Gday brewers.

To outline objectives here.

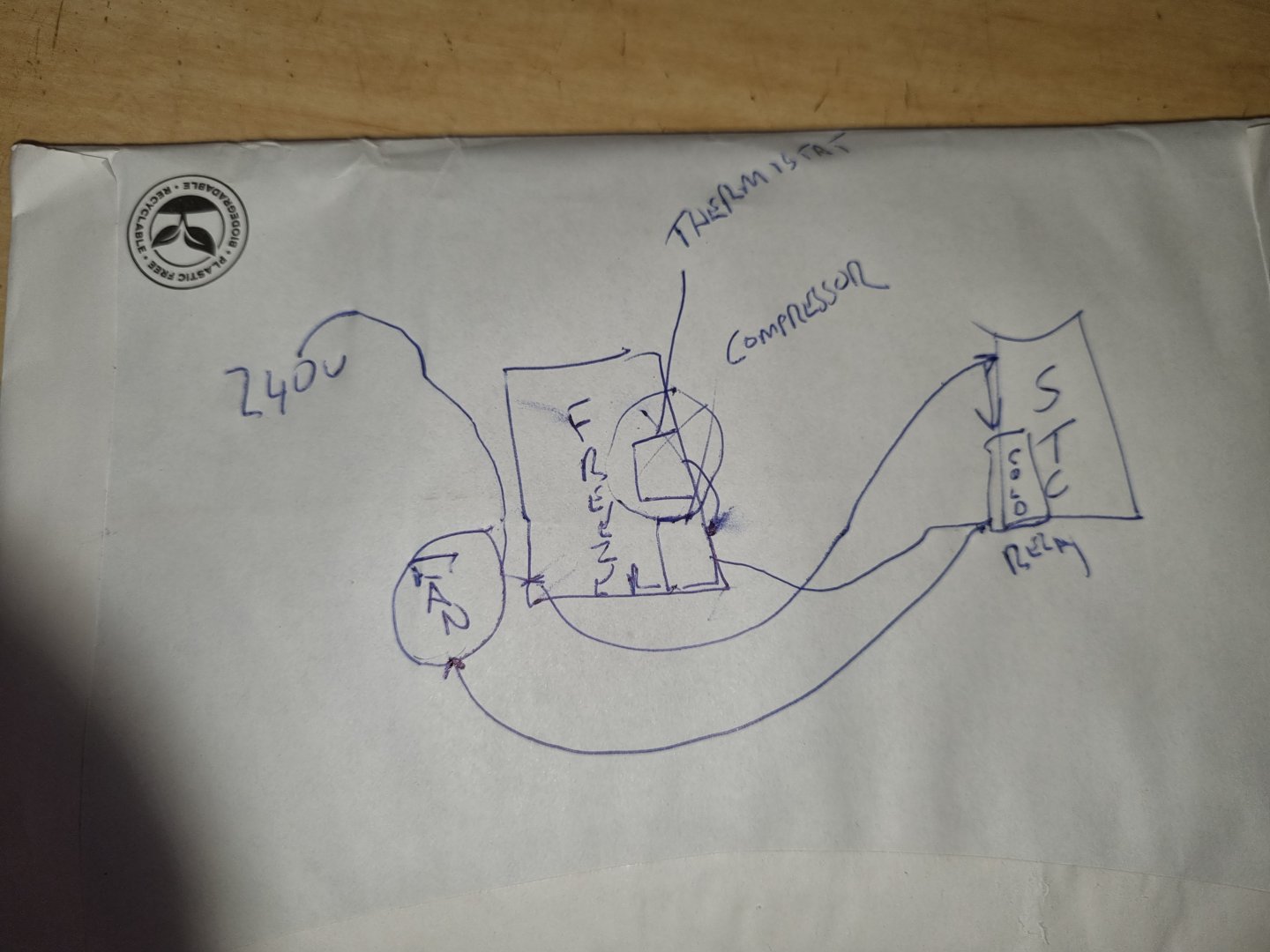

Hopefully bypass chest freezers thermostat with STC1000 thermostat.

As is I'm using a stc1000 inline with freezers thermostat to switch on compressor.

Power into freezer then power bypass up into Stc1000 in cabinet to cold relay which returns to power freezer.

I've got the freezer thermostat set as cold as it goes so in theory the -5c that the stc is controlling should switch without any issues.

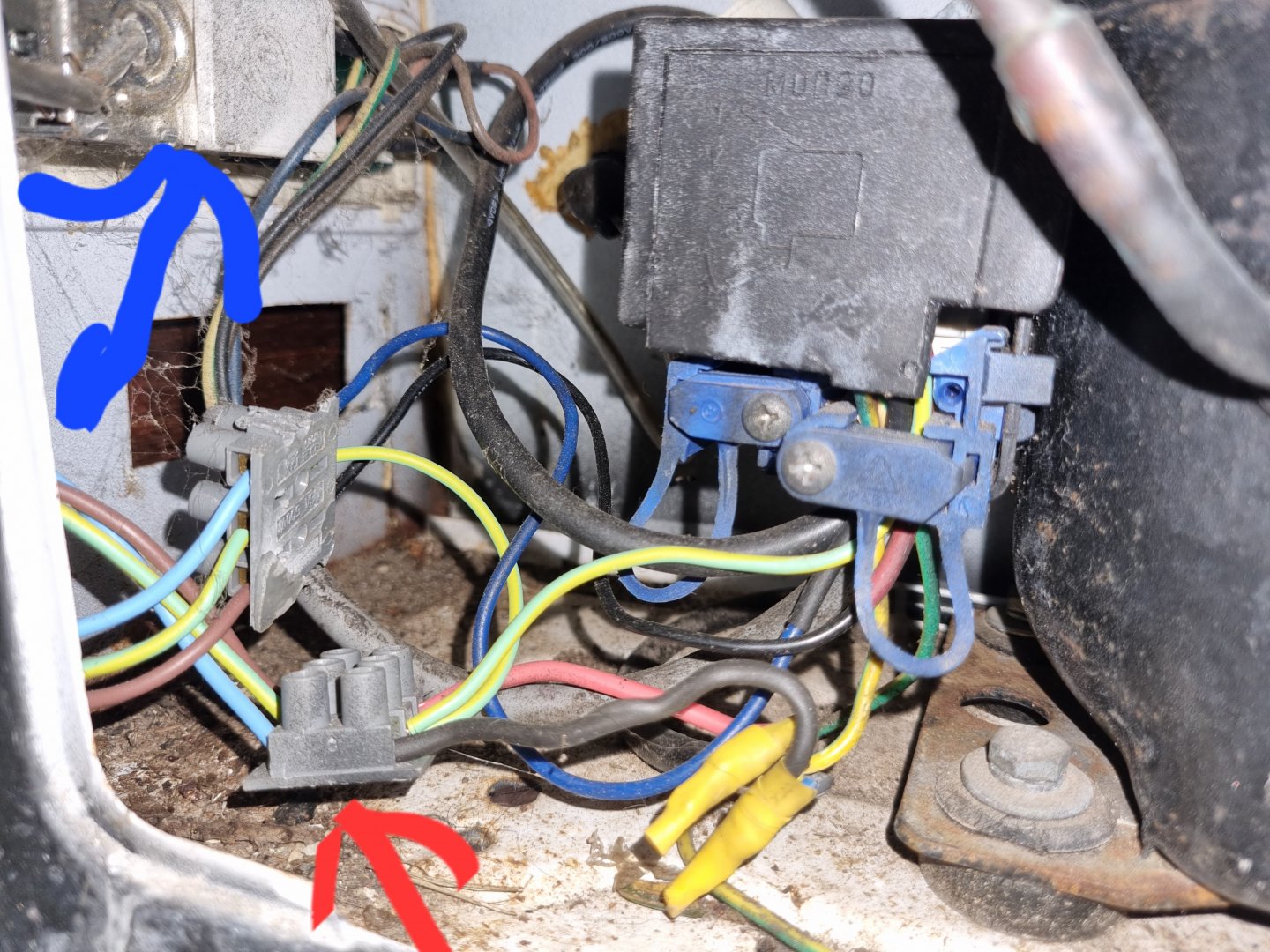

This is by bypass wire hooked into that black box top right

Freezers thermostat is blue arrow.

I've had the freezer for atleast 5 years and have run it like this the whole time

Recently I found the stc cold relay would be on but the freezer wouldn't be running (seemed to me like it's thermostat was switched off preventing the compressor from.l firing

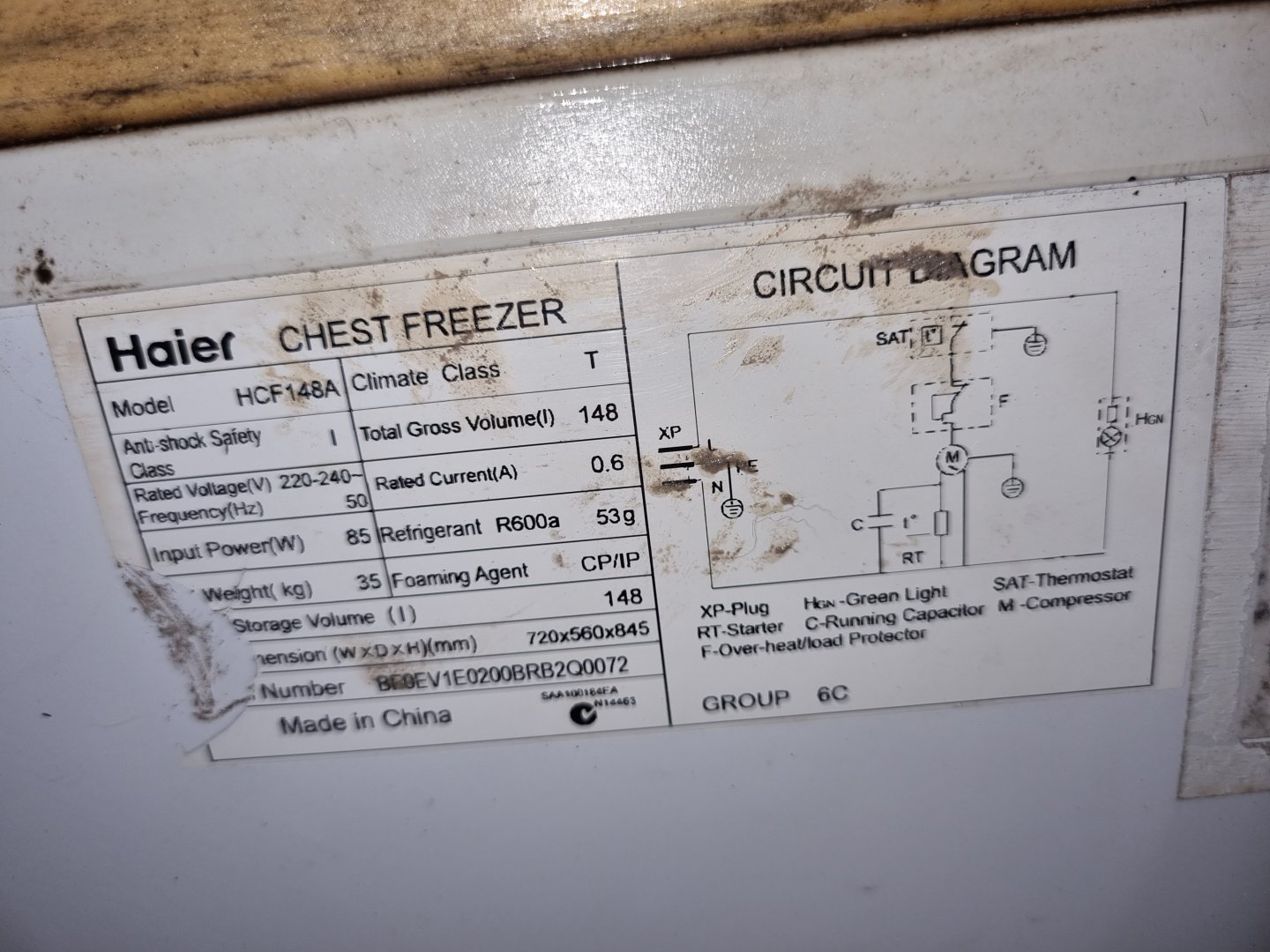

This is the freezer specs

Looks like it's playing game this morning lol but still to unreliable.

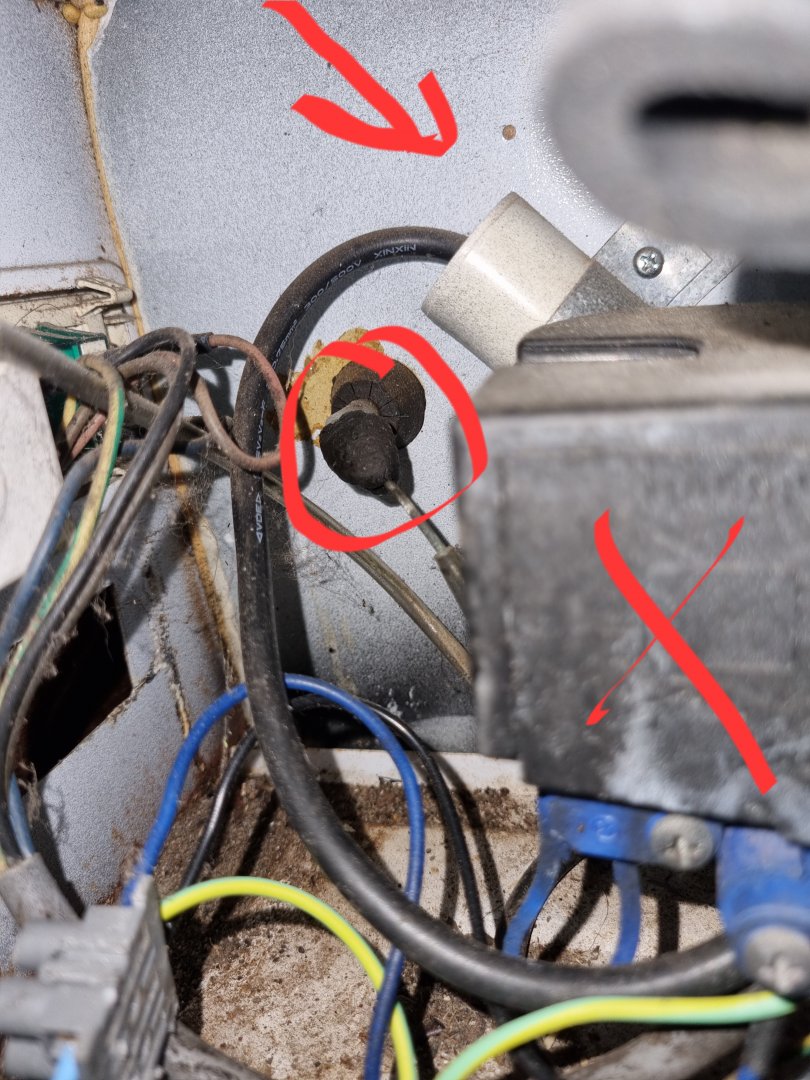

That's the temp sensor or (thermistor?)

That black box us sorta the wiring Junction

I just gotta figure out where them wires go so I can wire them via the STC cold relay wires instead

That capacitor is probably for the compressor motor?

Anyhow I think this may have confused you more it's hard to see from just pictures

Another option is forgoing the STC all together now that I've added more glycol to the chamber it shouldn't freeze if I just use it own controller but I think bottom line it's playing up.

What do you rekon ?

If I get a new freezer it's 500$ ish I'd need to match the dimentions because of my cabinet build lol.

Anyhow enough rambling.

To outline objectives here.

Hopefully bypass chest freezers thermostat with STC1000 thermostat.

As is I'm using a stc1000 inline with freezers thermostat to switch on compressor.

Power into freezer then power bypass up into Stc1000 in cabinet to cold relay which returns to power freezer.

I've got the freezer thermostat set as cold as it goes so in theory the -5c that the stc is controlling should switch without any issues.

This is by bypass wire hooked into that black box top right

Freezers thermostat is blue arrow.

I've had the freezer for atleast 5 years and have run it like this the whole time

Recently I found the stc cold relay would be on but the freezer wouldn't be running (seemed to me like it's thermostat was switched off preventing the compressor from.l firing

This is the freezer specs

Looks like it's playing game this morning lol but still to unreliable.

That's the temp sensor or (thermistor?)

That black box us sorta the wiring Junction

I just gotta figure out where them wires go so I can wire them via the STC cold relay wires instead

That capacitor is probably for the compressor motor?

Anyhow I think this may have confused you more it's hard to see from just pictures

Another option is forgoing the STC all together now that I've added more glycol to the chamber it shouldn't freeze if I just use it own controller but I think bottom line it's playing up.

What do you rekon ?

If I get a new freezer it's 500$ ish I'd need to match the dimentions because of my cabinet build lol.

Anyhow enough rambling.