Hi Folks, first time poster, sorry if this is in the wrong place.

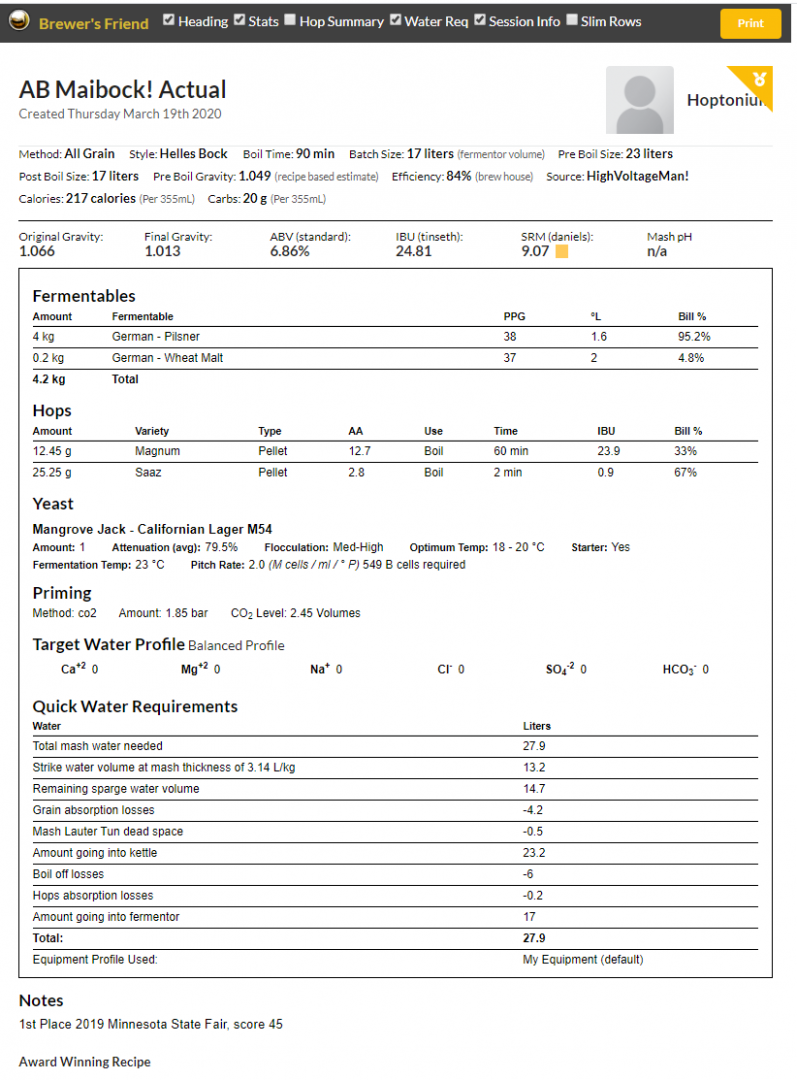

I copied a Maibock recipe from HighVoltageMan! and totally missed on the OG.

My measured OG was 1.042, which will result in a pathetic ABV of 3.81% if the rest of the brew goes to plan. I am also worried that I'm going to be missing a lot of flavor

This was the first time I tried to use a cooler based mash tun so I'm thinking I may have done something wrong. This was my mash plan:

Another possibility for the low OG reading: I use a standard hydrometer and measured the OG after pouring the cooled wort from the kettle into the fermenting bucket. I am wondering if the vigorous churn from the pouring temporarily causes the wort density to decrease because of the "trapped" air...? By measuring after pouring my reading was off...?

In any case, I will measure the density today after 24 hours of sitting in the fermenter to see if my alternate theory is correct. Otherwise, a couple of questions:

Anthony

I copied a Maibock recipe from HighVoltageMan! and totally missed on the OG.

My measured OG was 1.042, which will result in a pathetic ABV of 3.81% if the rest of the brew goes to plan. I am also worried that I'm going to be missing a lot of flavor

This was the first time I tried to use a cooler based mash tun so I'm thinking I may have done something wrong. This was my mash plan:

- Strike water, 13.2 L at 70C, added all grains, temperature dropped to 63C. Put the lid on.

- Checked the temp at 15 minutes, it was 62.7C. My mashtun loses about 1 C/hr.

- Steeped for 60 minutes and drained.

- Sparged with 14.7 L at 75C, twice - I didn't let the sparge sit long, maybe 5 minutes - maybe that was the problem...?

Another possibility for the low OG reading: I use a standard hydrometer and measured the OG after pouring the cooled wort from the kettle into the fermenting bucket. I am wondering if the vigorous churn from the pouring temporarily causes the wort density to decrease because of the "trapped" air...? By measuring after pouring my reading was off...?

In any case, I will measure the density today after 24 hours of sitting in the fermenter to see if my alternate theory is correct. Otherwise, a couple of questions:

- Did I miss, or botch, a step in the mashing?

- Can I recover the brew by adding some extract? If so, can you step me through that process?

Anthony

Last edited: