- Joined

- Mar 23, 2018

- Messages

- 1,116

- Reaction score

- 2,171

- Points

- 113

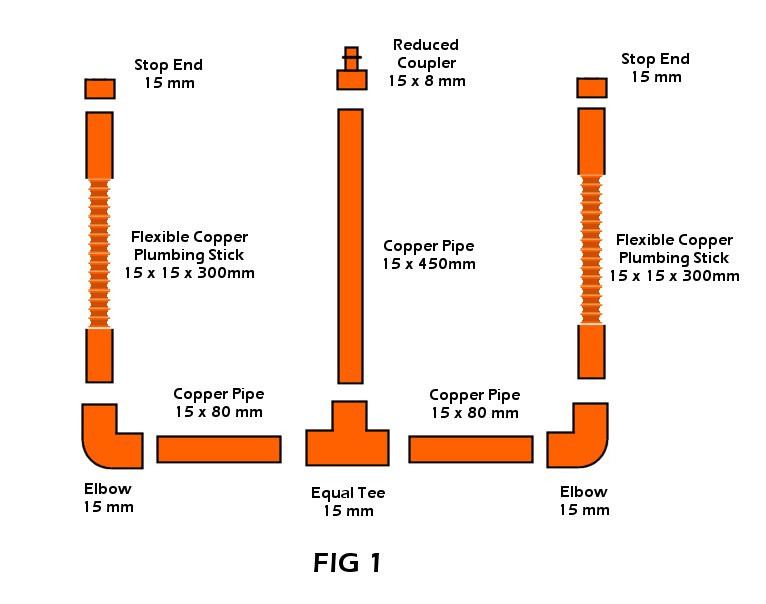

I had difficulty in sparging my first couple of brews using the "jug-at-a-time" method as it seemed to disturb the grain bed too much and, as a result, it was taking a long time for the wort to run clear. I had seen other brewers Youtube methods using copper or plastic plumbing pipework suitably drilled to produce a more even spread of sparge so I decided to have a go and make my own.

Being on a budget I had also "manufactured" my own Mash tun using a 35lt Fermentation bucket so my sparge arm had to be capable of fitting the mash tun therefore was to be circular.

The big problem is that copper pipe is hard enough to bend at t he best of times so there had to be a better way.

A trip to the local B&Q store gave me the idea of using the "bendable" copper pipes that are used to connect to sing taps so I came up with the following design.

Components:

All the bits above and some 15mm pipe were fashioned into a T shape as the basic frame with the "bendable" sticks set at opposing 90 degree angles and then bent to fit the lowest diameter of the Mashtun bin.

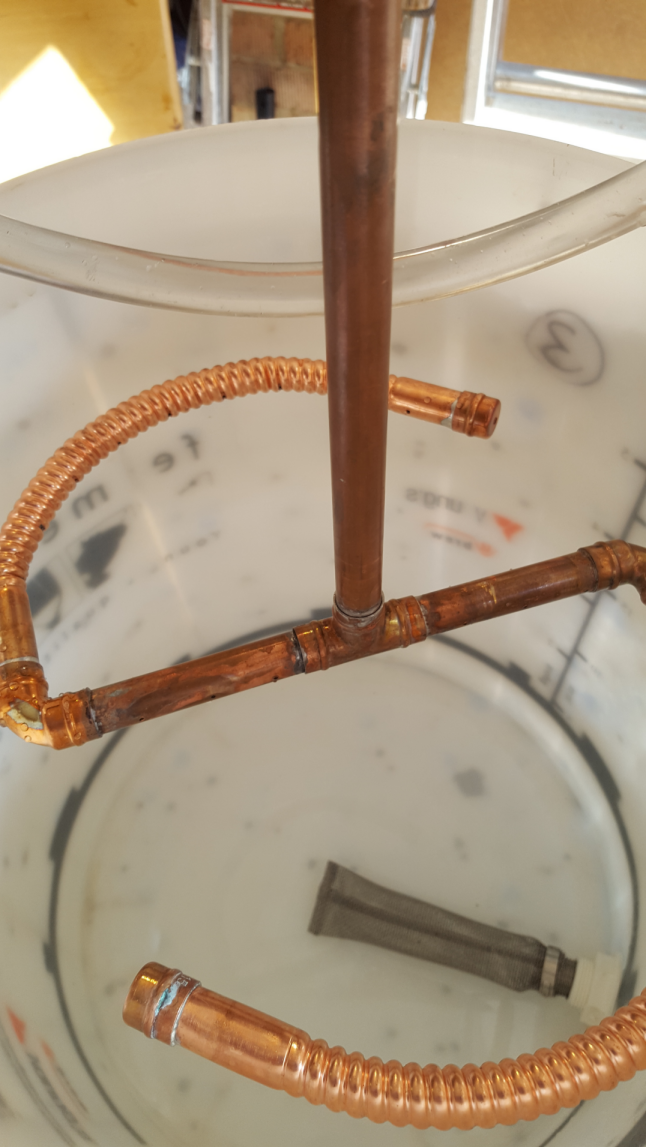

The parts detailed in figure 1 were soldered together and manipulated to end up like this:

All the lower arms, including the base of the T shape were drilled at 20mm intervals on the lower working side to produce a spread of spray across the grain bed over which the arm is suspended. I use a bespoke movable brewing frame that has 3 levels so I can gravity feed the wort and hot water at the different stages of mashing, boiling and draining into the FV after cooling the wort so I have drilled holes in the frame to hold another 25mm pipe with a T-End that supports the sparge arm in operation. The following videos show the arm in use in an early test. The hot water for the sparge is transferred into a PB that I use as the sparging source. The tap on the PB regulates the flow of water through the sparge arm. The whole unit is covered in a polystyrene shield to keep the heat in during use.

I hope this will be of some help if you are thinking of constructing a similar rig for your own brewhouse.

The Sparge arm in use:

,

Being on a budget I had also "manufactured" my own Mash tun using a 35lt Fermentation bucket so my sparge arm had to be capable of fitting the mash tun therefore was to be circular.

The big problem is that copper pipe is hard enough to bend at t he best of times so there had to be a better way.

A trip to the local B&Q store gave me the idea of using the "bendable" copper pipes that are used to connect to sing taps so I came up with the following design.

Components:

All the bits above and some 15mm pipe were fashioned into a T shape as the basic frame with the "bendable" sticks set at opposing 90 degree angles and then bent to fit the lowest diameter of the Mashtun bin.

The parts detailed in figure 1 were soldered together and manipulated to end up like this:

All the lower arms, including the base of the T shape were drilled at 20mm intervals on the lower working side to produce a spread of spray across the grain bed over which the arm is suspended. I use a bespoke movable brewing frame that has 3 levels so I can gravity feed the wort and hot water at the different stages of mashing, boiling and draining into the FV after cooling the wort so I have drilled holes in the frame to hold another 25mm pipe with a T-End that supports the sparge arm in operation. The following videos show the arm in use in an early test. The hot water for the sparge is transferred into a PB that I use as the sparging source. The tap on the PB regulates the flow of water through the sparge arm. The whole unit is covered in a polystyrene shield to keep the heat in during use.

I hope this will be of some help if you are thinking of constructing a similar rig for your own brewhouse.

The Sparge arm in use:

Last edited: