- Joined

- Mar 14, 2018

- Messages

- 9,031

- Reaction score

- 16,389

- Points

- 113

I have been wet conditioning for a while now. The reasons I started doing this were trying to improve efficiency, and to improve flow through the mash (I have a 35L Brewzilla). You hear about people struggling with stuck mashes, or excruciatingly slow mashes with these machines, for me this made all of the difference in the world. The result from wet conditioning is that the husks being more pliable will tear, instead of being literally crushed. When it was first suggested to me, it seemed complicated, so I did some research before trying it myself. It turned it to be a super simple process. If you are interested, here is my process.

First I split the grains into two buckets, the reason for this is that it gets tough to stir if the grains are all in one bucket.

The say to use 2% of the weight of the grist to be milled in water. In reality I actually use a bit more than that personally.

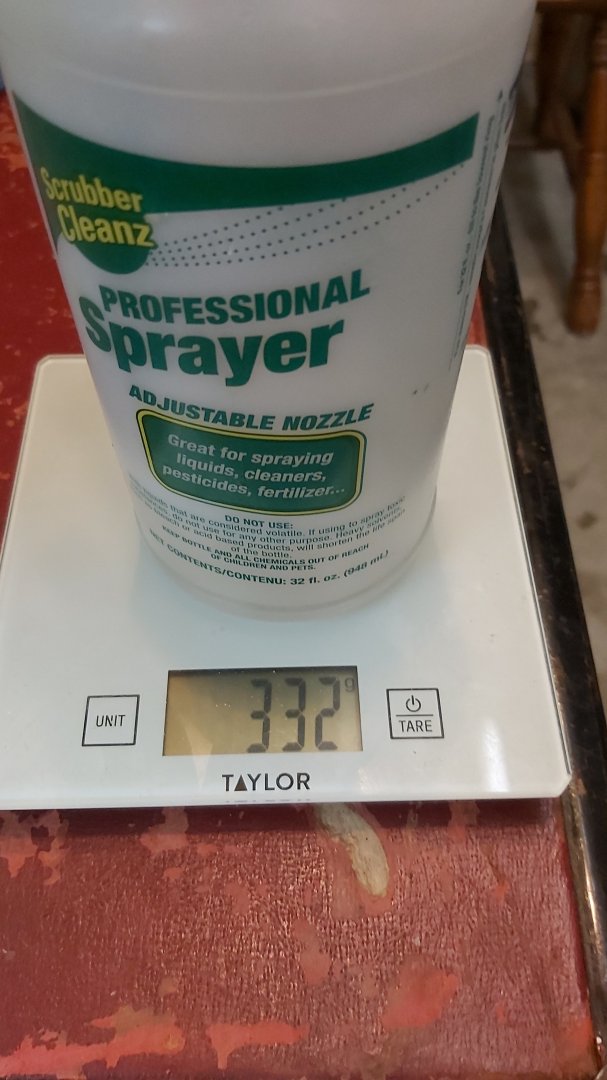

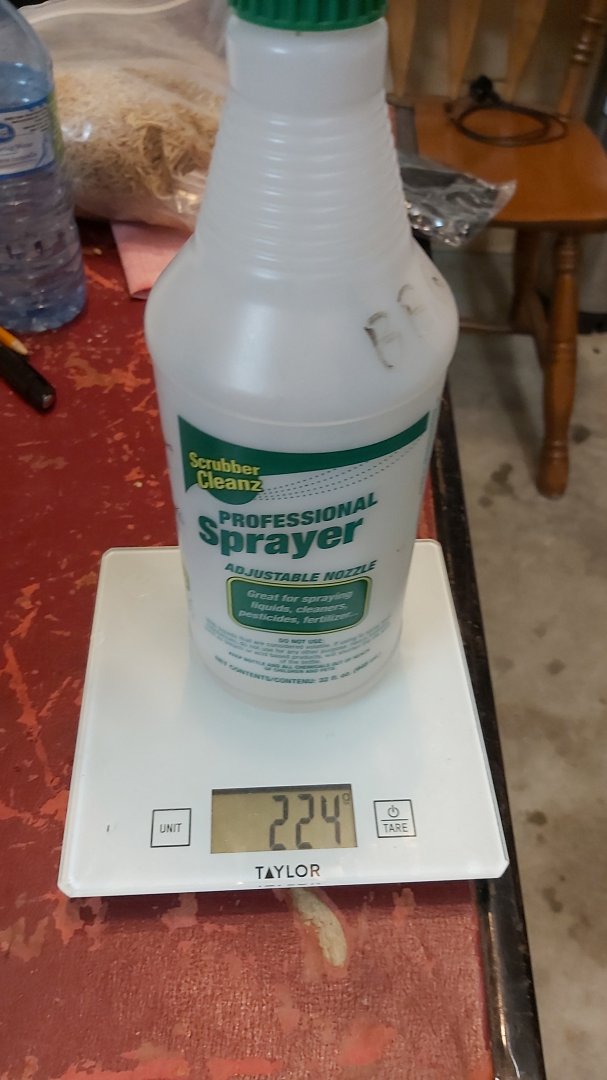

The easiest way to measure the amount of water is to weigh the spray bottle before starting, and placing it back on the scale as you go.

I spray some water, then stir it up good, and repeat until the grains have a bit of a leathery feel to them. I then repeat this with the second bucket. Once done I combine them back into one bucket.

Don't mill right away, you will gum up your rollers if you do. Let it sit for 20 to 30 minutes, give it another bit of a stir and mill.

Grains in two buckets

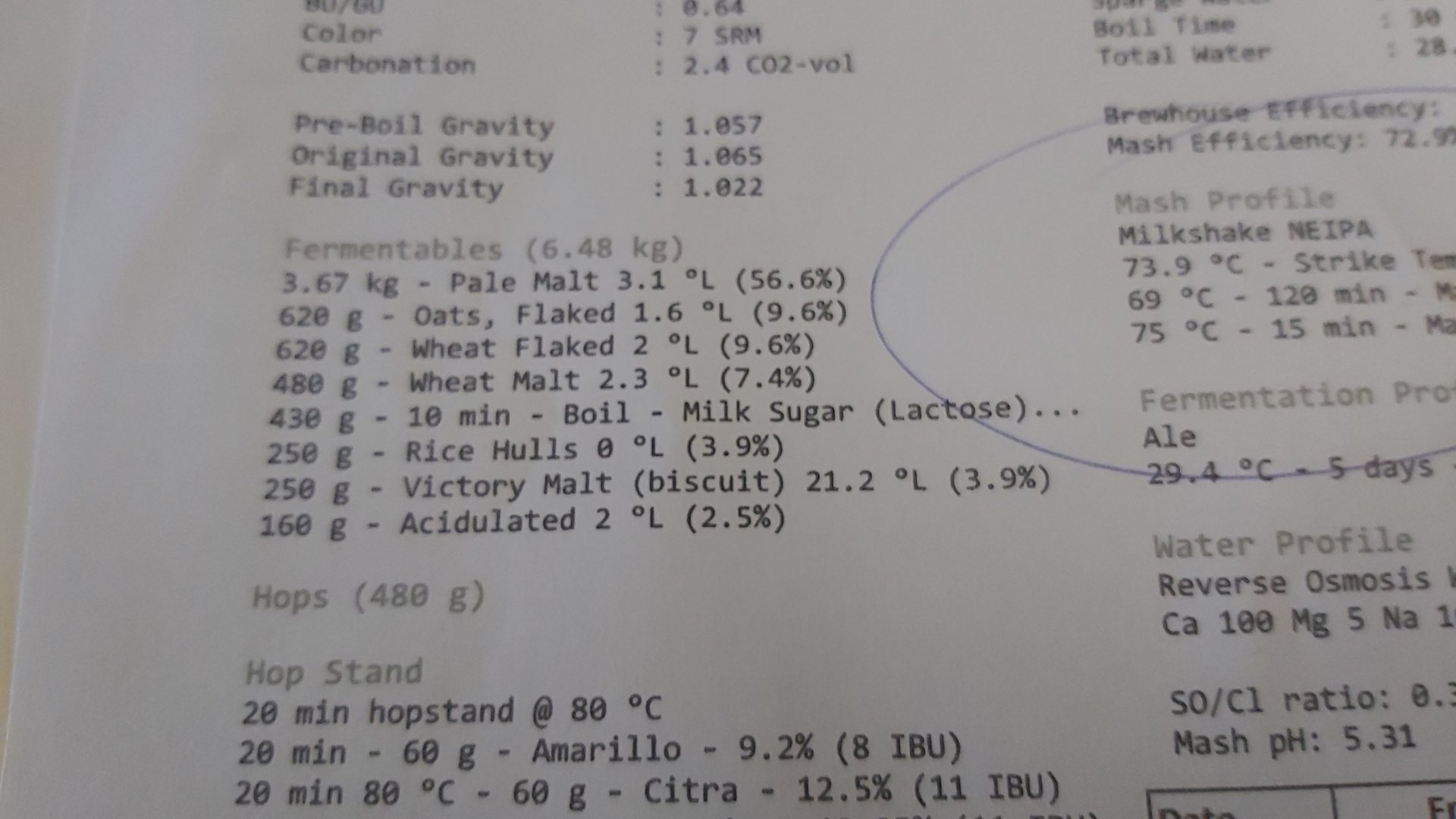

As I don't crush flaked, lactose, or rice hulls, I calculate the water based on what is going to be milled. I do still use rice hulls in a recipe like this with a lot of flaked. No need for rice hulls otherwise.

Next two pictures are self explanatory, I used a bit more than 2%

Non conditioned grains on the left, wet conditioned on the right.

Close ups

Hope this helps anyone who has slow or stuck mash, or sparge issues!

First I split the grains into two buckets, the reason for this is that it gets tough to stir if the grains are all in one bucket.

The say to use 2% of the weight of the grist to be milled in water. In reality I actually use a bit more than that personally.

The easiest way to measure the amount of water is to weigh the spray bottle before starting, and placing it back on the scale as you go.

I spray some water, then stir it up good, and repeat until the grains have a bit of a leathery feel to them. I then repeat this with the second bucket. Once done I combine them back into one bucket.

Don't mill right away, you will gum up your rollers if you do. Let it sit for 20 to 30 minutes, give it another bit of a stir and mill.

Grains in two buckets

As I don't crush flaked, lactose, or rice hulls, I calculate the water based on what is going to be milled. I do still use rice hulls in a recipe like this with a lot of flaked. No need for rice hulls otherwise.

Next two pictures are self explanatory, I used a bit more than 2%

Non conditioned grains on the left, wet conditioned on the right.

Close ups

Hope this helps anyone who has slow or stuck mash, or sparge issues!