Hey all,

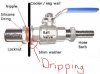

Had a frustrating start to the brew day which started out as a triple decoction Marzen for Oktoberfest, and turned into a single decoction cluster F*#$ of not being able to adequately seal my ball valves. No matter what I did, they leaked. I've got 2 Igloo 5 gallon.

The ball valves are pretty new; having used one once before, and the other, less than 5 times. No matter what I did, the seals would leak. After wasting an hour trying to fix the situation, I decided to start, and swapped one of the manual valves on my sparge water which was very annoying but at least it was sealed. Now the obvious thing to do is to replace all seals which I will do next shopping trip.

Any other recommendations?

Had a frustrating start to the brew day which started out as a triple decoction Marzen for Oktoberfest, and turned into a single decoction cluster F*#$ of not being able to adequately seal my ball valves. No matter what I did, they leaked. I've got 2 Igloo 5 gallon.

The ball valves are pretty new; having used one once before, and the other, less than 5 times. No matter what I did, the seals would leak. After wasting an hour trying to fix the situation, I decided to start, and swapped one of the manual valves on my sparge water which was very annoying but at least it was sealed. Now the obvious thing to do is to replace all seals which I will do next shopping trip.

Any other recommendations?