You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

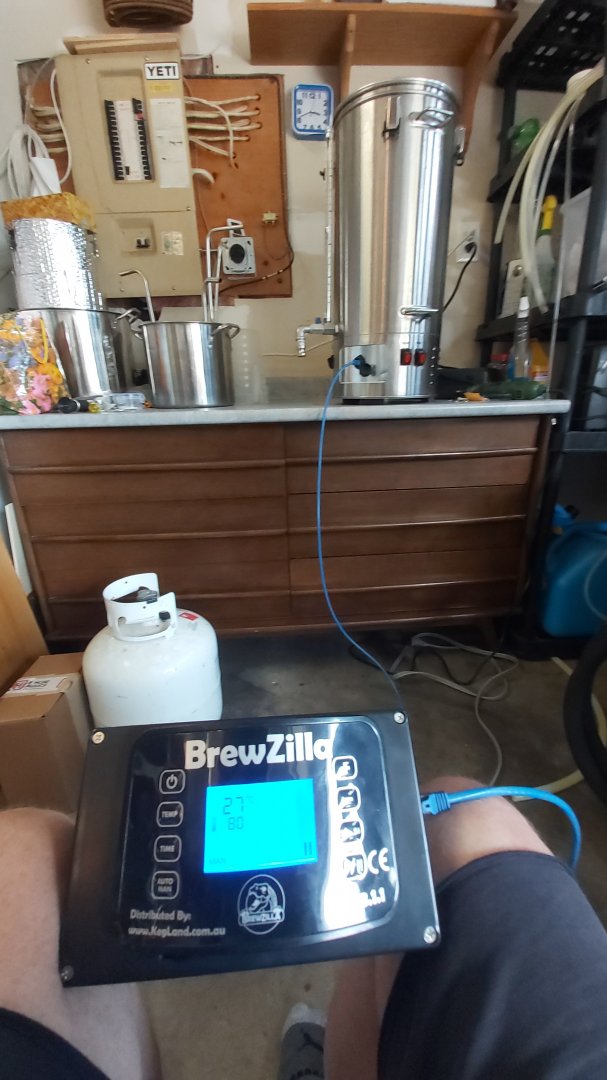

Brewzilla Remote Controller

- Thread starter Craigerrr

- Start date

Indeed, very nice!

- Joined

- Mar 14, 2018

- Messages

- 9,038

- Reaction score

- 16,412

- Points

- 113

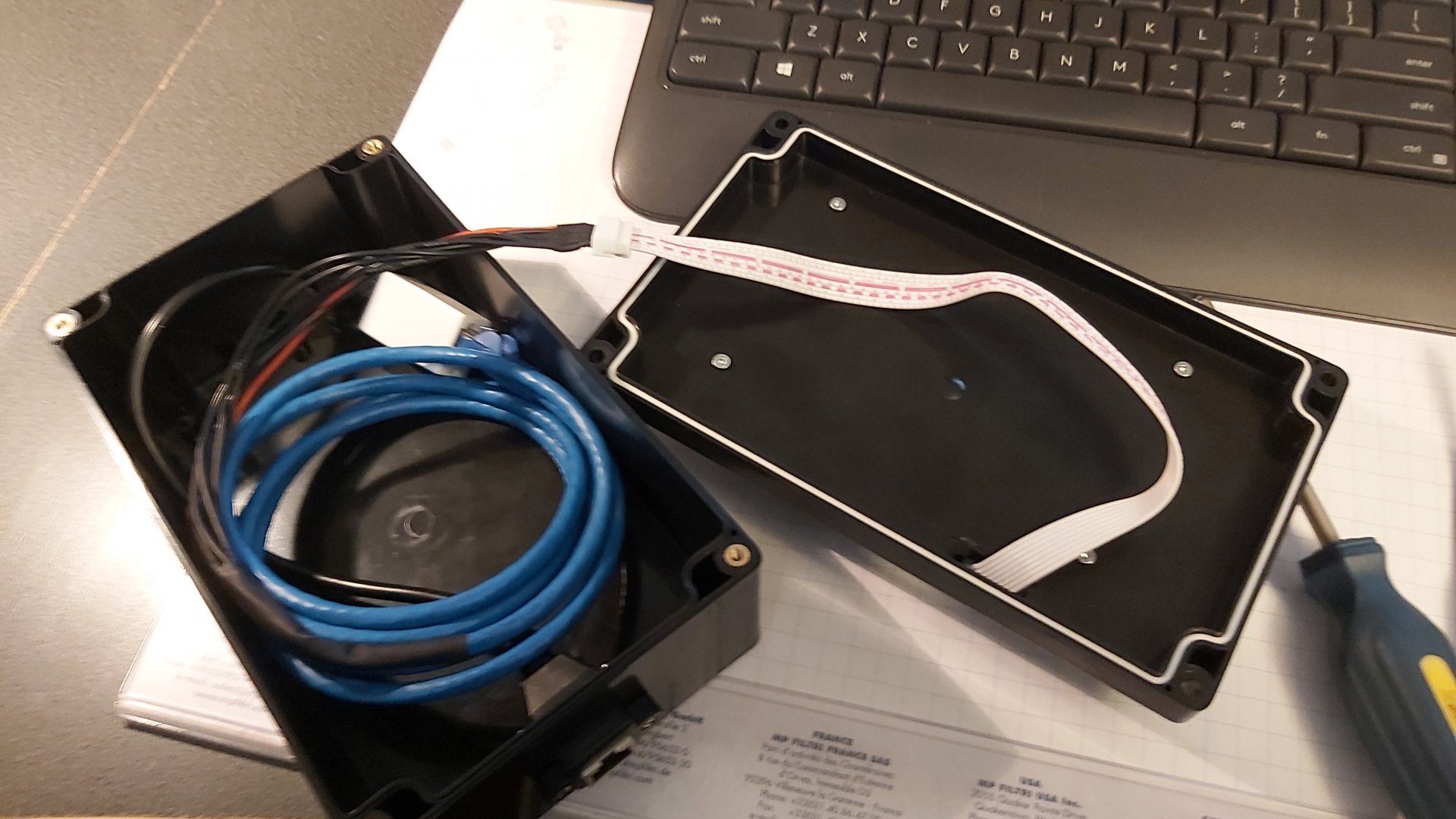

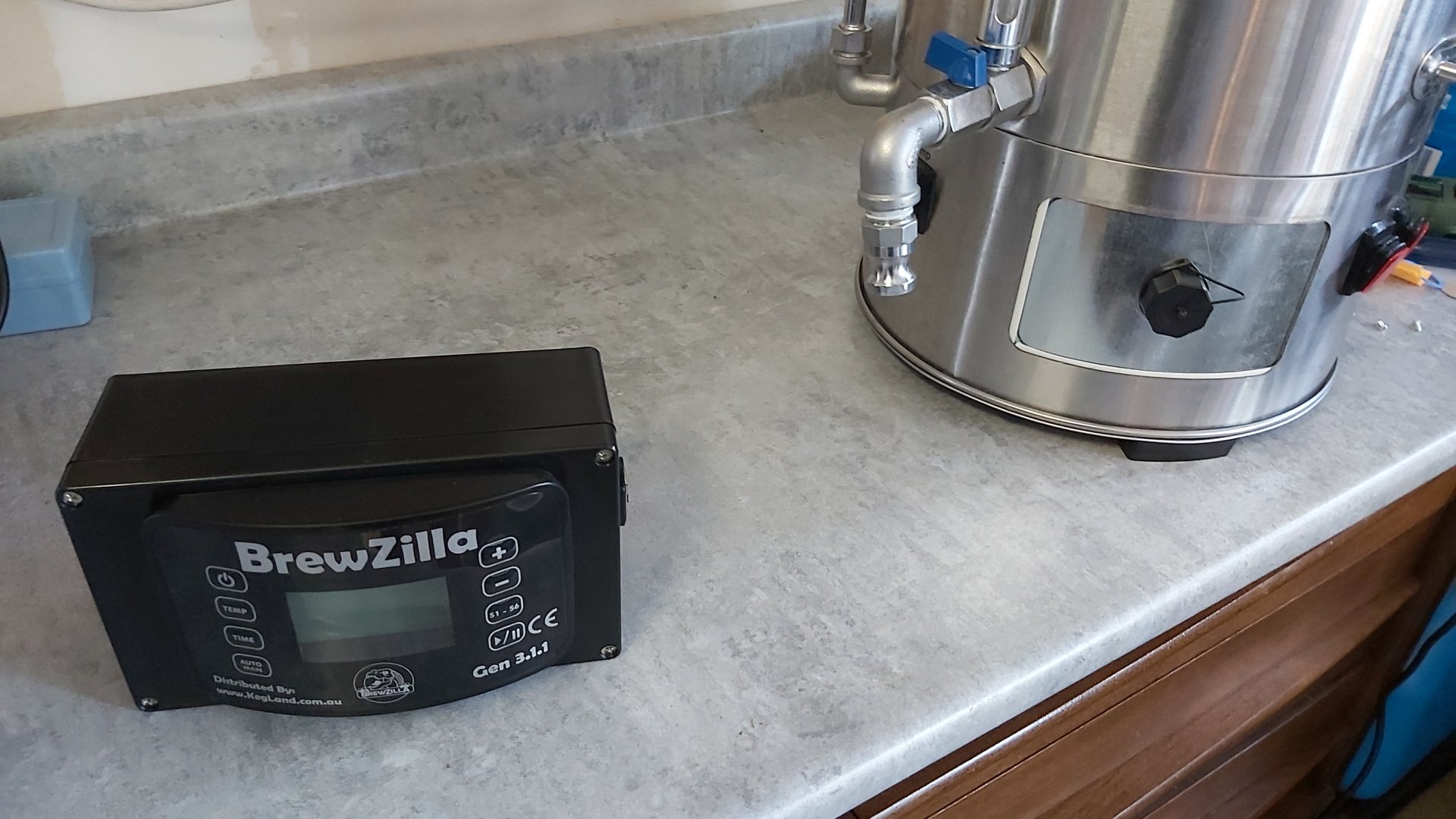

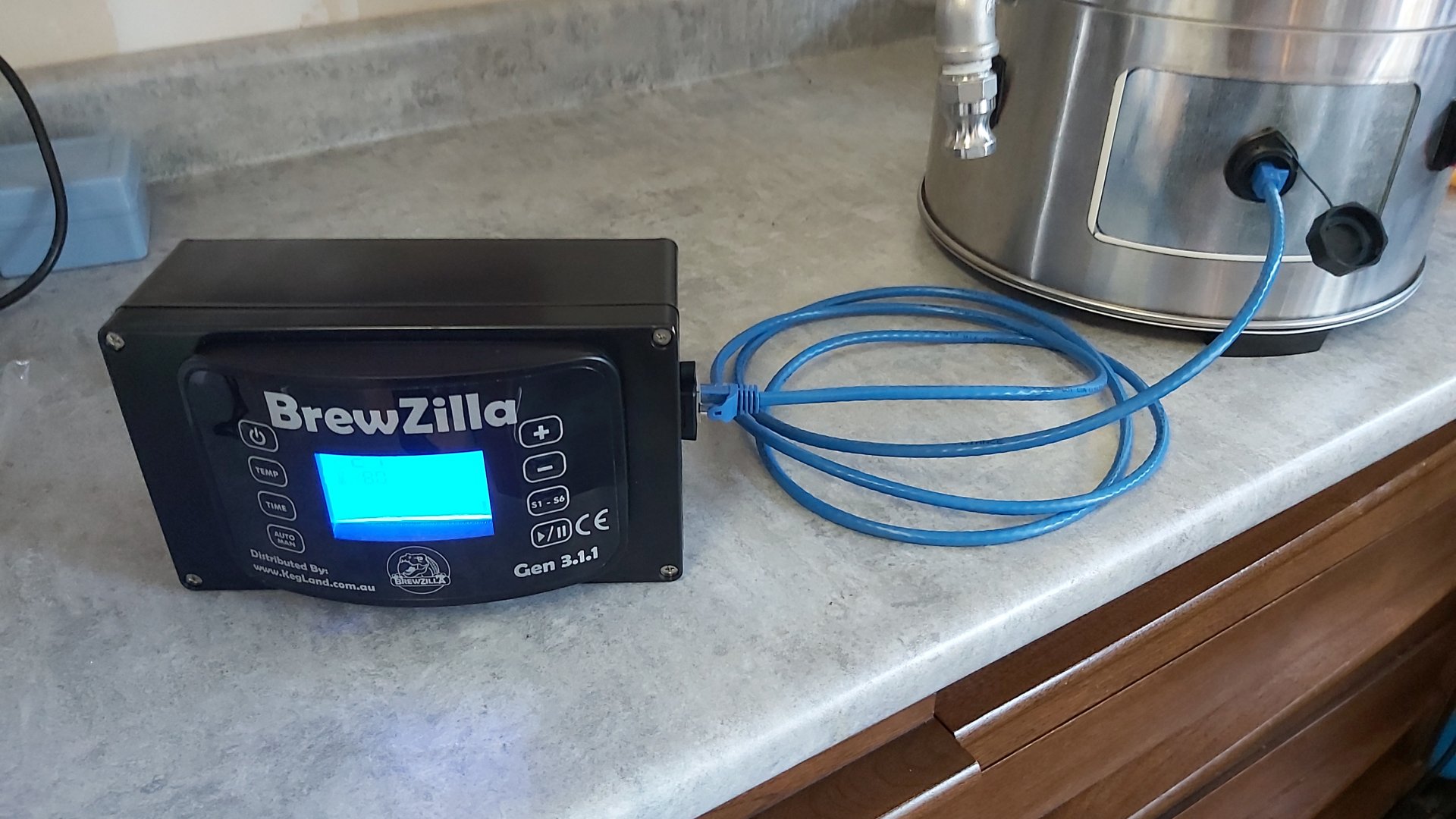

Okay, haven't gotten to finishing this up until now, here is the finished product.

Only thing I have left to tidy up is a weatherproof connector cover for the Cat5 cable end that connects to the machine.

I have it, just need to cut the cable, then splice back together.

Used two of the six screws to keep the two haves of the control module together, then used four longer screws to fasten the module to the lid of the panel box.

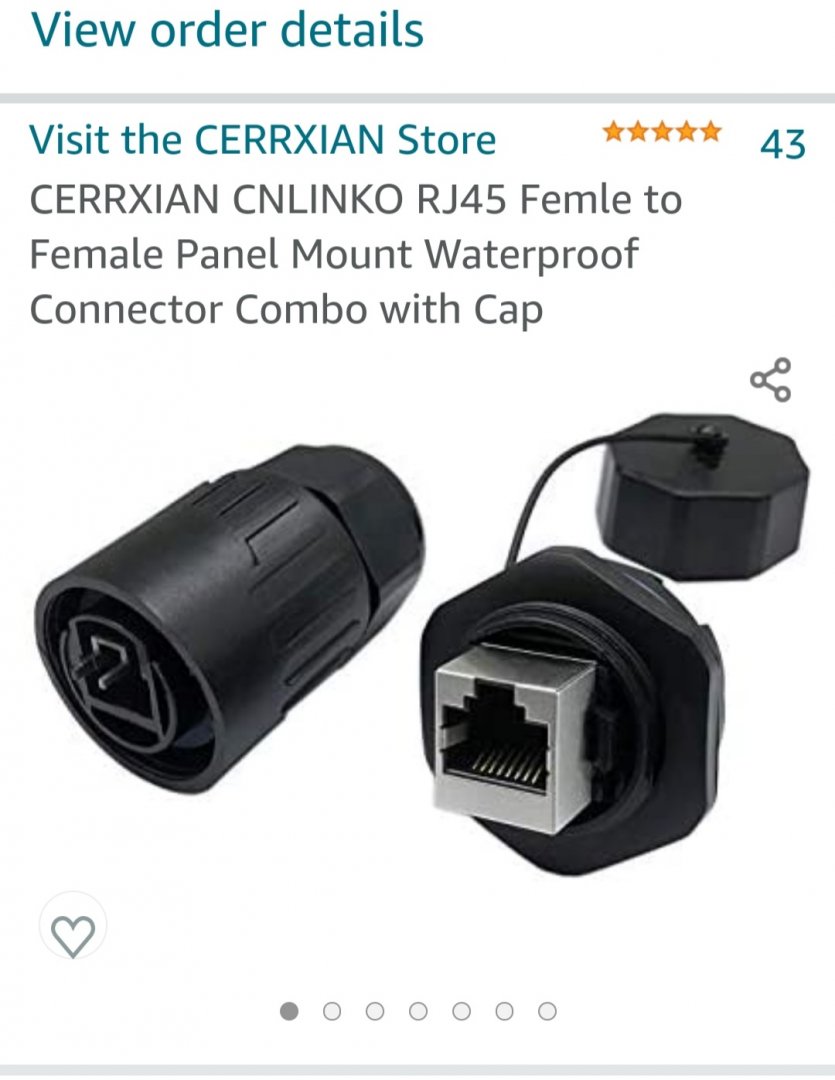

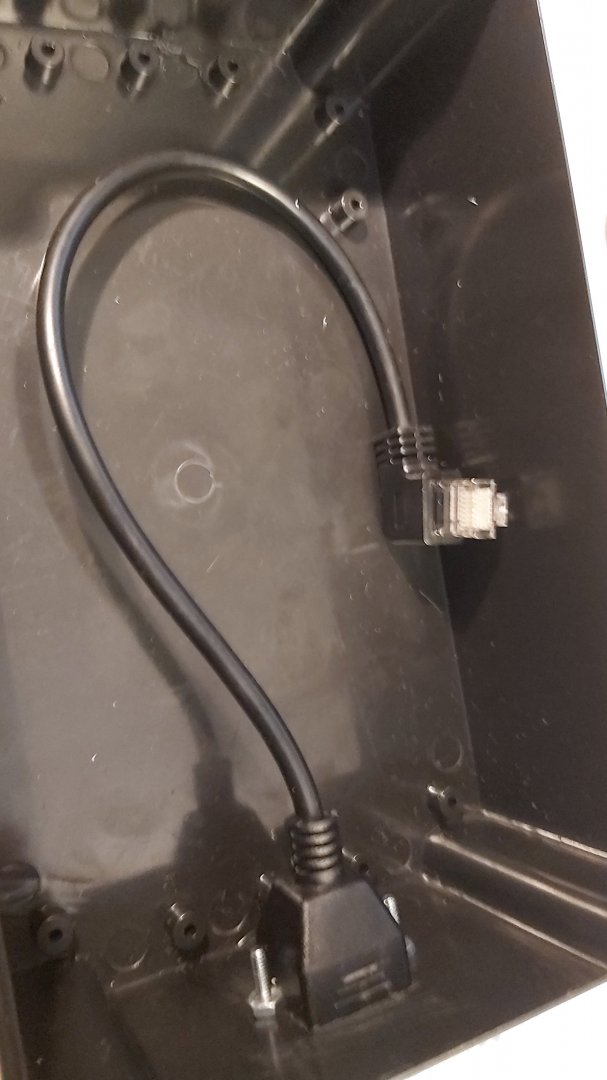

Cut a hole in the side of the panel box to mount the ethernet panel mount connector. If I was smart I would have just soldered the 8 pin connector the the panel mount connector, but I had no desire to do any more soldering so I just worked with what I had laying around.

With that done, I buttoned it up, and I'm calling that part of it done!

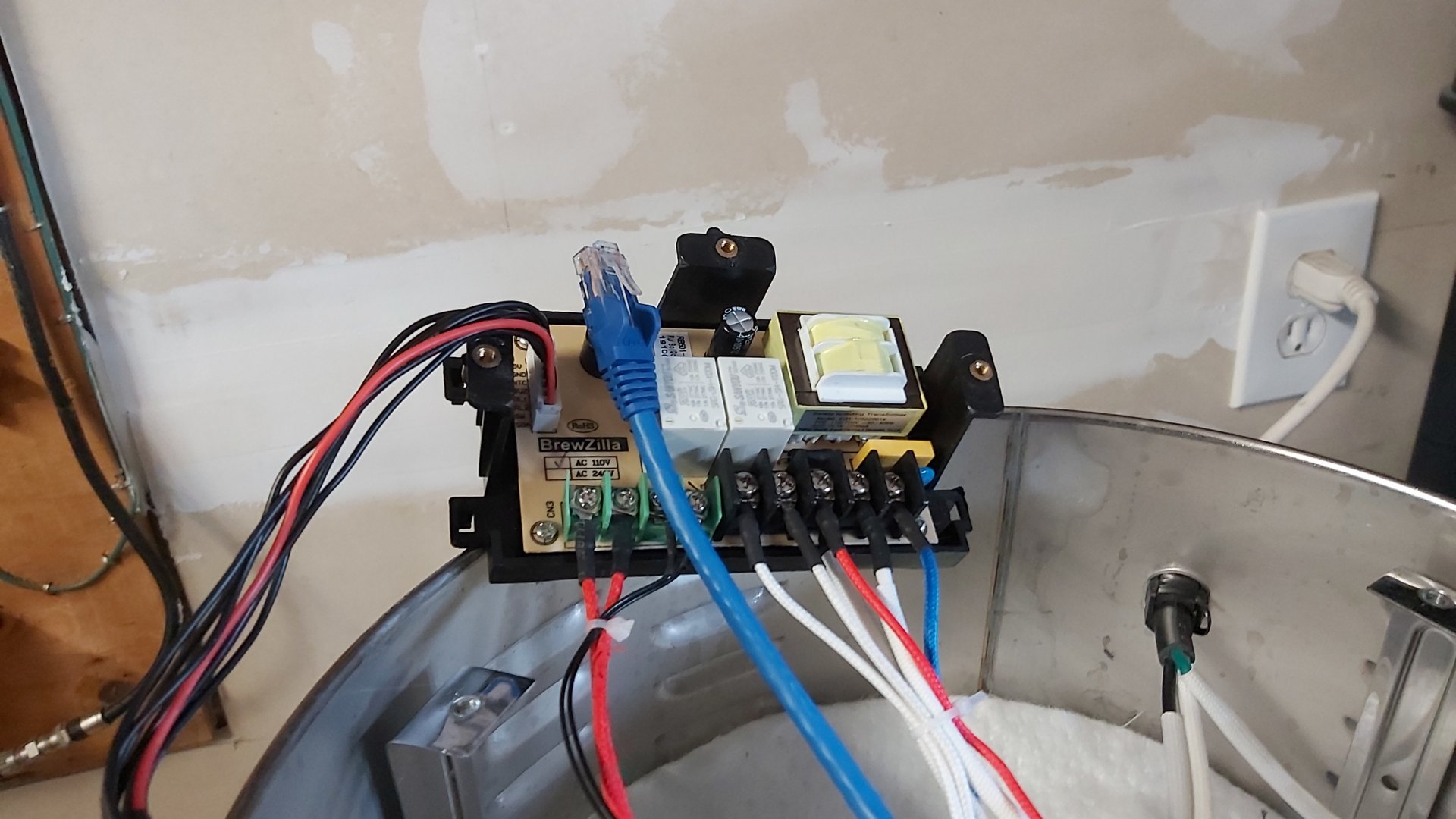

Now onto mounting the fill plate with the Cat5 bulkhead.

I struggled with how to mount this without butchering the machine for a while.

Ended up finding some super heavy duty two way foam tape. If I ever do need to remove it, that will be a bit of a b*tch, but very doable.

I had previously soldered up the patch cable to from the circuit board to the bulkhead on the inside of the filler plate.

Only thing I have left to tidy up is a weatherproof connector cover for the Cat5 cable end that connects to the machine.

I have it, just need to cut the cable, then splice back together.

Used two of the six screws to keep the two haves of the control module together, then used four longer screws to fasten the module to the lid of the panel box.

Cut a hole in the side of the panel box to mount the ethernet panel mount connector. If I was smart I would have just soldered the 8 pin connector the the panel mount connector, but I had no desire to do any more soldering so I just worked with what I had laying around.

With that done, I buttoned it up, and I'm calling that part of it done!

Now onto mounting the fill plate with the Cat5 bulkhead.

I struggled with how to mount this without butchering the machine for a while.

Ended up finding some super heavy duty two way foam tape. If I ever do need to remove it, that will be a bit of a b*tch, but very doable.

I had previously soldered up the patch cable to from the circuit board to the bulkhead on the inside of the filler plate.

- Joined

- Mar 14, 2018

- Messages

- 9,038

- Reaction score

- 16,412

- Points

- 113

I cut the filler plate from a piece of round galvanized steel ducting that I had on hand, it was pretty simple to get it to roughly match the radius of the machine. Stuffed the filler panel in there and gave the two way tape a real good squeeze, feels good and solid in there! Then connected the cat 5 cable on the inside.

Only thing left is to button up the bottom and see if I like how it turned out!

Only thing left is to button up the bottom and see if I like how it turned out!

- Joined

- Mar 14, 2018

- Messages

- 9,038

- Reaction score

- 16,412

- Points

- 113

I am very happy with how it turned out, now I can have this thing on the floor, and operate the controls from across the room if I like!

I may mount the controller somewhere convenient, or I may just use it like a pendant. I actually have a 50' long cat5 cable, so I could even run the cable up the wall, and have it drop down from the ceiling to connect to the panel at my card table. Eliminate any trip fall hazards you know!

I may mount the controller somewhere convenient, or I may just use it like a pendant. I actually have a 50' long cat5 cable, so I could even run the cable up the wall, and have it drop down from the ceiling to connect to the panel at my card table. Eliminate any trip fall hazards you know!

Mission accomplished. Nice work! Very impressive!!!

So the display and buttons are remote, but the controller and brains remain in the base?

That is, if I bought a spare display ($30) and made something into which to mount it (no plastic cover provided) I just need to get 8 wires from hither to yon?

That is, if I bought a spare display ($30) and made something into which to mount it (no plastic cover provided) I just need to get 8 wires from hither to yon?

- Joined

- Mar 14, 2018

- Messages

- 9,038

- Reaction score

- 16,412

- Points

- 113

Essentially, the smarts are in the display, it sends info to the circuit board. No need to purchase a second display.So the display and buttons are remote, but the controller and brains remain in the base?

That is, if I bought a spare display ($30) and made something into which to mount it (no plastic cover provided) I just need to get 8 wires from hither to yon?

Love your Work Man!

- Joined

- Mar 14, 2018

- Messages

- 9,038

- Reaction score

- 16,412

- Points

- 113

Thanks Brother!Love your Work Man!

Well, my goal is to leave the bz as is, and just add a second panel, using only one of them. For $30, worth it. To switch over, just unplug this one and plug in that one.

The Question would be how would you T into the line if the controller is already hooked up to it you'd have to switch from the mounted controller to your mobile one no?Well, my goal is to leave the bz as is, and just add a second panel, using only one of them. For $30, worth it. To switch over, just unplug this one and plug in that one.

- Joined

- Mar 14, 2018

- Messages

- 9,038

- Reaction score

- 16,412

- Points

- 113

To disconnect the existing panel, and connect to the external panel you would need to remove the bottom plate of the the BZ each time. Then there would be the wiring for the external panel, you would need to drill or cut a hole in the machine somewhere. This would likely void your warrantee. Here are the videos I found that inspired me to come up with this modular solution.Well, my goal is to leave the bz as is, and just add a second panel, using only one of them. For $30, worth it. To switch over, just unplug this one and plug in that one.

Cable Cutter, Noooooooooooo

Cable Cutter, but modular solution, still no

Smart PID Conversion, I gave this some serious consideration, but for the cost I may as well have bought the Grainfather in the first place!

You'd think so. My idea is to use two bulkhead connectors, one from the existing panel and one to the rest of the brewzilla. Connect the cat5 cable from the 'rest of' connector to either the internal or external panel.The Question would be how would you T into the line if the controller is already hooked up to it you'd have to switch from the mounted controller to your mobile one no?

Does that make sense?

Warranty schmarranty, I voided that the day after I got the thing...

Sorta sorta not lol. I'll leave it with the Brian's trustYou'd think so. My idea is to use two bulkhead connectors, one from the existing panel and one to the rest of the brewzilla. Connect the cat5 cable from the 'rest of' connector to either the internal or external panel.

Does that make sense?

Warranty schmarranty, I voided that the day after I got the thing...

- Joined

- Mar 14, 2018

- Messages

- 9,038

- Reaction score

- 16,412

- Points

- 113

And now there is this from Kegland...

Sometime last year I was messaging back and forth on a brewzilla users facebook page with a guy from kegland. I gave him a number of ideas some of which have been incorporated into the gen 4. I may just have to buy one of these along with some accessories like the steam condenser for instance! I could either semm my 3.1.1, or use it as an HLT for sparge water!

Sometime last year I was messaging back and forth on a brewzilla users facebook page with a guy from kegland. I gave him a number of ideas some of which have been incorporated into the gen 4. I may just have to buy one of these along with some accessories like the steam condenser for instance! I could either semm my 3.1.1, or use it as an HLT for sparge water!

- Joined

- Mar 31, 2021

- Messages

- 3,225

- Reaction score

- 5,116

- Points

- 113

Was an electronic tech for 15 years. Just remember, let the wire melt the solder. Don't overheat it, but make sure it flows. Grainy or lumpy jounts are cold and will failThese arrived yesterday

View attachment 16058

And this arrived today. I have never soldered wires before. I have soldered countless copper pipes, but no wires. Will have to do some sample connections before getting into it.

View attachment 16059

Edit: lol, didn't notice the date. I assume this has been fished for some time