- Joined

- May 12, 2018

- Messages

- 814

- Reaction score

- 825

- Points

- 93

So I got my Chico tap water report from Ward

pH - 7.8

Cations - 2.9

Anions - 2.9

Sodium - 12

Magnesium - 14

Total Hardness, CaCo3 - 113

Sulfate, So4-S - 1

Bicarbonate, HCO3 - 156

Total Alkalinity, CaCO3 - 129

I downloaded the Brun Water spreadsheet. I have actually tried several but this one seems the most comprehensive. I also tried the BF calculator. Not settled on one yet. I'm trying to figure out how the BF calculator relates to a recipe . . . I can't figure out the pH and why it doesn't agree with the Brun Water calculator and to be honest with all the complaints I'm not sure I want to until things settle...

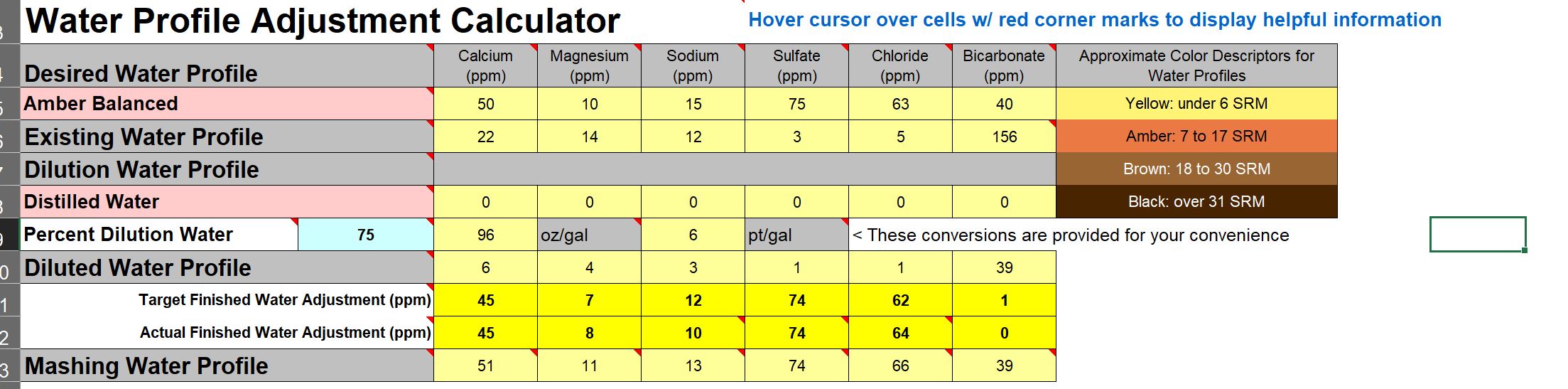

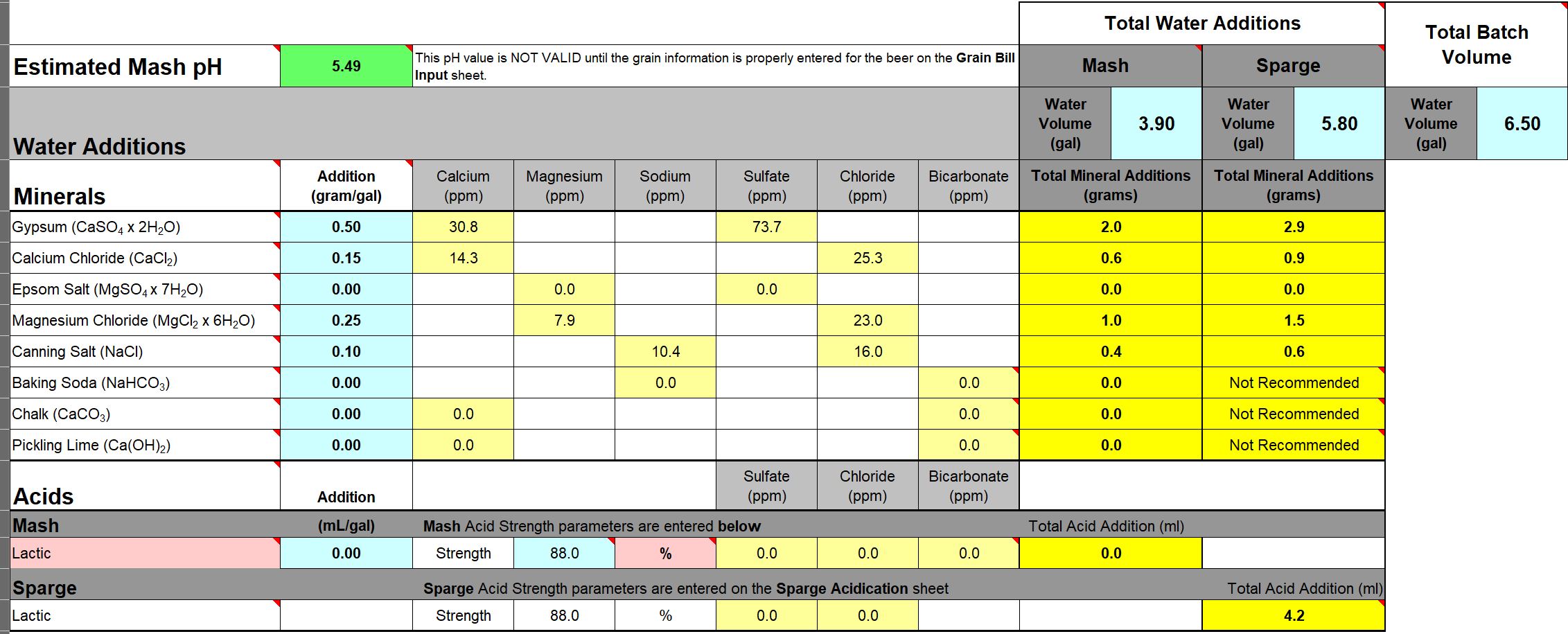

Right now I'm working on my Pale Ale and an "Amber Balanced" target per the Brun Water calculator

I'm guessing "balanced" means balanced SO4/Cl?

To get my HCO3 to 40 I found I need to dilute with DI water at 75% DI 25% tap and add salts (see below)

The calculator gives two kinds of water - Mash and Sparge

Process question - Do I add salts directly to the mash or to the water before the mash?

Target question - does the target look like a good one for a West Coast American Pale Ale?

I'm going to try this on my next House Pale Ale

I can't get the pH to align with the Brun Water calculator and I DKW but I'm not in the mood to struggle with it with the state of the site

pH - 7.8

Cations - 2.9

Anions - 2.9

Sodium - 12

Potassium - 2

Calcium - 22Magnesium - 14

Total Hardness, CaCo3 - 113

Sulfate, So4-S - 1

Chloride - 5

Carbonate, CO3 < 1.0Bicarbonate, HCO3 - 156

Total Alkalinity, CaCO3 - 129

I downloaded the Brun Water spreadsheet. I have actually tried several but this one seems the most comprehensive. I also tried the BF calculator. Not settled on one yet. I'm trying to figure out how the BF calculator relates to a recipe . . . I can't figure out the pH and why it doesn't agree with the Brun Water calculator and to be honest with all the complaints I'm not sure I want to until things settle...

Right now I'm working on my Pale Ale and an "Amber Balanced" target per the Brun Water calculator

I'm guessing "balanced" means balanced SO4/Cl?

To get my HCO3 to 40 I found I need to dilute with DI water at 75% DI 25% tap and add salts (see below)

The calculator gives two kinds of water - Mash and Sparge

Process question - Do I add salts directly to the mash or to the water before the mash?

Target question - does the target look like a good one for a West Coast American Pale Ale?

I'm going to try this on my next House Pale Ale

I can't get the pH to align with the Brun Water calculator and I DKW but I'm not in the mood to struggle with it with the state of the site

Last edited: