- Joined

- Nov 20, 2012

- Messages

- 8,933

- Reaction score

- 7,194

- Points

- 113

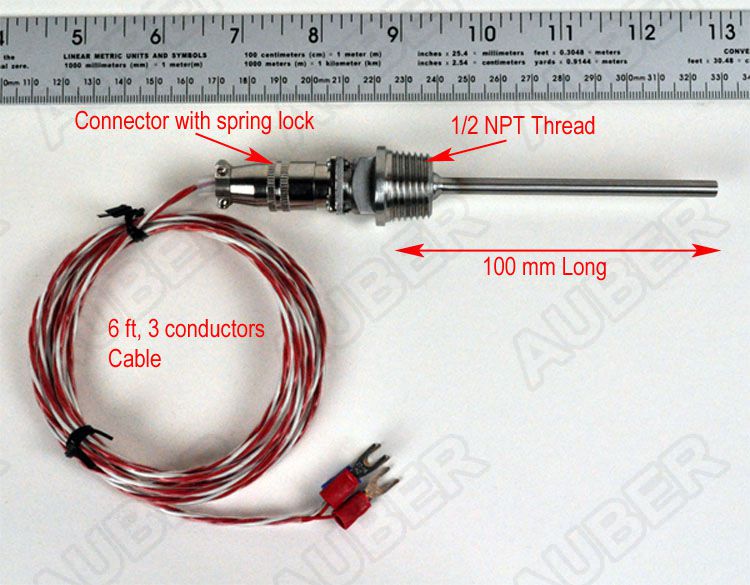

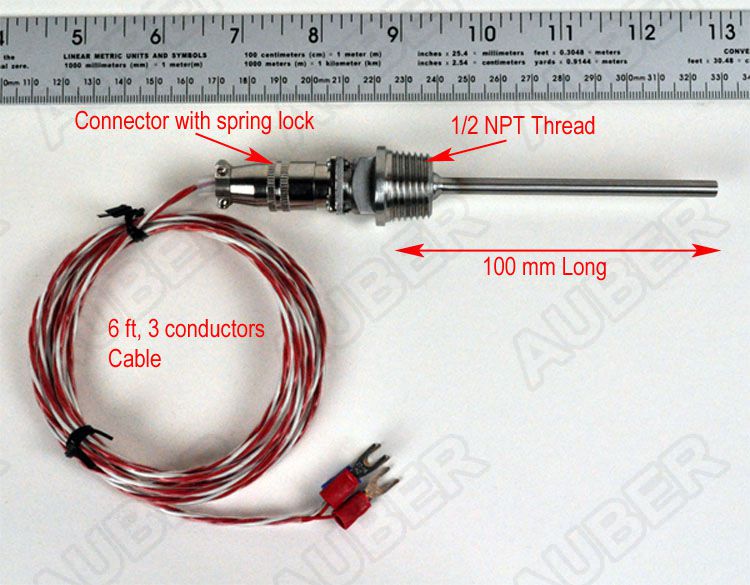

I use my internal gages not bragging but I am lol . I have 4 of these one in each pot and one portable

Specifications:

Accuracy Class A. +/-0.15 ºC at 0.0 ºC

Alpha 0.00385

Maximum temperature 300 ºC

Specifications:

Accuracy Class A. +/-0.15 ºC at 0.0 ºC

Alpha 0.00385

Maximum temperature 300 ºC