- Joined

- Jul 23, 2013

- Messages

- 70

- Reaction score

- 1

- Points

- 0

After writing this, I've come to the conclusion that the subject is probably widely known already as a technique, but since it was new to me, there's probably someone else out there that will find it new as well.

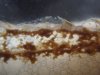

Just uncovered the carboy to find the situation in the attached photo.

A few things; the frozen baseball-puck cold pack has been there since about 3pm, and I took the picture at 6:30pm. Before I put the cold pack in the carboy handle, for the simple reason that it would fit there, the foam in the carboy was lower, and uniform in color.

After this and some other cold packs strewn below, a trash bag went over the frozen pack and carboy, then a foil-covered cardboard box went over, for darkness and to control heat accumulation in the carboy, and in the brew bucket beside it. Despite these attempts the carboy went from a morning temp of about 68F to about 70 in the picture, as the outside ambient temp had climbed to the mid-80's over the course of several hours. Still an acceptable temp was maintained, I'll get fresh ice packs in first thing tomorrow am and should be able to maintain cooler temps from that point forward.

Did the presence of the cold pack, nullify the foam, creating a flow in the foam, and the toasted marshmallow colored foam on the right edge? It is not bad stuff. I think it is a sediment buildup due to condensate effects on the other side of the foam column, where the ice pack is. Could be residual sanitizer that ran off of the glass due to the condensate, as well, it seems a similar color, though darker.

So, did the cold pack in containment at that location, actually retard foam development in the head space of this carboy? I'm thinking it did, and might even have prevented a blowover. Maybe not, I don't know!

More experimentation is necessary to be sure, but focused cooler temperature, and resultant condensation, seems to affect the surface tension characteristics of the foam and of the glass that contacts the foam, at the head space of the carboy.

Plus, cold packs are just plain cool :lol: thanks for any thoughts - John

Just uncovered the carboy to find the situation in the attached photo.

A few things; the frozen baseball-puck cold pack has been there since about 3pm, and I took the picture at 6:30pm. Before I put the cold pack in the carboy handle, for the simple reason that it would fit there, the foam in the carboy was lower, and uniform in color.

After this and some other cold packs strewn below, a trash bag went over the frozen pack and carboy, then a foil-covered cardboard box went over, for darkness and to control heat accumulation in the carboy, and in the brew bucket beside it. Despite these attempts the carboy went from a morning temp of about 68F to about 70 in the picture, as the outside ambient temp had climbed to the mid-80's over the course of several hours. Still an acceptable temp was maintained, I'll get fresh ice packs in first thing tomorrow am and should be able to maintain cooler temps from that point forward.

Did the presence of the cold pack, nullify the foam, creating a flow in the foam, and the toasted marshmallow colored foam on the right edge? It is not bad stuff. I think it is a sediment buildup due to condensate effects on the other side of the foam column, where the ice pack is. Could be residual sanitizer that ran off of the glass due to the condensate, as well, it seems a similar color, though darker.

So, did the cold pack in containment at that location, actually retard foam development in the head space of this carboy? I'm thinking it did, and might even have prevented a blowover. Maybe not, I don't know!

More experimentation is necessary to be sure, but focused cooler temperature, and resultant condensation, seems to affect the surface tension characteristics of the foam and of the glass that contacts the foam, at the head space of the carboy.

Plus, cold packs are just plain cool :lol: thanks for any thoughts - John