- Joined

- Sep 30, 2018

- Messages

- 24

- Reaction score

- 14

- Points

- 3

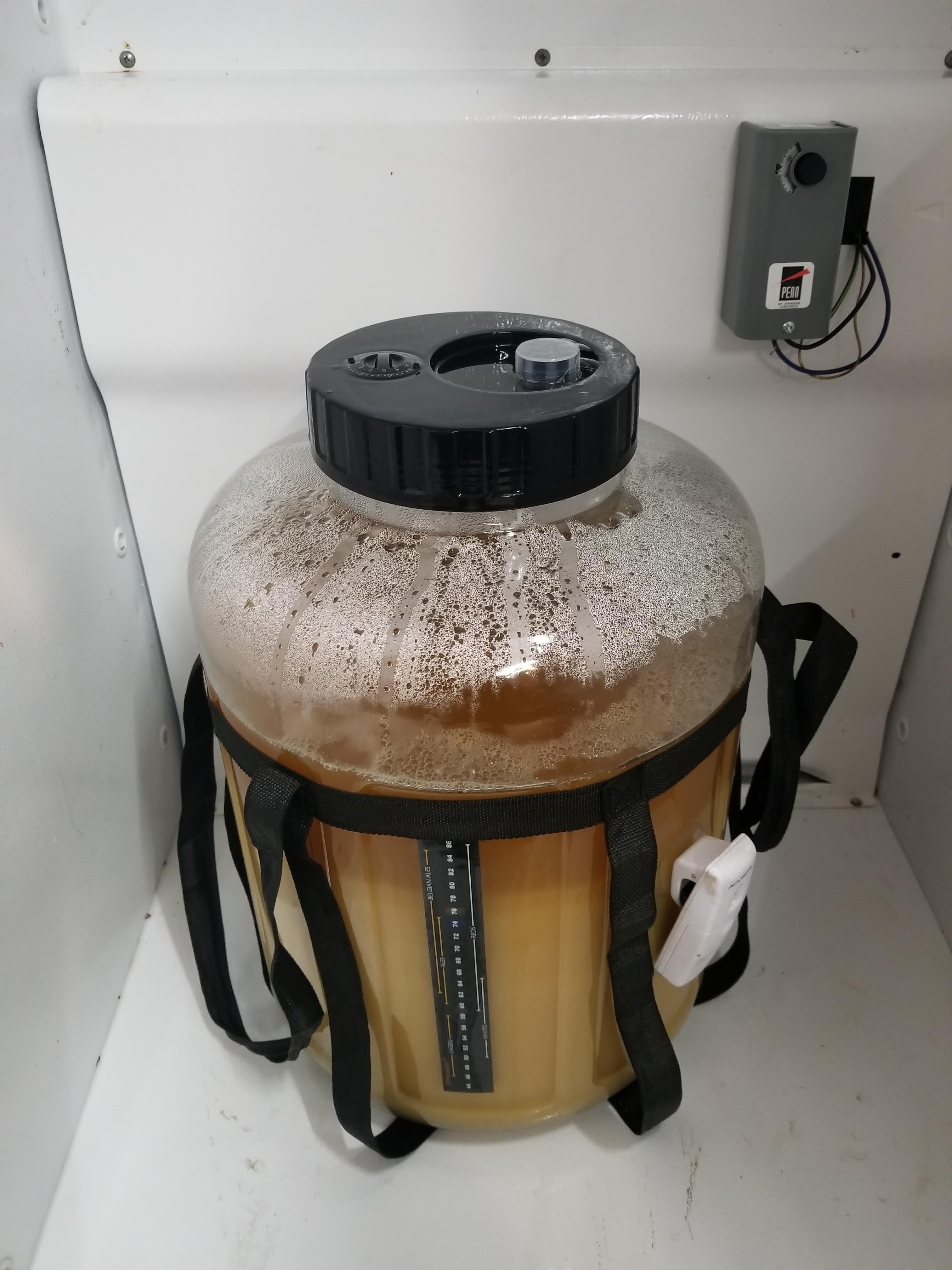

So I looked up different threads, but didn't see anything that described my situation. This is my first all grain batch and I tried making a west coast session. I made a rookie mistake and forgot to buy ice for the wort chill. I still used my immersion chiller, but couldn't get it to drop below 80. I used my auto siphon to rack to my fermentor and pitched my liquid Wyeast 1056 at 80 degrees. Where I really think I messed up is I didn't dilute the star san when I put it in the airlock and about 8 hours later, the airlock was empty and the krausen was already dying out. Now it's been 10 hours, I removed the straight star san and replaced with diluted, and the picture shows what it looks like now. Original Gravity was 1.054. How bad do you all think I've screwed up and is there any way to salvage it.