- Joined

- Mar 31, 2021

- Messages

- 3,218

- Reaction score

- 5,111

- Points

- 113

I made this quite a while ago to press the grains after my BIAB mash is finished. Gets the last bit of sugery goodness out with out burning myself.

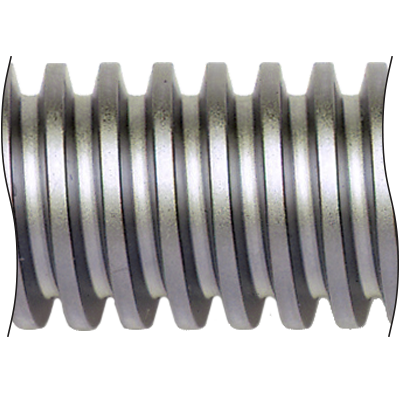

This is why you don't use zinc coated steel. Completely stripped out.

Replaced with a grade 8 5/8"-11 hardened steel bolt.

This is why you don't use zinc coated steel. Completely stripped out.

Replaced with a grade 8 5/8"-11 hardened steel bolt.

Last edited: