You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Long Term Conditioning

- Thread starter AGbrewer

- Start date

- Joined

- Oct 19, 2017

- Messages

- 1,820

- Reaction score

- 2,388

- Points

- 113

For 12 months I'd leave plastic out because of the oxidation. I don't have room for barrels and don't brew enough for that to make sense. So that leaves me with glass and stainless. Stainless wins for me because of the closures being better at keeping oxygen out and it's easier to set up closed transfer if you need it. Also no risk of breaking.

In the stainless world corny kegs work well for me. I can use a spunding valve while fermentation is active and when it's not just leave it closed and pull the PRV every month or so. They're easy to set up for the transfer for blending or bottling and they don't take up much space.

In the stainless world corny kegs work well for me. I can use a spunding valve while fermentation is active and when it's not just leave it closed and pull the PRV every month or so. They're easy to set up for the transfer for blending or bottling and they don't take up much space.

- Joined

- Jul 25, 2018

- Messages

- 231

- Reaction score

- 217

- Points

- 43

I guess it depends on what you have room for and if you want batch conditioning or if smaller vessels are okay. Dito to Mark: I would not use plastic. I would use glass, stainless steel, or keg (wood or corny). UV light can effect flavor so if you use a glass carboy you should store it in away from sunlight.

I found a few 650 ml bottles that ended up in a dark cold corner in basement closet from a BGSA batch I brewed 2 years ago. The flavor was fabulously mellow.

I found a few 650 ml bottles that ended up in a dark cold corner in basement closet from a BGSA batch I brewed 2 years ago. The flavor was fabulously mellow.

I'm going to take a contrarian position and state that you can condition in plastic, glass, or stainless steel. I have used PET plastic bottles to condition for long-term and have not had any issues with oxidation. One reason is due to pressure. The yeast produce CO2 in the bottle. The bottle pressurizes. Atmospheric oxygen cannot get into a higher pressure vessel, particularly one that CO2 cannot escape from. Oxygen permeation of plastic is "brewing fact" that I have never seen confirmed by testing. My primary objection to plastic in storage and fermenting is scratching and creation of places for bacteria to hide. But oxygen cannot get into a vessel that CO2 cannot escape from.

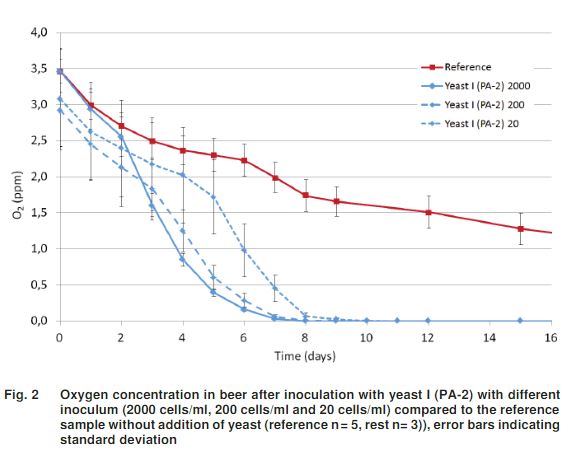

There are a few articles out there about oxygen scavenging by yeast. Yeast are pretty efficient at this. You can purge the head space with CO2, but that may not be a necessity. Take a look at the graph showing the effectiveness of live yeast scavenging oxygen. In eight days, the yeast scavenges all of the oxygen.

There are a few articles out there about oxygen scavenging by yeast. Yeast are pretty efficient at this. You can purge the head space with CO2, but that may not be a necessity. Take a look at the graph showing the effectiveness of live yeast scavenging oxygen. In eight days, the yeast scavenges all of the oxygen.

- Joined

- Jul 16, 2012

- Messages

- 10,254

- Reaction score

- 8,366

- Points

- 113

Another thing: It's possible for oxygen to diffuse through plastics under laboratory conditions. What's the actual rate of diffusion? How much O2 can I expect to diffuse through my PET bottle per square inch at our 0.8 atmospheres? I've never seen that data. Like Bubba, I have no fear whatsoever about long-term storage in plastic vessels and follow the logic: If gasses can diffuse through them at atmospheric pressure, they wouldn't hold carbonation. Or water, for that matter - the molecule is actually smaller than CO2 and less massive than O2.

Like Bubba, I believe that oxidation through plastic bottles is beer lore with little foundation in fact.

Like Bubba, I believe that oxidation through plastic bottles is beer lore with little foundation in fact.

- Joined

- Feb 2, 2015

- Messages

- 1,790

- Reaction score

- 2,881

- Points

- 113

I used to believe that if the container is pressurized with co2 that there would be no oxygen ingress. I have since found out that is not true, even the seals on glass bottle caps are susceptible to oxygen ingress. I can’t say I understand the mechanism, but oxygen can work it’s way into a pressurized vessel. Plastic bottles are much more susceptible to oxygen ingress. The problem not only exists in beer packaging, but also in water lines used for hot water heating. PEX pipe has an oxygen barrier that is required to prevent corrosion in the boiler due to oxygen ingress. If it were possible, the line could be pressurized to prevent this.But oxygen cannot get into a vessel that CO2 cannot escape from.

Not sure how serious of a problem it is for beer, but when was the last time you saw a high end craft beer like a RIS or Belgian Triple in a plastic bottle?

- Joined

- Oct 19, 2017

- Messages

- 1,820

- Reaction score

- 2,388

- Points

- 113

Hadn't thought about PET bottles. I keep thinking about bulk aging. I think the permeability of HDPE and barrels are around the same. The O2 permeability of PET is around 10 times lower than HDPE and the closures are good.

Some O2 transfer amounts for various container types in the table that's a little down the page - http://www.milkthefunk.com/wiki/Mixed_Fermentation#Aging

That said the beer might like some oxygen. So if barrel oxygenation levels work then HDPE storage wouldn't be that different as long as the closures are relatively good. And if there's brett in the mix it actually needs a bit of oxygen.

And most of my comments are based on 12 months aging. For anything you're willing to let sit for a few months, I don't think it'll be that important what you choose, more how good the closures are.

Some O2 transfer amounts for various container types in the table that's a little down the page - http://www.milkthefunk.com/wiki/Mixed_Fermentation#Aging

That said the beer might like some oxygen. So if barrel oxygenation levels work then HDPE storage wouldn't be that different as long as the closures are relatively good. And if there's brett in the mix it actually needs a bit of oxygen.

And most of my comments are based on 12 months aging. For anything you're willing to let sit for a few months, I don't think it'll be that important what you choose, more how good the closures are.

- Joined

- Feb 3, 2018

- Messages

- 3,798

- Reaction score

- 6,999

- Points

- 113

What is the best way to condition beer long term? I'm talking 1 year conditioning?

Why do you believe that it is the best way?

Most anything I would consider conditioning for a year would be bottled. Once given a reasonable time and temperature for natural carbonation, I'd store as close to 50F as possible. Personally, I can't think of anything I'd keg and condition for that long. but that's just me.

As for reasoning, it's a matter of preference and how I've done the few beers I felt would benefit from aging with success. This is one of those questions that you can ask 20 brewers and expect that many answers.

- Joined

- Feb 3, 2018

- Messages

- 3,798

- Reaction score

- 6,999

- Points

- 113

I'm going to take a contrarian position and state that you can condition in plastic, glass, or stainless steel. I have used PET plastic bottles to condition for long-term and have not had any issues with oxidation. One reason is due to pressure. The yeast produce CO2 in the bottle. The bottle pressurizes. Atmospheric oxygen cannot get into a higher pressure vessel, particularly one that CO2 cannot escape from. Oxygen permeation of plastic is "brewing fact" that I have never seen confirmed by testing. My primary objection to plastic in storage and fermenting is scratching and creation of places for bacteria to hide. But oxygen cannot get into a vessel that CO2 cannot escape from.

There are a few articles out there about oxygen scavenging by yeast. Yeast are pretty efficient at this. You can purge the head space with CO2, but that may not be a necessity. Take a look at the graph showing the effectiveness of live yeast scavenging oxygen. In eight days, the yeast scavenges all of the oxygen.

View attachment 10289

I'm with you here. I've read that atmospheric O2 can enter sealed and pressurized containers. I've yet to see any compelling evidence of this. It flies in the face of everything I learned and practiced in the many years I worked with HVAC. One of the constants of pressure is that any flow of matter will be from the high to the low. There are chemical, and other non pressure related, reactions that may cause exchange, but not in a volume significant enough to affect a beer stored for a reasonable period of time.

- Joined

- Apr 14, 2019

- Messages

- 382

- Reaction score

- 985

- Points

- 93

Another thing to consider is whether you want something you’re going to ingest in contact with plastic for that long a period of time. Although PET and HDPE are considered “safer” plastics, none are actually safe and there is the potential for chemical compounds to leach into whatever is being contained. Therefore, I would consider glass or SS.

- Joined

- Oct 19, 2017

- Messages

- 1,820

- Reaction score

- 2,388

- Points

- 113

I suppose I've been assuming bulk aging under no pressure. While I think the original question was more to do with storing individual bottles that start out with a conditioning phase.I'm with you here. I've read that atmospheric O2 can enter sealed and pressurized containers. I've yet to see any compelling evidence of this. It flies in the face of everything I learned and practiced in the many years I worked with HVAC. One of the constants of pressure is that any flow of matter will be from the high to the low. There are chemical, and other non pressure related, reactions that may cause exchange, but not in a volume significant enough to affect a beer stored for a reasonable period of time.

- Joined

- Feb 3, 2018

- Messages

- 3,798

- Reaction score

- 6,999

- Points

- 113

I suppose I've been assuming bulk aging under no pressure. While I think the original question was more to do with storing individual bottles that start out with a conditioning phase.

And you make a good case for bulk aging. I just assumed long term storage of packaged product.

- Joined

- Jul 25, 2018

- Messages

- 231

- Reaction score

- 217

- Points

- 43

Wow. Lots of great information here that I never thought of. Although the stand out comment is "I have never seen a commercial brew, macro or micro, in plastic." Having not done the actual scientific research and experiments I would deduce there is probably a good reason for not using plastic bottles. There is a good reason for using corks with a wire cage in heavy bottles as well. I used to think it was just to make the bottle fancy, now as a brewer I would deduce the reason is so you can make a brew high carb. and need the extra think bottle which does not normally fit normal bottle caps...but I digress! Frankly, for aging I would defer to the deductions I can make from more experienced macro/micro/traditional brewers.

The original question was:

What is the best way to condition beer long term? I'm talking 1 year conditioning?

Why do you believe that it is the best way?

O2 ingress aside, if it was me with my current set up and equipment (aging a braggot or barley wine or tripel), I'd use brown glass (brown to ward off UV light which can skunk a beer) 650 ml bomber bottle (which is easy to come by) with a regular cap (I have hundreds and they are easy to use) stashed away in a basement closet (its a nice temperature stable place out of the way and is dark and cool but not cold) is good enough for me.

If I had a corny I'd use that to do bulk aging.

If I wanted really fancy I'd age in a brown glass bottles and after capping, dip the cap and neck up to about 1 inch in sealing wax for a little extra protection.

Some of the aged stuff (foreign Belgian beers mostly) that I HAVE seen is in a brown glass bottle with the little extra step to dip the end of the bottle and the cap in sealing wax and all wrapped in paper bag (I'd guess to protect against UV AND make it pretty).

The original question was:

What is the best way to condition beer long term? I'm talking 1 year conditioning?

Why do you believe that it is the best way?

O2 ingress aside, if it was me with my current set up and equipment (aging a braggot or barley wine or tripel), I'd use brown glass (brown to ward off UV light which can skunk a beer) 650 ml bomber bottle (which is easy to come by) with a regular cap (I have hundreds and they are easy to use) stashed away in a basement closet (its a nice temperature stable place out of the way and is dark and cool but not cold) is good enough for me.

If I had a corny I'd use that to do bulk aging.

If I wanted really fancy I'd age in a brown glass bottles and after capping, dip the cap and neck up to about 1 inch in sealing wax for a little extra protection.

Some of the aged stuff (foreign Belgian beers mostly) that I HAVE seen is in a brown glass bottle with the little extra step to dip the end of the bottle and the cap in sealing wax and all wrapped in paper bag (I'd guess to protect against UV AND make it pretty).

- Joined

- Mar 12, 2017

- Messages

- 2,493

- Reaction score

- 5,169

- Points

- 113

From all the excellent answers here I think what you use really comes down to two questions.

1) What do you have available?

2) What are you comfortable with?

I bulk age my wee heavy and w00t stout (4-6 months) in a glass fermenter because...

1) I have a glass fermenter available that I can tie up for that long and

2) I feel more comfortable with glass over plastic for bulk aging.

After bulk aging, I bottle and let it condition for another 6-12 months.

Another piece of advice I'll give on extended conditioning has proponents on both sides. That is whether to add yeast when bottling. I say yes because the one time I didn't, most of the bottles were severely under-carbonated over a year later. Apparently after five months of bulk aging there just wasn't enough yeast left to carbonate. The ABV was around 9% so it was within the alcohol tolerance of the yeast.

1) What do you have available?

2) What are you comfortable with?

I bulk age my wee heavy and w00t stout (4-6 months) in a glass fermenter because...

1) I have a glass fermenter available that I can tie up for that long and

2) I feel more comfortable with glass over plastic for bulk aging.

After bulk aging, I bottle and let it condition for another 6-12 months.

Another piece of advice I'll give on extended conditioning has proponents on both sides. That is whether to add yeast when bottling. I say yes because the one time I didn't, most of the bottles were severely under-carbonated over a year later. Apparently after five months of bulk aging there just wasn't enough yeast left to carbonate. The ABV was around 9% so it was within the alcohol tolerance of the yeast.

I have not tried bulk aging for that length of time. I don't age too many beers, but when I do, I bottle (and add priming sugar) prior to aging.I bulk age my wee heavy and w00t stout (4-6 months) in a glass fermenter

After bulk aging, I bottle and let it condition for another 6-12 months.

What do you see as the advantage of bulk aging vs. bottle aging?

- Joined

- Oct 19, 2018

- Messages

- 473

- Reaction score

- 358

- Points

- 63

I suppose I've been assuming bulk aging under no pressure. While I think the original question was more to do with storing individual bottles that start out with a conditioning phase.

Most of the beers I make are between 1.090 and 1.165 OG. So what I was really looking for (and probably did a poor job of communicating it) was long term bulk conditioning in a vessel. Reason being is that I don't have a ton of space to put 10 cases of beer. But I could easily hide 5 kegs in a closet that is temp controlled (albeit only to about 70 degrees). Or even in the fermentation freezer depending on how many fermentation kegs I've got.

The short of it is that I've decided to do a test run with kegs for long term bulk conditioning. Got one right now that has been in the keg for almost 2 months and I didn't pressurize it. It has some whiskey chips in it as well. It might get some oxidation, but this is more of a test for me than anything to see how bad it really will be. Once I bottle it, I'll let you know how it tastes. Should be drinking it around December of this year.

- Joined

- Mar 12, 2017

- Messages

- 2,493

- Reaction score

- 5,169

- Points

- 113

What do you see as the advantage of bulk aging vs. bottle aging?

To be honest, I don't really have a definitive reason I can point to. I pretty much picked it up from the forums and other online sources. If it's on the internet it has to be true, right?

- Joined

- Oct 19, 2017

- Messages

- 1,820

- Reaction score

- 2,388

- Points

- 113

For me the bulk aging is for the mixed ferments or the imperials. For the mixed ferments it's to let the non-sacch microbes change the beer. For the imperials I'll keg condition 6 litres in a small keg and bottle the rest. That's purely so I can have it on tap and I can't get through more than 6 litres without it tying up a tap forever.

I'm finding that most of the imperials start improving after about 3 months and I'm really enjoying them at 6 months. Around 12 months they can start falling apart if I don't have control of the O2 during packaging (which is less of a problem now with changes to the process).

For the mixed ferments they start improving at 6 months and can last much longer, but mine have all been gone by about 12 months. This is the one where I'm focusing on bulk aging versus bottle aging. The brett needs a container that's going to cope with the pressure changes through seasons and the slow constant production of CO2 all while keeping the O2 under control. It's all slow going and once I've got a few more years I'll hopefully be able to tell whether it matters whether it's bulk or bottle. And even it if doesn't matter much, storing all the sours I want to make in cornies is going to take up so much less space than bottles.

I'm finding that most of the imperials start improving after about 3 months and I'm really enjoying them at 6 months. Around 12 months they can start falling apart if I don't have control of the O2 during packaging (which is less of a problem now with changes to the process).

For the mixed ferments they start improving at 6 months and can last much longer, but mine have all been gone by about 12 months. This is the one where I'm focusing on bulk aging versus bottle aging. The brett needs a container that's going to cope with the pressure changes through seasons and the slow constant production of CO2 all while keeping the O2 under control. It's all slow going and once I've got a few more years I'll hopefully be able to tell whether it matters whether it's bulk or bottle. And even it if doesn't matter much, storing all the sours I want to make in cornies is going to take up so much less space than bottles.