I apologize if this question has been asked before, as I’m sure it has. And from my experience in other forums I know it is poor etiquette to ask a common question without researching previous threads/forums for the answer before you ask it. However, I did search but kept coming up with “no search results” each time. My question is simply “Do I need to add a certain amount of acid to my mash water prior to adding the grain in order to ensure I get to the magic pH of 5.2?” I use either RO water and/or distilled water, adding brewing salts to distilled water to build a profile, and doing minimal additions to RO water as the label on the 5 gallon bottle clearly states that minerals have been added “for taste”. I have searched Google as well, but can’t seem to find a clear answer that makes sense.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yet another stupid question…

- Thread starter MrStacy

- Start date

- Joined

- Mar 12, 2017

- Messages

- 2,735

- Reaction score

- 5,697

- Points

- 113

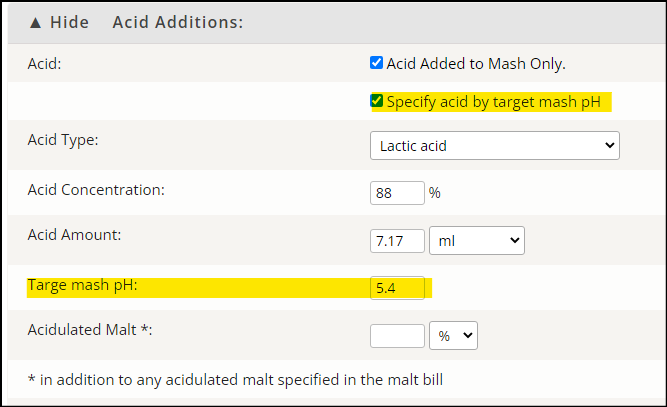

Fortunately, we aren't like other web sites. Plus the search feature on this site is rather poor. I use filtered tap water and have a report from my local water department, so I know what I am starting with. I plug that into the water profile. When editing a recipe I use the water calculator and specify my desired pH target and the acid I am using. The calculator will spit out the how much acid to add.

Since you're starting with RO or distilled water, I doubt you'll have to add much.

Since you're starting with RO or distilled water, I doubt you'll have to add much.

- Joined

- Mar 31, 2021

- Messages

- 4,321

- Reaction score

- 6,416

- Points

- 113

The search function on this site is tricky.

I use "ezwater" spreadsheet. You can search online for it. It will give you the amount of acid to use if your grain doesn't provide enough.

I usually go a little light on the acid at first. You can always add more. Just do a ph test in the first 5 minutes or so after dough in and adjust as needed

I use "ezwater" spreadsheet. You can search online for it. It will give you the amount of acid to use if your grain doesn't provide enough.

I usually go a little light on the acid at first. You can always add more. Just do a ph test in the first 5 minutes or so after dough in and adjust as needed

The Search function here has its challenges.I apologize if this question has been asked before, as I’m sure it has. And from my experience in other forums I know it is poor etiquette to ask a common question without researching previous threads/forums for the answer before you ask it. However, I did search but kept coming up with “no search results” each time. My question is simply “Do I need to add a certain amount of acid to my mash water prior to adding the grain in order to ensure I get to the magic pH of 5.2?” I use either RO water and/or distilled water, adding brewing salts to distilled water to build a profile, and doing minimal additions to RO water as the label on the 5 gallon bottle clearly states that minerals have been added “for taste”. I have searched Google as well, but can’t seem to find a clear answer that makes sense.

The clear and definite answer is 'maybe'.

What I do is build the recipe (carefully) in the recipe section (ask if you need guidance), then use the Water Calculator link near the bottom right to figure out what salts I need to add (chloride, calcium, sulphate,. etc). On that same calculator is, as Aharper notes, a section for acids. If the pH is close enough to 5.2 (waaay at the bottom there is a pH display with maybe a green check, yellow something or red X - I look for the green) I'm done, if it is a lot too high, I add up to 3 ml of acid, to both mash and sparge waters (8 gallons total, 5 gallon batch). If I need more than that, I use acidulated malt (one of my recipes needs 1/4 lb).

We've definitely had this question before, and the usual conclusion is "don't worry about it, you will still get beer" even if you do nothing.

- Joined

- Jun 27, 2019

- Messages

- 2,801

- Reaction score

- 8,566

- Points

- 113

In my opinion, there is no magic pH. More like a range of 5.2-5.8, or more narrowly 5.3-5.5. pH is a pretty deep topic and there are reasons why you might want to be at one value or another, but my points are 1) 5.2 is riding the bottom of the range and 2) you have plenty of wiggle room.the magic pH of 5.2?

- Joined

- Feb 2, 2015

- Messages

- 1,865

- Reaction score

- 3,070

- Points

- 113

Exactly. I aim for a pH of 5.6 in the mash (it increases extraction efficiency). Keep in mind that pH is measured at room temperature with a meter, not at mash temperatures. The strips are more of a best guess and can be used directly in the hot mash. But as Megary pointed out, it's more of range of pH than an exact number.In my opinion, there is no magic pH. More like a range of 5.2-5.8, or more narrowly 5.3-5.5. pH is a pretty deep topic and there are reasons why you might want to be at one value or another, but my points are 1) 5.2 is riding the bottom of the range and 2) you have plenty of wiggle room.

As the mash is heated the pH will drop about .2-.3 points. So a mash pH measured with a meter at room temperature of 5.4, will be @ 5.2 at mash temperatures. pH strips aren't as accurate or sensitive, so the whole "range" idea comes into play.

Do you need acid in the strike water? As Donoroto pointed out, maybe. The mash pH is set up by the water and grain. If you water is alkaline, that will push the pH up. You could add acid to counter this or switch to RO water. The color can have an effect as well. The darker malts contain more acids than lighter malts and pH will be lower with darker malts, this can be countered with alkaline water. The water calculators can help a lot this.

Often brewers will keep an eye on their mash pH and once it's done they don't monitor it anymore. That number of 5.2 pH is really important at pitching. This will set the yeast and the beer up for good finish pH of the beer. Finish pH's range from 3.9 to 4.5. So I check the preboil and post-boil pH and adjust accordingly, but I'm an anal retentive control freak.

Hopefully I didn't confuse or discourage you.

- Joined

- May 8, 2022

- Messages

- 58

- Reaction score

- 81

- Points

- 18

There are no stupid questions, only stupid forums.

- Joined

- Mar 14, 2018

- Messages

- 11,133

- Reaction score

- 20,884

- Points

- 113

I actually use Brewfather as my brewing software, and find the calculators there for water very intuitive (once you understand how it works). There are a lit of factors, the very least of which is the beginning ph of your water. One of the biggest factor in mash ph is the make up of your grist. Lighter colored brews will either need some acid, or some acidulated malt. Darker beers will usually need some baking soda.

Edit: I am a paid subscriber here, so I don't apologize for using other software. I am here for the great community that we have her at BF!

Edit: I am a paid subscriber here, so I don't apologize for using other software. I am here for the great community that we have her at BF!

Yep this place is a “community” besides every time a question gets asked or asked again I learn something. I only check other forums to see what I can learn. I feel like the people on here are friends not internet posters.

Last edited:

- Joined

- Jul 4, 2022

- Messages

- 3,137

- Reaction score

- 5,226

- Points

- 113

I am probably way on the simple side. If I am making a normal recipe at my level, I use Florida, bottled spring water, and it has always been drinkable not worrying about PH. If I were making a living from brewing, it would be different.

- Joined

- Jan 27, 2019

- Messages

- 5,102

- Reaction score

- 11,729

- Points

- 113

I use my tap water without other additions.

It's actually straight river water, but of good quality.

I've used strips and am somewhere between 5.5 and 6.0. Maybe I should use some acid, but I'm happy with my beers so I've pushed that to the future (one day I'll go back there )

)

It's actually straight river water, but of good quality.

I've used strips and am somewhere between 5.5 and 6.0. Maybe I should use some acid, but I'm happy with my beers so I've pushed that to the future (one day I'll go back there

- Joined

- Aug 19, 2012

- Messages

- 2,906

- Reaction score

- 4,611

- Points

- 113

So in conclusion, you may or may not need to add acid.

The search feature works but is tricky and difficult to use.

The people on here will assist you and lure you into our community.

You can add acid or not and still make good beer.

How's that for perfectly muddy?

Cheers,

Brian

The search feature works but is tricky and difficult to use.

The people on here will assist you and lure you into our community.

You can add acid or not and still make good beer.

How's that for perfectly muddy?

Cheers,

Brian

Last edited:

- Joined

- Mar 14, 2018

- Messages

- 11,133

- Reaction score

- 20,884

- Points

- 113

That is the beauty of this hobby!

You can get a sciencey as you want, or don't want with it.

For me, I like to get pretty sciencey about it, I like the continuous learning aspect of it.

You can get a sciencey as you want, or don't want with it.

For me, I like to get pretty sciencey about it, I like the continuous learning aspect of it.

I thank all of you for putting my mind at rest on this topic. I still don’t like having to do water calculations! And I dang sure am no chemist. Recently I have had trouble hitting my OG consistently and had settled on the idea that I’m not getting to the pH I need in the mash. I have a fairly expensive pH meter, but it needs recalibration, and I have a hard time trusting it after the first use post calibration. I do have some acidulated malt I use in light beers (2% of the grain bill according to the info I have). Despite all my troubles I do get good beer at the end, well, with the exception of the last beer (Zythos SMaSH experiment). Again, I appreciate everyone’s input on this. I think I’m just not going to worry about pH, and just let the grain and water do it’s thing.

- Joined

- Mar 31, 2021

- Messages

- 4,321

- Reaction score

- 6,416

- Points

- 113

ph plays a part in mash extraction, but crush, time and temp are the major players in that dept.I thank all of you for putting my mind at rest on this topic. I still don’t like having to do water calculations! And I dang sure am no chemist. Recently I have had trouble hitting my OG consistently and had settled on the idea that I’m not getting to the pH I need in the mash. I have a fairly expensive pH meter, but it needs recalibration, and I have a hard time trusting it after the first use post calibration. I do have some acidulated malt I use in light beers (2% of the grain bill according to the info I have). Despite all my troubles I do get good beer at the end, well, with the exception of the last beer (Zythos SMaSH experiment). Again, I appreciate everyone’s input on this. I think I’m just not going to worry about pH, and just let the grain and water do it’s thing.

if you dont have your own mill then you cant really do much with that, but adjusting your temp and checking you mash to be sure it is done is a great way to get closer to those SG marks.

go to any pharmacy and buy a tincture of iodine. when you are mashing take 1 drop of mash liquid and 1 drop of iodine on a white surface (paper plates work great) if there are unconverted starches in the wort, the iodine will turn black in a few seconds. if it stays yellowish, then your mash is done.

- Joined

- Mar 24, 2018

- Messages

- 3,099

- Reaction score

- 5,929

- Points

- 113

Yeah..no stupid questions here...and no stupid trolls looking to exhibit their stupidity!

If I could dig a little deeper @MrStacy , what has you using RO or Distilled over your tap water and do you have a style that you most often brew? You may be surprised that your local water just happens to mesh well with that style of beer. I like darker beers like porters and stouts...always have and when I started brewing and looking into water, aka the final frontier for home brewers, I discovered my well water and its mineral content was a fitting match to my fav beer style.

If I could dig a little deeper @MrStacy , what has you using RO or Distilled over your tap water and do you have a style that you most often brew? You may be surprised that your local water just happens to mesh well with that style of beer. I like darker beers like porters and stouts...always have and when I started brewing and looking into water, aka the final frontier for home brewers, I discovered my well water and its mineral content was a fitting match to my fav beer style.

Minbari- yeah, I’ve seen the iodine test. Honestly, I always mash a minimum of 1hour, and lately have been doing 90 minute mashes after reading a thread on extended mash times. I may eventually pick up some iodine and try it.

As to using RO and distilled water… I use it because my water I think has high amounts of chloramines which imparts a “bubble gum and dry white wine” flavor (some beers had a Juicy Fruit gum flavor). Sure, I’ve got campden tablets and I know I can boil my water first, but when I first started brewing several years ago I had so many beers I was disappointed in because of this strange flavor. A brew day is long enough without it becoming a two day ordeal with pre-boiling water, using extra propane, etc. Anyway, what I do know about my water profile is that it is great for dark beers based on the TA. I just found that using distilled and RO water produced clean tasting beer.

As to using RO and distilled water… I use it because my water I think has high amounts of chloramines which imparts a “bubble gum and dry white wine” flavor (some beers had a Juicy Fruit gum flavor). Sure, I’ve got campden tablets and I know I can boil my water first, but when I first started brewing several years ago I had so many beers I was disappointed in because of this strange flavor. A brew day is long enough without it becoming a two day ordeal with pre-boiling water, using extra propane, etc. Anyway, what I do know about my water profile is that it is great for dark beers based on the TA. I just found that using distilled and RO water produced clean tasting beer.

- Joined

- Mar 31, 2021

- Messages

- 4,321

- Reaction score

- 6,416

- Points

- 113

Minbari- yeah, I’ve seen the iodine test. Honestly, I always mash a minimum of 1hour, and lately have been doing 90 minute mashes after reading a thread on extended mash times. I may eventually pick up some iodine and try it.

As to using RO and distilled water… I use it because my water I think has high amounts of chloramines which imparts a “bubble gum and dry white wine” flavor (some beers had a Juicy Fruit gum flavor). Sure, I’ve got campden tablets and I know I can boil my water first, but when I first started brewing several years ago I had so many beers I was disappointed in because of this strange flavor. A brew day is long enough without it becoming a two day ordeal with pre-boiling water, using extra propane, etc. Anyway, what I do know about my water profile is that it is great for dark beers based on the TA. I just found that using distilled and RO water produced clean tasting beer.

boiling will not remove chlormines, camden tablets are the way to go, and they work nearly instantly

Ward, I don’t have a set particular style as of yet. I have settled on a cream ale recipe that I have brewed 3times so far as I really like it and know I will be doing a couple more batches this spring and summer. What I am focused on is learning to achieve consistent results in a few classic styles such as a kolsch, brown ale, dark German ales, amber ale, Scottish ale, and a good APA. Once I feel I have a good handle on a style of beer, then I want to branch out to tailoring a recipe to what I would want for me. I accidentally ended up with a doppelbock kit, not realizing it was a lager (don’t order recipe kits at night after having a few good craft beers). I have no way of lagering, Fortunately, the week I brewed it was quite chilly here during the day and near freezing at night. So, I kept the fermenter in the back bedroom, with the heating/cooling vent closed and the window open at night. The room stayed around 59F most of the first week. The lager yeast I used was saflager. After that week, I kegged it and put it in the fridge at 38F for another week, releasing any pressure build up every couple of days. Once there was no pressure releasing, I checked FG and it was right where it was supposed to be so I put the carbonation to it. That has been one of the best beers I have ever brewed and I can’t keep the wife out of it! It’s almost gone now!

- Joined

- Mar 14, 2018

- Messages

- 11,133

- Reaction score

- 20,884

- Points

- 113

My municipal water has chloromine in it, which is why I switched to RO a few years ago. What I like about using RO water is that I can adjust the profile to suit any style of beer I may wish to brew. It really isn't complicated at all. The various water additions are basically just ingredients in a recipe. It is no different than adding different seasonings for different results in cooking food.