Gday all.

Grabbed another PID controller to use in my brewery.

Wired her in yesterday eve along with the PT 100 probe yay all working in good order.

Now I just have some questions about Tuning .

.

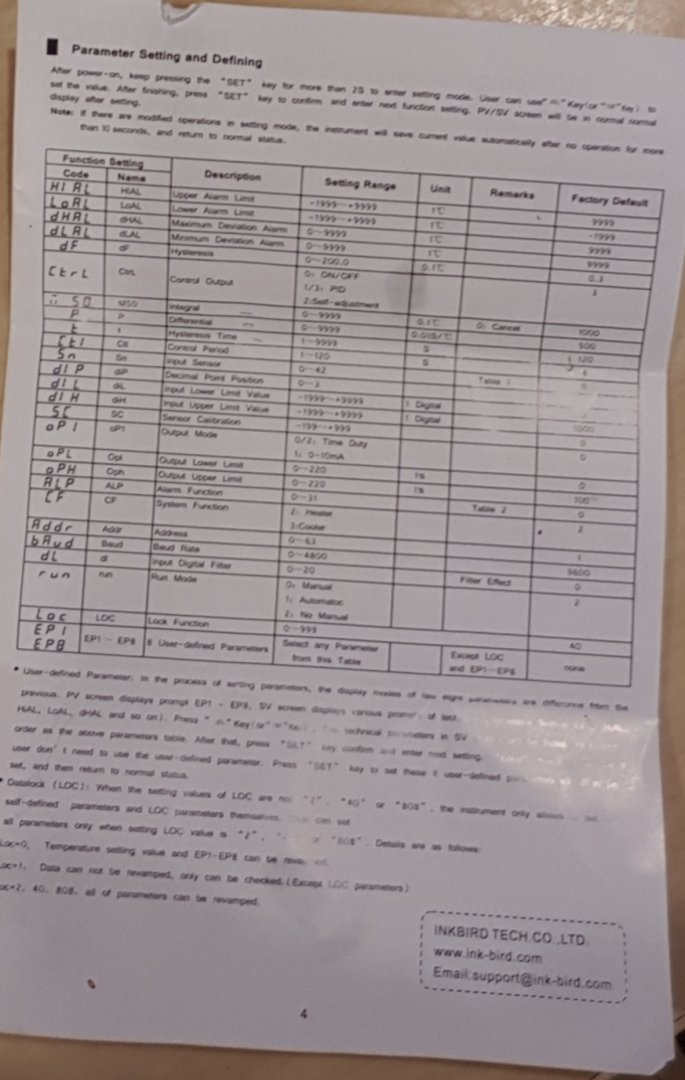

In the Settings I can't find exactly what the PID inputs are see .

Ok that not a good photo but M50 it's got is Integral cool that's helpful.

But P it has as Differential?

Now what is Hysteresis Time

I did a quick bit of research on what this is it seems slightly different to PID control but it used to control to a set value but not as precisely as a PID

Anyhow I'll run the Auto Tune on kettle and see where this gets me.

Knowing me thought I want to know what altering these set points o in correlation to the Set point.

So far having had a little play last night I noticed the Lower the D (differential not Derivative) the slower to set point the higher the quicker.

Anyhow if anyone has any experience with these INKBIRD pids or what the go with Hysteresis time is I'd gladly appreciate it.

Grabbed another PID controller to use in my brewery.

Wired her in yesterday eve along with the PT 100 probe yay all working in good order.

Now I just have some questions about Tuning

In the Settings I can't find exactly what the PID inputs are see .

Ok that not a good photo but M50 it's got is Integral cool that's helpful.

But P it has as Differential?

Now what is Hysteresis Time

I did a quick bit of research on what this is it seems slightly different to PID control but it used to control to a set value but not as precisely as a PID

Anyhow I'll run the Auto Tune on kettle and see where this gets me.

Knowing me thought I want to know what altering these set points o in correlation to the Set point.

So far having had a little play last night I noticed the Lower the D (differential not Derivative) the slower to set point the higher the quicker.

Anyhow if anyone has any experience with these INKBIRD pids or what the go with Hysteresis time is I'd gladly appreciate it.

Last edited: