I was going to run 2 120 volt 1500 watt elements that way I didn't have to run a new circuits but I can always run a 240 circuit I'm only 60 feet away total that includes putting an underground coming back up through the wall Etc

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electric element protection

- Thread starter CRUNK

- Start date

- Joined

- Nov 20, 2012

- Messages

- 8,933

- Reaction score

- 7,196

- Points

- 113

2 -1500 watt elements might work better than a 2000, I've never tried it, I have one their only 4 inches long but their not ulwd so they don't last

- Joined

- Nov 20, 2012

- Messages

- 8,933

- Reaction score

- 7,196

- Points

- 113

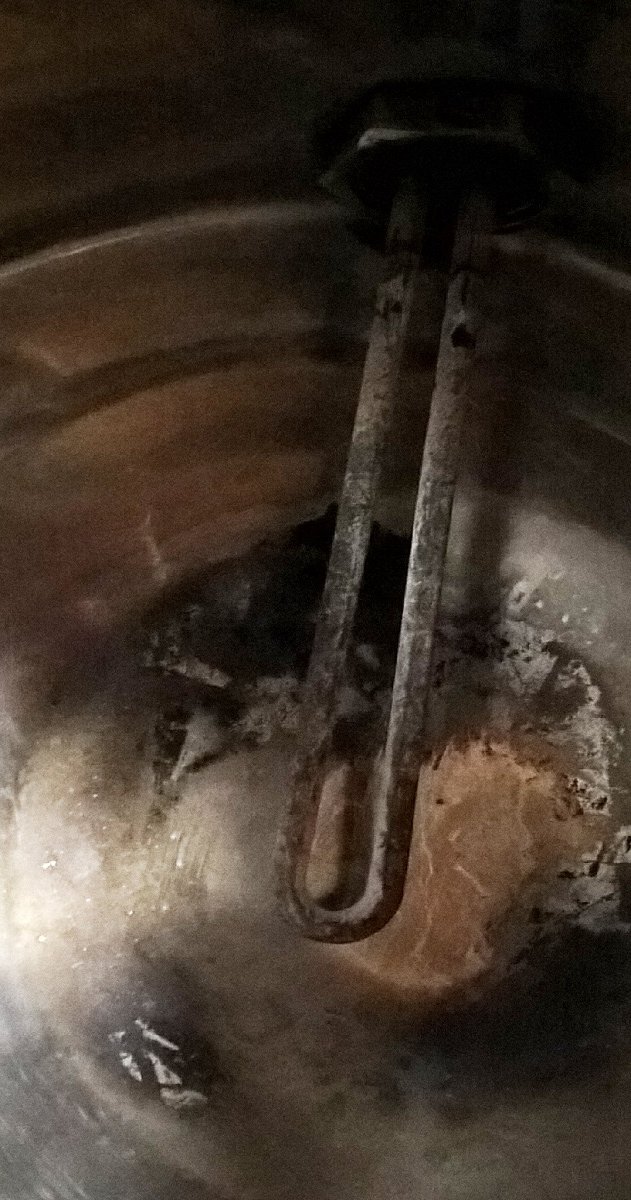

this is a 2000w element cleaned very well and you can see what happens with no coating

Im planning on stainless elements i know they still get dirty but i really want to move forward to electric brewing.

- Joined

- Feb 2, 2015

- Messages

- 1,867

- Reaction score

- 3,072

- Points

- 113

If I understand your question, you are asking if you can run more than 1 heater element on one controller. Yes you can, you can control multiple elements on separate AC circuits. Your PID needs to drive either a single SSR that can handle the current (50 amp) for 2 elements on a single circuit or multiple SSR's (25 amp) to control elements on separate circuits. That being said, it would be better to get a higher voltage (240 Vac) out to the shed, the higher the voltage the lighter the gauge of the wire without dropping power output.You very well be just the man I need to speak with I was going to use the blichmann boilcoil in my Brew Kettle I was going to have it shipped to stout tanks to put it in for me they asked if I would be interested in going with 21.5 TC ports and running do element which doesn't bother me except for the fact that I only have a 30 amp 120 circuit running to the shed which isn't bad because I can put a 40 amp breaker on that line and put 2:20 amp Breakers in the sub panel but now I need to know whether I can run two 1500 watt elements off of one PID or can I hook them up tie them into one single sensor in the same pot and run them both simultaneously through One controller and one piece of software so they act as one not 2

30 amp, 120Vac circuit can drive two 1500 watt but the current would be 25 amps. It will work, but NEC code says that a circuit should not have a continuous load that exceeds 80% of breaker capacity. That would be 24 amps. But....... it will work. 3000 watts is the bare minimum for a 5 gallon system.

On my RIMS system I used all stainless steel hot water heating elements with a tri-clamp adapter and I think they are superior to Blichmann's elements and they are cheaper.

- Joined

- Nov 20, 2012

- Messages

- 8,933

- Reaction score

- 7,196

- Points

- 113

this is a thought, 2 of these and its already built for tri clamp, a bit pricey but he has a twist lock disconnect, he also has some without the twist lock ends but currently out of stock

https://www.brewhardware.com/product_p/element1650_tc.htm

https://www.brewhardware.com/product_p/element1650.htm

https://www.brewhardware.com/product_p/element1650_tc.htm

https://www.brewhardware.com/product_p/element1650.htm

- Joined

- Feb 2, 2015

- Messages

- 1,867

- Reaction score

- 3,072

- Points

- 113

I use these and they are really nice.

https://www.brewershardware.com/TC15F10NPSCOV.html?category_id=287

If you use a 208 volt/5500 watt element at 120 volt, it works out to 1800 watts. That's the max current that should run through a 20 amp breaker and has a large surface area to avoid scorching.

https://www.highgravitybrew.com/store/pc/Heating-Element-5500-Watt-SS-14-inch-208V-423p9768.htm

https://www.brewershardware.com/TC15F10NPSCOV.html?category_id=287

If you use a 208 volt/5500 watt element at 120 volt, it works out to 1800 watts. That's the max current that should run through a 20 amp breaker and has a large surface area to avoid scorching.

https://www.highgravitybrew.com/store/pc/Heating-Element-5500-Watt-SS-14-inch-208V-423p9768.htm

- Joined

- Nov 20, 2012

- Messages

- 8,933

- Reaction score

- 7,196

- Points

- 113

So many options, but i think by the sounds of it, i should run a 240 circuit.

- Joined

- Nov 20, 2012

- Messages

- 8,933

- Reaction score

- 7,196

- Points

- 113

I agree, I looked but couldn't find anything lower than a 4500 in the better elements, a 3500 will work and that cuts down on the amperage to the shed so you wouldn't need a 30 amp main a 25 amp double pole would work

I agree, I looked but couldn't find anything lower than a 4500 in the better elements, a 3500 will work and that cuts down on the amperage to the shed so you wouldn't need a 30 amp main a 25 amp double pole would work

If im going to run a second circuit i might as well go with a 30 amp and just use a single 5500w element

Here is a cocktail napkin drawing for your amusement. It's set up just like my system is right now only I'm switching from gas-fired to Electric and I would love to go Arduino so I have the ability to add on later with mechanical valves that's also something that I'm probably going to have a lot of questions on.

My kettle doesn't have any , all the brains running my lil brewhouse are stuck in my head

I'm not smarter than my control panel unfortunately, and I always think I'll remember, but................

So I have simple float valves. I don't think I've "needed" it in the last 7 or 8 years, but it definitely is great to have in case of distractions/kids/dogs/phones/ during a brewday.

I put this system together based on the blichmann breweasy which is basically a two vessel Brew in the bag

Currently on this setup using a burner and a mash tun made from a cooler I am able to perform a step Mash and I am running less than half a degree difference between the two kettles so keeping the temperature where I want it has been awesome

- Joined

- Nov 20, 2012

- Messages

- 8,933

- Reaction score

- 7,196

- Points

- 113

you better get your kettle diameter before you add 5500w

So many options, but i think by the sounds of it, i should run a 240 circuit.

Well, if your batch size is going to be (and stay) very small, you could get away with not doing it. But when I had a heating element in my first brewery that ran on 110, it took 90 minutes to go from simmering to a boil. That just wouldn't do, and I did small batches then. I've never been sorry I went with a 240, utilizing a spa panel (cheaper way to do it) so that I had ample power, safe loads, and GFCI. Yes, it costs a little more, but spend once, cry once.

you better get your kettle diameter before you add 5500w

I will know all the dimensions on the kettles before I purchase any of the parts

Well, if your batch size is going to be (and stay) very small, you could get away with not doing it. But when I had a heating element in my first brewery that ran on 110, it took 90 minutes to go from simmering to a boil. That just wouldn't do, and I did small batches then. I've never been sorry I went with a 240, utilizing a spa panel (cheaper way to do it) so that I had ample power, safe loads, and GFCI. Yes, it costs a little more, but spend once, cry once.

I totally agree it's only going to cost me maybe a hundred bucks to run a 30 amp 240 vac service out to the shed

These kettles are going to be the basic kettles offered by Stout but the lids are going to be customized to accommodate low oxygen Brewing as they will have seals and I will be able to clamp the lids down onto the kettles

Everything is going to be tied together for closed transfers

Everything is going to be tied together for closed transfers