Hello all - I had a hell of a brew day yesterday! I kept my cool and my wits about me so I certainly made beer! However, I am looking for some advise for what to do next time I try and brew this one!

https://www.brewersfriend.com/homebrew/recipe/view/1456839/shuttz-bock-10g

I adjusted my grist to Liquor ratio down from my typical 1.5 to 1.25 since I had 30 lbs of grain! Despite that, I still had a hell of a time with the mash as my malt pipe just wasn't long enough for all the displaced liquor when adding the grains. (SEE PICS) - I made it through with some ingenuity but I certainly want to avoid this for next time... My question is how?

Should I:

1. Adjust my ratio to 1:1? - This would be an awefully thick mash and my efficiency would surely suffer ( It already did at 1.25 and all the issues - 70% instead of 75%)

2. Consider mashing a portion in a separate pot and conducting a decoction or two? - It would fit the recipe and as long as my day was yesterday I felt like I should have performed a triple decoction!

My only worry on 2 is in returning the decoction to the mash - it would still be unwieldy... (I think)

3. Just adjust my recipe to include some light DME?

- OR - if you've got any other ideas I am not thinking of! LOL - I would really appreciate the feedback.

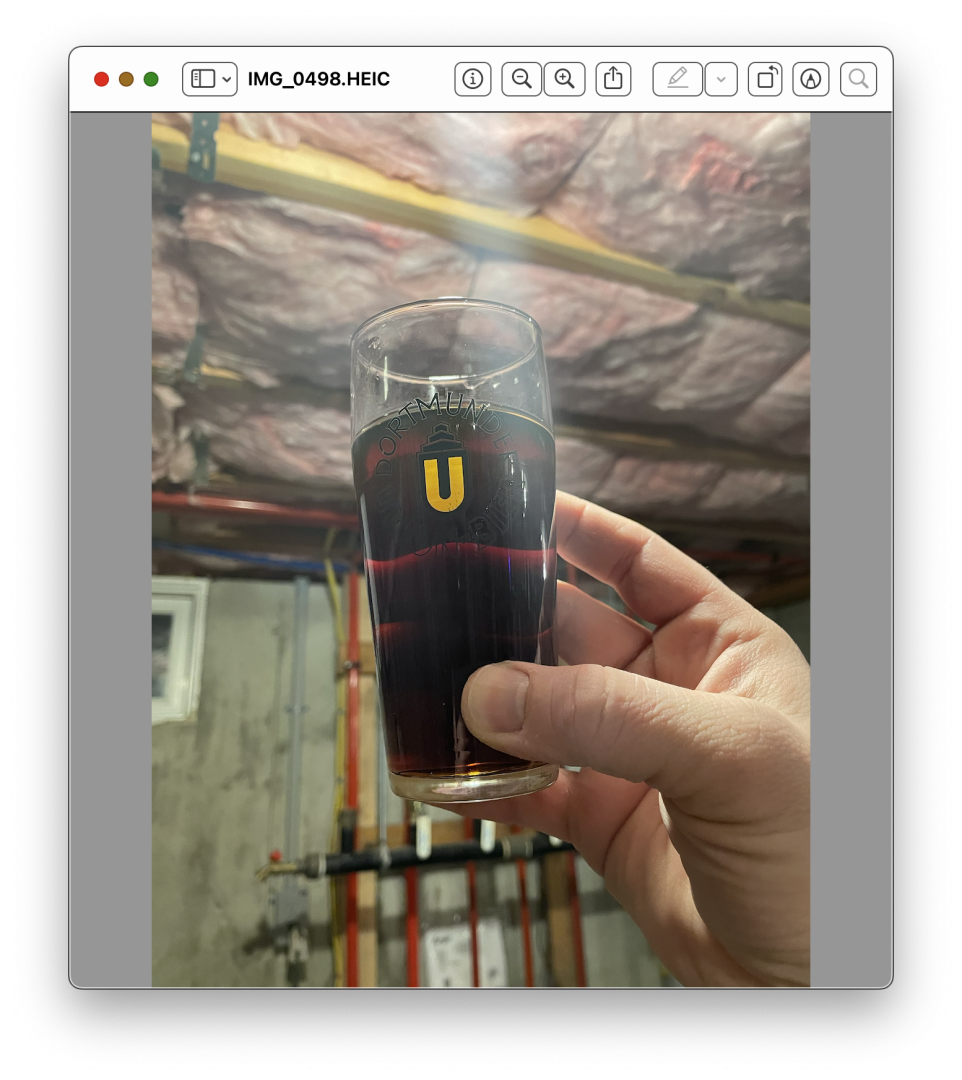

As you can see here - it made some wonderfully clear beer but instead of 1.071 I got 1.066 - this is a post boil shot of my sample for gravity reading...

https://www.brewersfriend.com/homebrew/recipe/view/1456839/shuttz-bock-10g

I adjusted my grist to Liquor ratio down from my typical 1.5 to 1.25 since I had 30 lbs of grain! Despite that, I still had a hell of a time with the mash as my malt pipe just wasn't long enough for all the displaced liquor when adding the grains. (SEE PICS) - I made it through with some ingenuity but I certainly want to avoid this for next time... My question is how?

Should I:

1. Adjust my ratio to 1:1? - This would be an awefully thick mash and my efficiency would surely suffer ( It already did at 1.25 and all the issues - 70% instead of 75%)

2. Consider mashing a portion in a separate pot and conducting a decoction or two? - It would fit the recipe and as long as my day was yesterday I felt like I should have performed a triple decoction!

My only worry on 2 is in returning the decoction to the mash - it would still be unwieldy... (I think)

3. Just adjust my recipe to include some light DME?

- OR - if you've got any other ideas I am not thinking of! LOL - I would really appreciate the feedback.

As you can see here - it made some wonderfully clear beer but instead of 1.071 I got 1.066 - this is a post boil shot of my sample for gravity reading...