You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show your DIY Projects

- Thread starter DanC

- Start date

Starsan is quite corrosive. Just ask any aluminum pot you ever put it in. I have enough trouble with hard water that I don't want to aggravate it.I usually just add star sans and plug the ends

I've noticed that every time I chill a batch with it, it comes out super shiny on the outside. Never realized the pH of wort was acid enough to clean copper that way.

I blow as much out as I can get, then hang it upside down to drain the drips into the top bends, then, carefully pick it up to finish draining. Since it's gonna get a good boil next time I use it (10 minutes before flame out), I don't worry too much about bacteria. I hose it off after a batch to get the sticky wort off the outside, and clean it up enough to store it without it gluing itself to something. I've got a rather large immersion chiller, some 50 feet of copper tubing I rolled for the purpose.

Oh nice this way you can clean your beer transfer lines as well on the piggy back from tap to tap.Power supply In action, beer line cleaning day.

(Forgot to purge the lines first lol)

View attachment 18678

Yeah I think Ozarks response is in relation to a counterflow chiller not an imersion chillerStarsan is quite corrosive. Just ask any aluminum pot you ever put it in. I have enough trouble with hard water that I don't want to aggravate it.

I've noticed that every time I chill a batch with it, it comes out super shiny on the outside. Never realized the pH of wort was acid enough to clean copper that way.

I blow as much out as I can get, then hang it upside down to drain the drips into the top bends, then, carefully pick it up to finish draining. Since it's gonna get a good boil next time I use it (10 minutes before flame out), I don't worry too much about bacteria. I hose it off after a batch to get the sticky wort off the outside, and clean it up enough to store it without it gluing itself to something. I've got a rather large immersion chiller, some 50 feet of copper tubing I rolled for the purpose.

With the imersion chiller it doesn't matter what's in the cooling coil as it never touches your beer.

But

With a plate chiller or counterflow chiller your wort is pumped through the coil whilst your chill water is forced around the outside of the coil so the coil is best left cleaned and sanitized before reuse to avoid mould bacteria build up.

Yup I'd blow it out like @Donoroto little contraption does then pump my boiling wort through before using on brew day.

- Joined

- Mar 31, 2021

- Messages

- 4,337

- Reaction score

- 6,437

- Points

- 113

Ya. It cleans everything in one go. I checked one of the faucets, it was Shiney clean.Oh nice this way you can clean your beer transfer lines as well on the piggy back from tap to tap.

160+°F PBW under pressure for 20 minutes.

Yeah, I guess so. If I had a plate cooler, I'd probably tend to just run boiling water through it then blow it out when I was doing cleanup, and do it again before use on the next batch. Get it hot, kill the bugs. Gotta purge it with beer before capturing anyway.Yeah I think Ozarks response is in relation to a counterflow chiller not an imersion chiller.

With the imersion chiller it doesn't matter what's in the cooling coil as it never touches your beer.

But

With a plate chiller or counterflow chiller your wort is pumped through the coil whilst your chill water is forced around the outside of the coil so the coil is best left cleaned and sanitized before reuse to avoid mould bacteria build up.

Yup I'd blow it out like @Donoroto little contraption does then pump my boiling wort through before using on brew day.

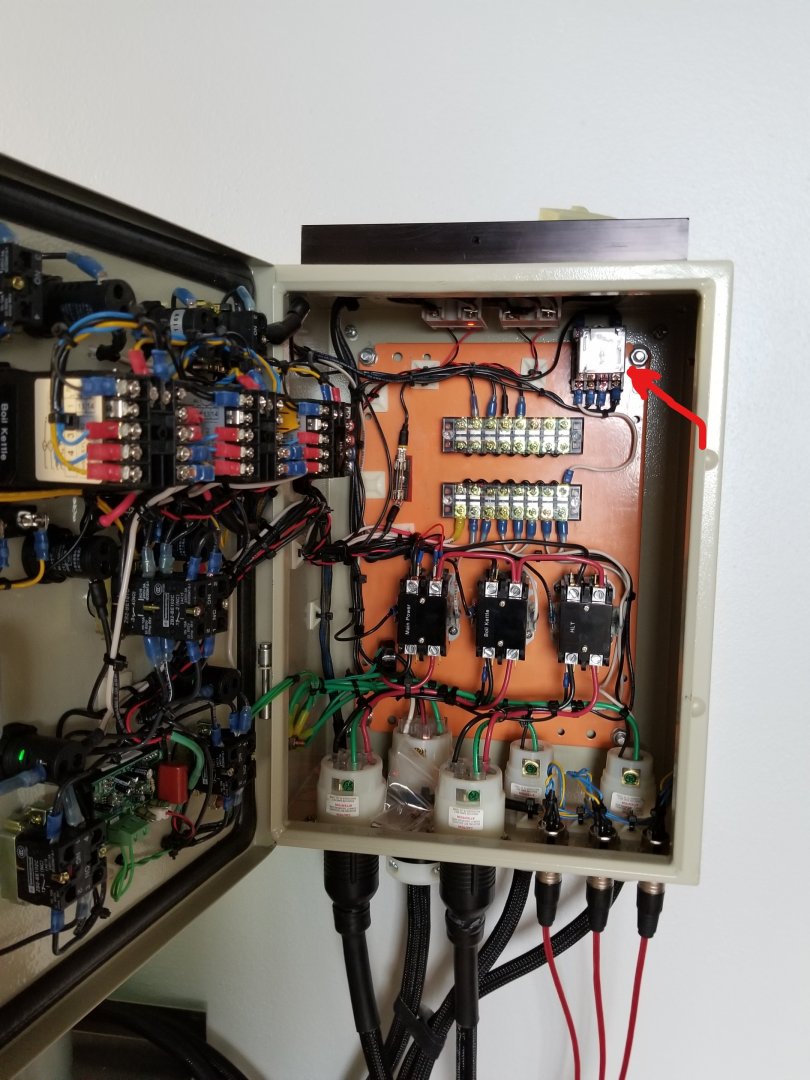

Added the safety interlock to the brewing panel so you cannot power it up with a burner or pump turned on:

Wow man that is soo neat!Added the safety interlock to the brewing panel so you cannot power it up with a burner or pump turned on:

View attachment 18924

- Joined

- Mar 24, 2018

- Messages

- 3,101

- Reaction score

- 5,932

- Points

- 113

Nice work Frosty! Who said Breadboarding is dead? What's with the single connections on the screw terminals? Future work?

- Joined

- May 10, 2019

- Messages

- 1,556

- Reaction score

- 3,506

- Points

- 113

Nice work Frosty! Who said Breadboarding is dead? What's with the single connections on the screw terminals? Future work?

If you look close they all look jumpered. Commons

Thanks, @west1m has it. I didn't have any bus bars so they're jumpered terminal blocks for all the 120v circuitsWhat's with the single connections on the screw terminals?

- Joined

- Mar 14, 2018

- Messages

- 11,192

- Reaction score

- 20,965

- Points

- 113

Only a disturbed mind could wire a panel that neatly. I have a good friend who does work like that. He is disturbed...Added the safety interlock to the brewing panel so you cannot power it up with a burner or pump turned on:

View attachment 18924

That is beautifulI spent the better part of Saturday learning how to make this out of a 4" piece of round bar. I'm pretty pleased with the outcome.

View attachment 18946

Sorta says something about my mind then my wiring (chaotic)Only a disturbed mind could wire a panel that neatly. I have a good friend who does work like that. He is disturbed...

- Joined

- Apr 14, 2019

- Messages

- 412

- Reaction score

- 1,056

- Points

- 93

I spent the better part of Saturday learning how to make this out of a 4" piece of round bar. I'm pretty pleased with the outcome.

View attachment 18946

The “Enforcer”

I guess I am disturbed <g>Only a disturbed mind could wire a panel that neatly. I have a good friend who does work like that. He is disturbed...

That's awesomeI spent the better part of Saturday learning how to make this out of a 4" piece of round bar. I'm pretty pleased with the outcome.

View attachment 18946

Right there with ya buddy.I guess I am disturbed <g>