Hello brewers! I would like to update/remake my recirculation arm/sparge arm on my mash tun setup. What's everybody using? Do you like it? What would you change? I've looked into PVC, but it's not rated for 150-160' F. Right now I use a short length of silicon tubing, but it doesn't get the coverage that I want. I appreciate everyone's suggestions!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sparge/recirculation arms

- Thread starter Sunfire96

- Start date

- Joined

- Mar 31, 2021

- Messages

- 3,236

- Reaction score

- 5,124

- Points

- 113

I use this, works like a charm

Loc-Line - 51837 Coolant Hose Circle Flow Nozzle Kit, 16 Piece, 1/2" Hose ID https://a.co/d/auNjksl

Loc-Line - 51805 Coolant Hose Component, Acetal Copolymer, Connector, 1/2" Hose ID, 1/2" NPT (Pack of 4) https://a.co/d/bVP15CX

Loc-Line - 51837 Coolant Hose Circle Flow Nozzle Kit, 16 Piece, 1/2" Hose ID https://a.co/d/auNjksl

Loc-Line - 51805 Coolant Hose Component, Acetal Copolymer, Connector, 1/2" Hose ID, 1/2" NPT (Pack of 4) https://a.co/d/bVP15CX

- Joined

- Jun 27, 2019

- Messages

- 2,394

- Reaction score

- 7,124

- Points

- 113

I have no idea what a Sparge arm is, but CPVC (not PVC) has the temperature range you are looking for.Hello brewers! I would like to update/remake my recirculation arm/sparge arm on my mash tun setup. What's everybody using? Do you like it? What would you change? I've looked into PVC, but it's not rated for 150-160' F. Right now I use a short length of silicon tubing, but it doesn't get the coverage that I want. I appreciate everyone's suggestions!

As an aside and with no intentions of sidetracking here, but does your Mash tun hold temperature constant? Is it even necessary to recirculate and Sparge? I’m honestly curious. What’s the gain…the cost-benefit ratio? I swear that I’m not trying to be a jerk (at least, this time).

I looked into CPVC, but wasn't sure if chlorine would eventually leach out and into the beerI have no idea what a Sparge arm is, but CPVC (not PVC) has the temperature range you are looking for.

As an aside and with no intentions of sidetracking here, but does your Mash tun hold temperature constant? Is it even necessary to recirculate and Sparge? I’m honestly curious. What’s the gain…the cost-benefit ratio? I swear that I’m not trying to be a jerk (at least, this time).As a simple BIAB’er, I‘m just trying to understand. Are there clear differences between a beer mashed and left alone vs. one mashed, recirculated and rinsed? I find this stuff fascinating.

My mash tun does not hold a temp well, and I also like to use my stove top burner to increase the temp for step mashing. Adding any insulation would singe/burn while the burner is on. I like to recirculate during the heating phases to prevent scorching on the bottom of the kettle. I don't think constant recirculation improves extract efficiency, in my personal experience. It's also useful to recirculate as a vorlauf before lautering to the boil kettle

I'm looking for an arm that will disperse the liquid over the grain bed without creating channels in the grain or aerating the wort and creating foam.

What's the temperature rating on that? Is it easy to work with, like disassembling and configuring the shape?I use this, works like a charm

Loc-Line - 51837 Coolant Hose Circle Flow Nozzle Kit, 16 Piece, 1/2" Hose ID https://a.co/d/auNjksl

Loc-Line - 51805 Coolant Hose Component, Acetal Copolymer, Connector, 1/2" Hose ID, 1/2" NPT (Pack of 4) https://a.co/d/bVP15CX

- Joined

- Mar 31, 2021

- Messages

- 3,236

- Reaction score

- 5,124

- Points

- 113

If you have a very well insulated mash tun. Maybe it is unnecessary.I have no idea what a Sparge arm is, but CPVC (not PVC) has the temperature range you are looking for.

As an aside and with no intentions of sidetracking here, but does your Mash tun hold temperature constant? Is it even necessary to recirculate and Sparge? I’m honestly curious. What’s the gain…the cost-benefit ratio? I swear that I’m not trying to be a jerk (at least, this time).As a simple BIAB’er, I‘m just trying to understand. Are there clear differences between a beer mashed and left alone vs. one mashed, recirculated and rinsed? I find this stuff fascinating.

I do BIAB and use the boil pot. Will not hold heat for anything. So recirc keeps the temp within 3F for the whole time.

Last edited:

- Joined

- Jun 27, 2019

- Messages

- 2,394

- Reaction score

- 7,124

- Points

- 113

Thanks for that. I can certainly understand recirculating to avoid hot/cold spots if temperatures fluctuate and you apply heat. I do the same. My recirculating arm is my right, with a spoon, while my left lifts the lid.I looked into CPVC, but wasn't sure if chlorine would eventually leach out and into the beer

My mash tun does not hold a temp well, and I also like to use my stove top burner to increase the temp for step mashing. Adding any insulation would singe/burn while the burner is on. I like to recirculate during the heating phases to prevent scorching on the bottom of the kettle. I don't think constant recirculation improves extract efficiency, in my personal experience. It's also useful to recirculate as a vorlauf before lautering to the boil kettle

I'm looking for an arm that will disperse the liquid over the grain bed without creating channels in the grain or aerating the wort and creating foam.

- Joined

- Mar 31, 2021

- Messages

- 3,236

- Reaction score

- 5,124

- Points

- 113

Rated to 180F.What's the temperature rating on that? Is it easy to work with, like disassembling and configuring the shape?

All the little pieces snap together and can be made in any shape you want. they do snap very hard, so disassembling for cleaning is not practical. You can run a brush through it if you want.

Cleaning is just running pbw through it when I clean the herms coil, etc.

Thanks for answering. The reason I ask is because that's the sparge arm that Brew Hardware recommends, but they caution its difficult to take apart and sell a separate tool for disassemblyRated to 180F.

All the little pieces snap together and can be made in any shape you want. they do snap very hard, so disassembling for cleaning is not practical. You can run a brush through it if you want.

Cleaning is just running pbw through it when I clean the herms coil, etc.

- Joined

- Mar 31, 2021

- Messages

- 3,236

- Reaction score

- 5,124

- Points

- 113

Lol, that's called stirring. I still do that a few timeThanks for that. I can certainly understand recirculating to avoid hot/cold spots if temperatures fluctuate and you apply heat. I do the same. My recirculating arm is my right, with a spoon, while my left lifts the lid.

- Joined

- Mar 31, 2021

- Messages

- 3,236

- Reaction score

- 5,124

- Points

- 113

You can get them apart with a pliers, but they do snap hard. I used a bench vice and pliers and it was cake.Thanks for answering. The reason I ask is because that's the sparge arm that Brew Hardware recommends, but they caution its difficult to take apart and sell a separate tool for disassembly

On the upside, you only have to do it once

- Joined

- Mar 14, 2018

- Messages

- 9,050

- Reaction score

- 16,437

- Points

- 113

I like this!How mine is setup

- Joined

- Mar 14, 2018

- Messages

- 9,050

- Reaction score

- 16,437

- Points

- 113

I am working out a DYI setup myself right now, this was my inspiration

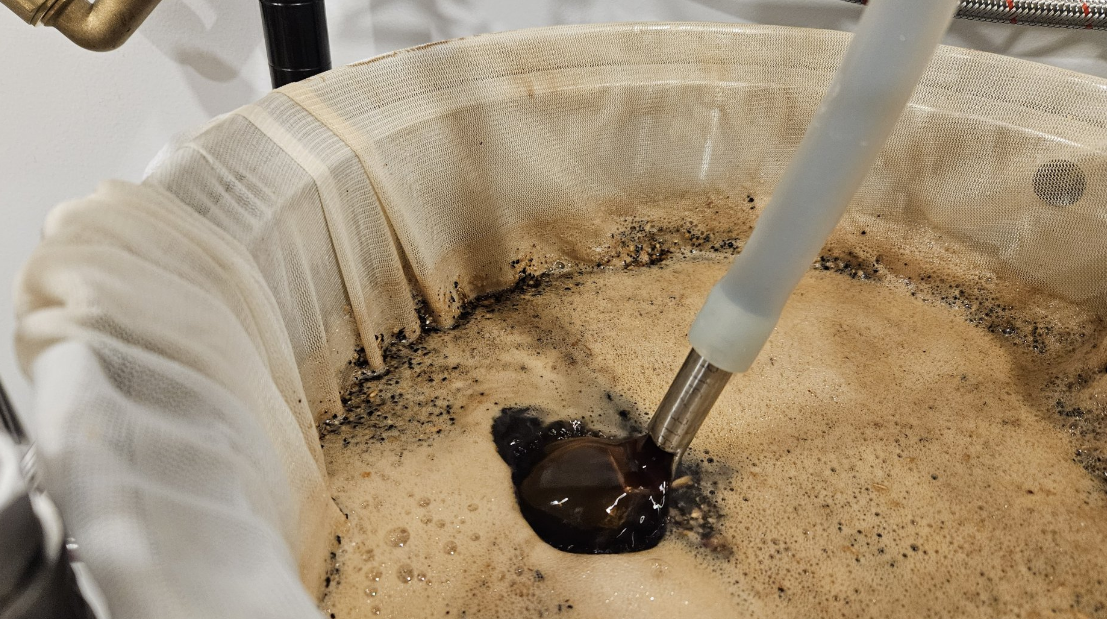

This is how it worked for me this morning, needs further development.

I used a rotary tool to cut a piece of stainless tubing and used a ball peen hammer to shape it.

Hose was too long (spreader too close to top of wort), and the silicon tube ain't exactly straight so I couldn't really center it, or get it to hang plumb.

It is hanging from the sparge arm on a Brewzilla.

It worked well enough, but I hope to have a better arrangement for the next brew.

This is how it worked for me this morning, needs further development.

I used a rotary tool to cut a piece of stainless tubing and used a ball peen hammer to shape it.

Hose was too long (spreader too close to top of wort), and the silicon tube ain't exactly straight so I couldn't really center it, or get it to hang plumb.

It is hanging from the sparge arm on a Brewzilla.

It worked well enough, but I hope to have a better arrangement for the next brew.

That's a cool idea Craig. I'm unable to hang anything above my kettle. So I'm limited to what I can attach to the 1/2 inch ball valve at the top of my kettleI am working out a DYI setup myself right now, this was my inspiration

View attachment 28213

This is how it worked for me this morning, needs further development.

I used a rotary tool to cut a piece of stainless tubing and used a ball peen hammer to shape it.

Hose was too long (spreader too close to top of wort), and the silicon tube ain't exactly straight so I couldn't really center it, or get it to hang plumb.

It is hanging from the sparge arm on a Brewzilla.

It worked well enough, but I hope to have a better arrangement for the next brew.

View attachment 28214

- Joined

- Mar 31, 2021

- Messages

- 3,236

- Reaction score

- 5,124

- Points

- 113

I tried that, but it does channel alotI am working out a DYI setup myself right now, this was my inspiration

View attachment 28213

This is how it worked for me this morning, needs further development.

I used a rotary tool to cut a piece of stainless tubing and used a ball peen hammer to shape it.

Hose was too long (spreader too close to top of wort), and the silicon tube ain't exactly straight so I couldn't really center it, or get it to hang plumb.

It is hanging from the sparge arm on a Brewzilla.

It worked well enough, but I hope to have a better arrangement for the next brew.

View attachment 28214

- Joined

- Jul 19, 2019

- Messages

- 2,079

- Reaction score

- 5,104

- Points

- 113

Would this work?I looked into CPVC, but wasn't sure if chlorine would eventually leach out and into the beer

My mash tun does not hold a temp well, and I also like to use my stove top burner to increase the temp for step mashing. Adding any insulation would singe/burn while the burner is on. I like to recirculate during the heating phases to prevent scorching on the bottom of the kettle. I don't think constant recirculation improves extract efficiency, in my personal experience. It's also useful to recirculate as a vorlauf before lautering to the boil kettle

I'm looking for an arm that will disperse the liquid over the grain bed without creating channels in the grain or aerating the wort and creating foam.

https://m.media-amazon.com/images/W/MEDIAX_849526-T2/images/I/41PfqisqIRL._SX522_.jpg

- Joined

- Mar 14, 2018

- Messages

- 9,050

- Reaction score

- 16,437

- Points

- 113

That would be ideal!

Could you send a link to that on amazon, that just links to a picture.

- Joined

- Jul 19, 2019

- Messages

- 2,079

- Reaction score

- 5,104

- Points

- 113

I just searched Mash Tun sprayer on amazon