Jul 8, 2021

- Messages

- 54

- Reaction score

- 128

- Points

- 33

There's one little screw over there on the wall where the slot is not perfectly horizontal, maybe adjust it?

No, seriously: looks excellent, I can't think of anything else you'll need. I am both impressed and jealous.

There's one little screw over there on the wall where the slot is not perfectly horizontal, maybe adjust it?

No, seriously: looks excellent, I can't think of anything else you'll need. I am both impressed and jealous.

Allow me to post a picture of the first full brew day to prove we have a ways to go.....

All the basics are there but lots of organization work is required.

- Joined

- Mar 14, 2018

- Messages

- 11,134

- Reaction score

- 20,891

- Points

- 113

Luxurious!Not finished so advice is welcome, but this is my "not quite finished" brew bar.

View attachment 25049

- Joined

- Jan 27, 2019

- Messages

- 5,104

- Reaction score

- 11,729

- Points

- 113

OhNot finished so advice is welcome, but this is my "not quite finished" brew bar.

View attachment 25049

I like that

A lot!

You've put alot of thought into this!Allow me to post a picture of the first full brew day to prove we have a ways to go.....

All the basics are there but lots of organization work is required.

View attachment 25056

I like the sliding hoist system and the plate chiller setup just next to the sink.

A happy little place to knock out a batch of hombrew.

- Joined

- Jul 8, 2021

- Messages

- 54

- Reaction score

- 128

- Points

- 33

You've put alot of thought into this!

I like the sliding hoist system and the plate chiller setup just next to the sink.

A happy little place to knock out a batch of hombrew.

Thank you for noticing. The plate chiller is one of the lose ends. It is just sitting there. It was going to be mounted under the kettle to save space but after playing with it I really like the idea of it being very close the sink. I'm going to brew one more time before I change it but I plan on making a small mount so that it can be cleanly set next to the sink, with the pump and be able to drain with a very short hose. I'm huge fan of minimizing the amount of hose I have to manage. We will see. And regarding "alot of thought", I tend to over think and do better with doing and experimenting.....

This has been a very evolutionary process with lots of ideas coming from this forum.

You twist those? Than came out very nice.Building a railing so my dog stops jumping off the fence, my first architectural smithing project. I still need to finish the top rail but overall it's going really well. View attachment 25796

- Joined

- Mar 31, 2021

- Messages

- 4,321

- Reaction score

- 6,417

- Points

- 113

Little later to this party. But i wouldn't do. The recovery time for a mini fridge as a glycol cooler is abysmal. Tried to make mine work for like a year and gave upNot sure if the right forum , but here goes - Have an insulated box, and a mini freezer, and looking to build a copper box that closely fits the walls of the freezer as a glycol / water reservoir to chill the box. Want to put thermal conductive grease between the copper and the plastic walls, thoughts on how to build a custom copper box, and best thermal grease? Otherwise I think I’ve figured out the rest. I know all the arguments against using a mini freezer / and air, but the super-insulated box as a chill target is not the same as a standalone fermenter with a jacket. Basically creating a super-efficient keezer.

- Joined

- May 10, 2020

- Messages

- 392

- Reaction score

- 963

- Points

- 93

Well, I guess we all need to learn our own lessons. Still moving forward, very slowly, but switching to aluminum from copper for the liquid vessel, and skipping the grease. Anvil glycol pump and temp controller on order. Will primarily try to maintain cool serving temp of about 45F/7C. Probably won't work for cold crashing unless I shift the temp down very slowly. With 4" of closed cell insulation on all sides, I am optimistic it will work, but we shall see. Trying to eliminate moving ice from freezer to insulated box.Little later to this party. But i wouldn't do. The recovery time for a mini fridge as a glycol cooler is abysmal. Tried to make mine work for like a year and gave up

- Joined

- Jul 27, 2017

- Messages

- 4,764

- Reaction score

- 4,675

- Points

- 113

You twist those? Than came out very nice.

Sorry for the delay responding, yup. Each one is slightly different cause I wanted to play with technique. I need to wire wheel the top and coat it for rust but it's been so damned hot here I've had zero ambition all month.

A great winter project just gotta dig out the snowSorry for the delay responding, yup. Each one is slightly different cause I wanted to play with technique. I need to wire wheel the top and coat it for rust but it's been so damned hot here I've had zero ambition all month.

- Joined

- May 10, 2020

- Messages

- 392

- Reaction score

- 963

- Points

- 93

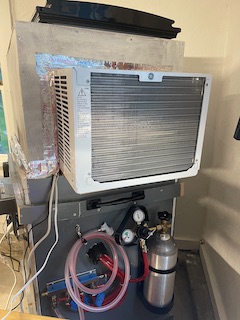

Most recent chapter in the saga of the large insulated box. Was going to turn it into a homemade keezer using a small freezer to circulate glycol. Went pretty far in fabricating an interior box to fit the small freezer, and finally realized what everyone was telling me. It would be futile given the btu output.

Switched gears and made the box taller. Tall enough to house a small air conditioner. Now I have an air conditioned box. I currently have it cycling between 40 F and 48 F, so I figure it is averaging 44 or so. Look up diy Coolbot on YouTube to get an overview of the approach.

As odd as it is, I now have a super-insulated keezer that holds three 5 gallon cornies, serving through three taps on a Perlick stainless tower (picked up for $50). No more shifting ice from one place to another, and much dryer inside.

Switched gears and made the box taller. Tall enough to house a small air conditioner. Now I have an air conditioned box. I currently have it cycling between 40 F and 48 F, so I figure it is averaging 44 or so. Look up diy Coolbot on YouTube to get an overview of the approach.

As odd as it is, I now have a super-insulated keezer that holds three 5 gallon cornies, serving through three taps on a Perlick stainless tower (picked up for $50). No more shifting ice from one place to another, and much dryer inside.

Very cool I'll go check out that video.Most recent chapter in the saga of the large insulated box. Was going to turn it into a homemade keezer using a small freezer to circulate glycol. Went pretty far in fabricating an interior box to fit the small freezer, and finally realized what everyone was telling me. It would be futile given the btu output.

Switched gears and made the box taller. Tall enough to house a small air conditioner. Now I have an air conditioned box. I currently have it cycling between 40 F and 48 F, so I figure it is averaging 44 or so. Look up diy Coolbot on YouTube to get an overview of the approach.

As odd as it is, I now have a super-insulated keezer that holds three 5 gallon cornies, serving through three taps on a Perlick stainless tower (picked up for $50). No more shifting ice from one place to another, and much dryer inside.

Any pictures of your build mate?

- Joined

- May 10, 2020

- Messages

- 392

- Reaction score

- 963

- Points

- 93

I'll post some photos in the next day or three. Working like a charm so far (about five days or so).Very cool I'll go check out that video.

Any pictures of your build mate?

Checked out thar coolbot video which lead me to coolbot alternative videos with guys running an inkbird with a light bulb on the air-conditioning sensor.I'll post some photos in the next day or three. Working like a charm so far (about five days or so).

Another guy had a temperature sensor running the air-conditioner.

Which was plugged into the hot side of an inkbird which had its sensor on the fins of the air con.

So the inkbird would cut power to the (room) temp sensor running the air con preventing it from icing up if it were running too much.

I think this is the Coolbot work around.

These Coolbots must be pricey ?

I rekon that's an awesome fermentation chamber alternative.

- Joined

- May 10, 2020

- Messages

- 392

- Reaction score

- 963

- Points

- 93

Photos of the AC Rock Box. Not pretty, but it works. An evolving construct.

- Joined

- May 10, 2020

- Messages

- 392

- Reaction score

- 963

- Points

- 93

Love it! Next project might be to modify my current ride.