My NEIPA has been on gas for a week now. The keg is dispensing the beer with 95% foam. The temperature of the kegerator is 34°f and the tower is fan cooled so temperature is the not the issue. The pressure was set for 14 psi and the dispensing hose is a standard 3/16 in ID beverage hose. Because I like to carbonate the beer on the higher side, I use a longer hose in this case it’s 10 feet. After several days of nothing but foam I decided to try a couple of different things. The first was to change the beverage line to a 15 foot hose. This did absolutely nothing proving that hose length was not the issue. The next thing I tried was to actually increase the keg pressure to 18 psi knowing that it would probably at best do nothing and in fact this was the case. I then decided to try one last experiment. I bled the head space to near nothing and decided to see if the higher pressure in solution would push the beer through the dispenser without foam. The beer for all practical purposes did not flow anecdotally verifying that it’s the head pressure that propels the beer not the CO2 in solution. In other words if the head pressure is near zero then no matter how carbonated the beer, it won’t dispense or at least it won’t dispense at a reasonable rate. However, I did learn that if the head pressure was reduced but not all the way, not only did it flow, albeit more slowly, but the foam was acceptable, perhaps only 10%. This is good news because now I know how to dispense a highly carbonated beer with minimal foam but the down side is I have to turn off the manifold pressure and partially bleed the head space while I pour and then turn it back on again between each pour. I would guess that many of you have solved this problem so I’m all ears.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nothing but foam from my kegerator

- Thread starter Markok

- Start date

I have a Keg King with 10’ lines. After a keg is carbed (whatever method) I run no more than 10 lbs. Usually about 8 lbs. Most low cost regulators are S#^t for pressure accuracy at lower levels. So give a quick purge on the PRV on the keg once in a while and adjust the regulator as necessary.

- Joined

- Jan 19, 2016

- Messages

- 3,878

- Reaction score

- 3,325

- Points

- 113

Depending on temperature, 14PSI is capable of over-carbing the beer. When it's over carbed, it'll want to foam no matter how slowly you push it out. Purge the head pressure, unhook from CO2 and let it sit overnight. Then without hooking back up to CO2, see if it will dispense. You'll probably find that enough CO2 has come out of suspension to add some head pressure and push the beer out. At that point you can judge whether it's over carbed, From there, just adjust the pressure so that it's lower for storage and higher for serving.

Good luck!

Good luck!

- Joined

- Oct 19, 2017

- Messages

- 1,815

- Reaction score

- 2,378

- Points

- 113

↑↑↑ What I do when I'm getting too much foam (3 metre/10 foot lines as well).

- Joined

- Nov 16, 2013

- Messages

- 3,107

- Reaction score

- 2,430

- Points

- 113

- Location

- Upper Michigan/S. Florida

It's overcarbed (14 psi at 34 degrees is 3.0 volumes) as stated, PLUS your lines are way too short to dispense that volume. For 2.4 volumes, generally you need 1' of 3/16" tubing for each psi on the regulator, so you'd need 14' at a minumim at 45 degrees. With the colder temperature and the higher carb level, you'd probably want 20' lines. You said you tried longer lines, proving that wasn't the issue- but it is. At least, it's a large part of the issue since the beer is so overcarbed.

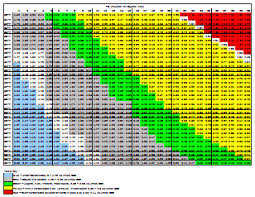

I dispense soda (30 psi at 40 degrees) with a 25' line but soda doesn't foam so I can get buy with a "short" line for it. This carb chart can help you pick the right psi for your temperature to get it right.

At this point, not much you can do except turn off the gas and vent it as often as possible until it equalizes at a much more manageable 9 psi.

I dispense soda (30 psi at 40 degrees) with a 25' line but soda doesn't foam so I can get buy with a "short" line for it. This carb chart can help you pick the right psi for your temperature to get it right.

At this point, not much you can do except turn off the gas and vent it as often as possible until it equalizes at a much more manageable 9 psi.

I thought it was my eyes but zooming all the way in didn't make it better.

I can't tell if the chart mentions Elevation. I live at 6,000 above sea level & that requires/suggests that I add 6 psi to the chart pressure to achieve the desired carb level.

I run 12psi to achieve 2.3 vols at 34 F.

Works for me.

I can't tell if the chart mentions Elevation. I live at 6,000 above sea level & that requires/suggests that I add 6 psi to the chart pressure to achieve the desired carb level.

I run 12psi to achieve 2.3 vols at 34 F.

Works for me.

By the way, I'd like a readable copy of this chart. Please.

- Joined

- Mar 14, 2018

- Messages

- 9,010

- Reaction score

- 16,363

- Points

- 113

The chart is in the calculators here

https://www.brewersfriend.com/force-carbonation-chart/

https://www.brewersfriend.com/force-carbonation-chart/

Thanks Craigerr. I have a b&w chart covering much less temp & psi ranges. I like having a copy of the chart taped to the kegerator.

- Joined

- Sep 5, 2015

- Messages

- 3,792

- Reaction score

- 7,373

- Points

- 113

Elevation for sure comes into play. At over 5000 above sea level, my reg is set just a hair over 14#.

- Joined

- Jul 16, 2012

- Messages

- 10,254

- Reaction score

- 8,363

- Points

- 113

I keep mine set at about 8-9 psi.Elevation for sure comes into play. At over 5000 above sea level, my reg is set just a hair over 14#.

In my extremely limited experience, trying to slow the pour with the picnic tap lever will cause awesome quantities of foam. Try this if not done already: Open it full bore and go down the side of the glass. I have dispensed at 15 PSI like this and got reasonable results.

I have mine set around 10psi I run 5meter lines with 4mm 3c so plent of line equalization happening I like a slow pour low carb.