- Joined

- Mar 31, 2021

- Messages

- 4,327

- Reaction score

- 6,426

- Points

- 113

Havent seen alot of information on these, but it just looks too cool not to get one. ordered it 3 days ago and it will be here tommorow! talk about service! 5 days from Italy.

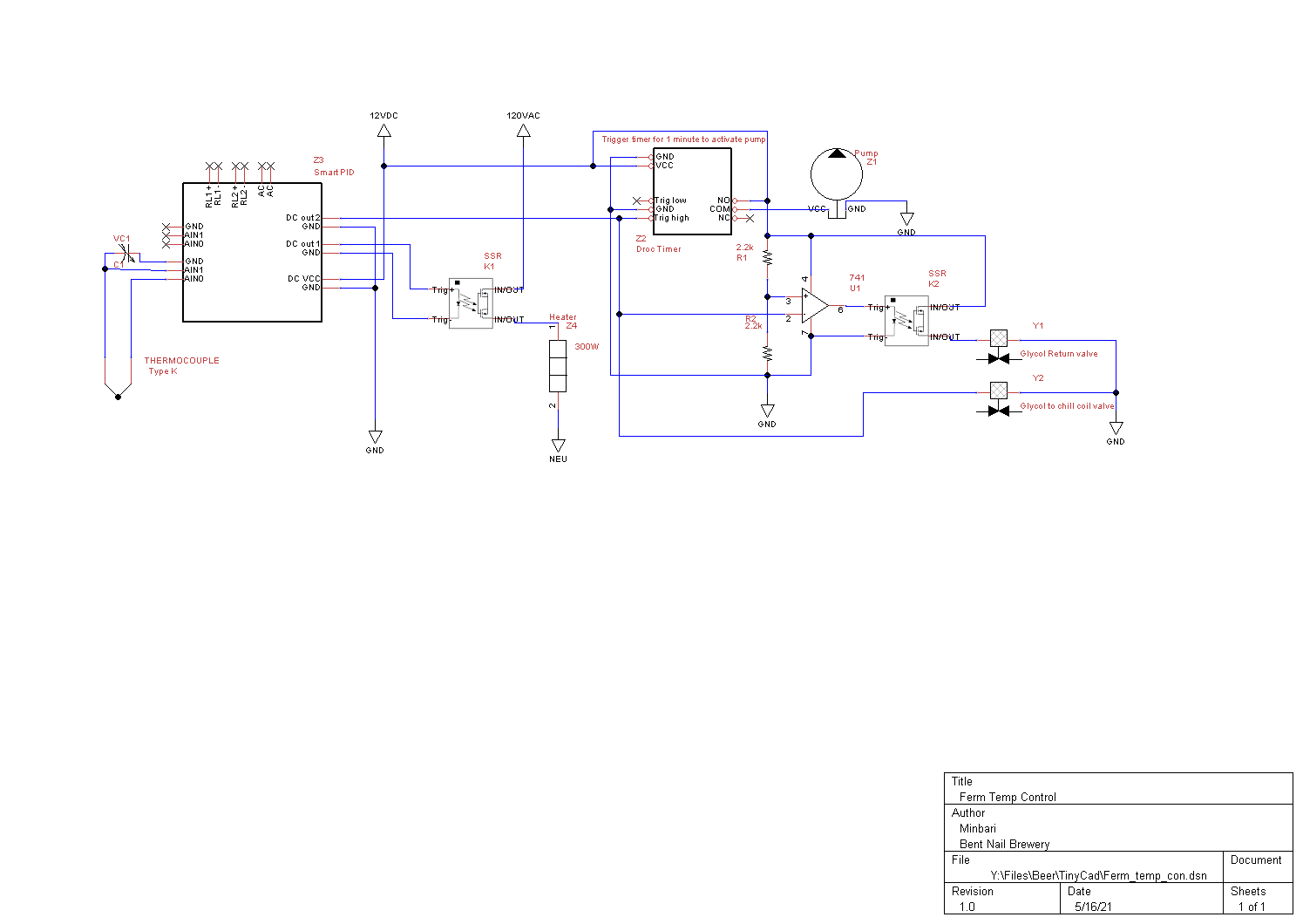

here is how I plan to implement it.

there are 2 PID controllers in the Smart PID module.

#1 will control the heating element with PID controlled PWM.

#2 will control the glycol chilling also with PID controlled PWM. The timer module will trigger off the PWM output to activate the pump. The PWM from the PID controler will drive a pair of solenoid valves to direct the glycol mixture either back to the reservoir or into the chiller coil in the fermenter. the Pump will shut off after the temp is reached and the PID output stops.

here is how I plan to implement it.

there are 2 PID controllers in the Smart PID module.

#1 will control the heating element with PID controlled PWM.

#2 will control the glycol chilling also with PID controlled PWM. The timer module will trigger off the PWM output to activate the pump. The PWM from the PID controler will drive a pair of solenoid valves to direct the glycol mixture either back to the reservoir or into the chiller coil in the fermenter. the Pump will shut off after the temp is reached and the PID output stops.