You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show your DIY Projects

- Thread starter DanC

- Start date

Debate debated

- Joined

- Mar 24, 2018

- Messages

- 2,704

- Reaction score

- 5,034

- Points

- 113

Nobody would appreciate the effort involved to do that. It's a tankless job...

(Sorry , couldn't resist)

Smart Plug....sounds re-volt-ing

- Joined

- Mar 12, 2017

- Messages

- 2,127

- Reaction score

- 4,510

- Points

- 113

Nothing strictly brewing related but I think I may have to build myself a brewery sign. Did a bunch of scroll work training this weekend and thought this looked particularly cool.

View attachment 14492

DIY and fire!!

- Joined

- Jul 27, 2017

- Messages

- 4,679

- Reaction score

- 4,524

- Points

- 113

It's a lot of fun. And helps me burn off the calories from this hobby.  I will say with absolute certainty that this forum is a much better learning environment than the smithing ones I found. I've decided I'll stick to books for that and the local smith who sells me supplies.

I will say with absolute certainty that this forum is a much better learning environment than the smithing ones I found. I've decided I'll stick to books for that and the local smith who sells me supplies.

- Joined

- Mar 12, 2017

- Messages

- 2,127

- Reaction score

- 4,510

- Points

- 113

They should put a "No Newbies" warning on the top of their forum. I'm so glad BF is as friendly and welcoming as it is (as long as we stay away from politics that is  ). Hopefully if I ever get to be that crabby old guy snapping at the newbies, someone will remind me I was once the newbie! If that doesn't work then give me my pills, sit me in my recliner and turn on Wheel of Fortune.

). Hopefully if I ever get to be that crabby old guy snapping at the newbies, someone will remind me I was once the newbie! If that doesn't work then give me my pills, sit me in my recliner and turn on Wheel of Fortune.

- Joined

- Jul 27, 2017

- Messages

- 4,679

- Reaction score

- 4,524

- Points

- 113

It's why I use this forum and don't really use any of the others.

It was especially frustrating being told I had to use X and only X when doing something cause everything else is garbage but you can't buy X in Canada. No interest in helping me compensate, just "Buy X or don't bother". Which is not cool.

It was especially frustrating being told I had to use X and only X when doing something cause everything else is garbage but you can't buy X in Canada. No interest in helping me compensate, just "Buy X or don't bother". Which is not cool.

- Joined

- Jul 19, 2019

- Messages

- 2,062

- Reaction score

- 5,050

- Points

- 113

"Hey you kids, get away from that keg!"

- Joined

- Mar 14, 2018

- Messages

- 8,995

- Reaction score

- 16,329

- Points

- 113

Another low tech, but slick, and time saving DIY.

Cleaning beer lines is such a little thing to do, but setting up to do it is a pain (for me at least).

Not anymore with this little fella!

I can now remove the beer line when a keg kicks, connect it to my laundry faucet and run super hot water through it right away!

Lines may need a proper cleaning sometimes, but running 160F (71C) water through these lines each time should keep them clean enough.

I will immerse in sanitizer before connecting to another keg.

Cleaning beer lines is such a little thing to do, but setting up to do it is a pain (for me at least).

Not anymore with this little fella!

I can now remove the beer line when a keg kicks, connect it to my laundry faucet and run super hot water through it right away!

Lines may need a proper cleaning sometimes, but running 160F (71C) water through these lines each time should keep them clean enough.

I will immerse in sanitizer before connecting to another keg.

- Joined

- Mar 14, 2018

- Messages

- 8,995

- Reaction score

- 16,329

- Points

- 113

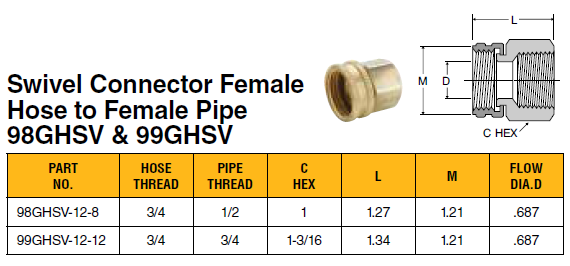

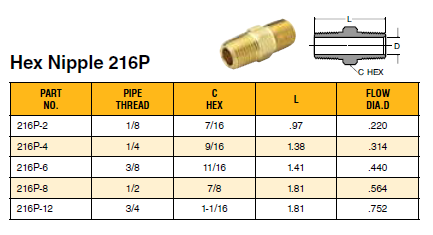

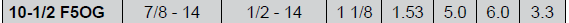

Fittings are as follows:

Parker PN: 98GHSV-12-8

Parker PN: 216P-8

Parker Hose Products Div PN: 0502-10-8

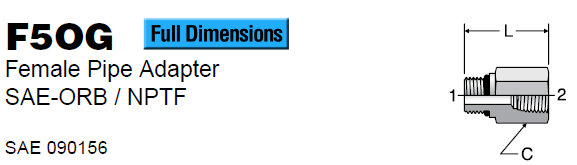

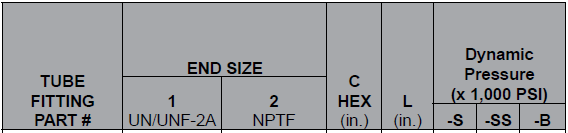

Parker Tube Fittings Div PN: 10-1/2 F5OG-S

Generic Manufacturer PN: 6405-10-08

The #10 SAE/ORB thread is 7/8-14, same as tap shank threads!

Just remove the oring pictured, and use the seal washer from your tap.

Parker PN: 98GHSV-12-8

Parker PN: 216P-8

Parker Hose Products Div PN: 0502-10-8

Parker Tube Fittings Div PN: 10-1/2 F5OG-S

Generic Manufacturer PN: 6405-10-08

The #10 SAE/ORB thread is 7/8-14, same as tap shank threads!

Just remove the oring pictured, and use the seal washer from your tap.

- Joined

- Nov 20, 2012

- Messages

- 8,604

- Reaction score

- 6,609

- Points

- 113

I have boxes of parts just like you described and the fitting that always breaks for me is a swivel connector, cant seem to find any worth the money

example of what breaks, these Chinese parts

https://www.amazon.com/HZFJ-Connector-Adapter-Fittings-Extension/dp/B08DNHVCVF

example of what breaks, these Chinese parts

https://www.amazon.com/HZFJ-Connector-Adapter-Fittings-Extension/dp/B08DNHVCVF

- Joined

- Mar 14, 2018

- Messages

- 8,995

- Reaction score

- 16,329

- Points

- 113

I have boxes of parts just like you described and the fitting that always breaks for me is a swivel connector, cant seem to find any worth the money

example of what breaks, these Chinese parts

https://www.amazon.com/HZFJ-Connector-Adapter-Fittings-Extension/dp/B08DNHVCVF

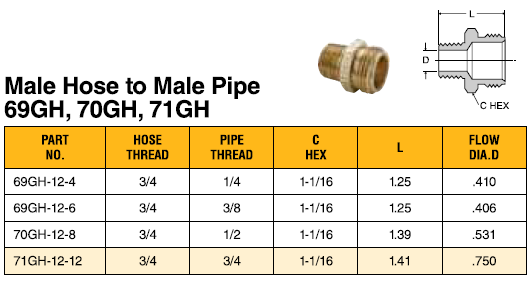

Parker does not have that size, in the GH Swivel x MNPT they only have 1/4" and 3/8" MNPT for some reason.

Fairview has this fitting though, part number 194-D. I never had any quality issues with Fairview Brass.

I have reached out to Fairview to see where you can buy their products in your area, will let you know when I hear back.

This is the business I am in, so I have access to anything hose and fitting wise at my place of work.

- Joined

- Mar 14, 2018

- Messages

- 8,995

- Reaction score

- 16,329

- Points

- 113

Having said all of that, I would switch those connections around, I would go with the more reliable male GH x MNPT, and put the GH swivel on the mating part.

Here is a link to the Parker Brass Fitting catalog from our website as well.

https://regionalhose.com/wp-content...ite_and_Thermoplastic_Fittings_and_Valves.pdf

These fittings are on page 308-310 (J22-J24)

Here is a link to the Parker Brass Fitting catalog from our website as well.

https://regionalhose.com/wp-content...ite_and_Thermoplastic_Fittings_and_Valves.pdf

These fittings are on page 308-310 (J22-J24)

- Joined

- Sep 5, 2015

- Messages

- 3,792

- Reaction score

- 7,373

- Points

- 113

This minus the black piece is what I use to clean all my lines.

https://www.homebrewing.org/The-Grainfather-Tap-Adapter-Set_p_7577.html

https://www.homebrewing.org/The-Grainfather-Tap-Adapter-Set_p_7577.html

- Joined

- May 10, 2019

- Messages

- 1,153

- Reaction score

- 2,633

- Points

- 113

Spring MUST be just around the corner!

Last fall I stashed a few hops plant I had started in pots in the garage. I keep it about 48*f as I go out and work in it quite a bit and have things I don't want frozen.

Anyway, I just noticed the plants are getting enough sunlight that they are coming alive!

Last edited:

Mine are still quite frozen

- Joined

- Mar 23, 2018

- Messages

- 1,116

- Reaction score

- 2,170

- Points

- 113

I can only really brew with the garage door open due to the rain that would fall inside the garage and soak everything because of the steam from the boil. Well that is until now - I hope.

I fitted a 45cm high frame at ground level between the garage door sides and installed a turbo (manufacturers description) in-line fan at one end. The fan is connected to a plastic bell-end (no not me!) that is suspended over the kettle using the coiled plastic ducting.

The bell is supported above the kettle top with spacers to allow air to be sucked in and, hopefully, carry the steam away down the ducting by the fan. The frame at the door allows me to shut the garage door down to the same level and stop any howling wind that I usually get battering the garage doorway - especially when I want to brew when the weather is crap.

Well that is the plan anyway. Test runs suggest it does work but because the bell is so thin there may be more condensation created than the fan can carry away. I could reduce the ducting length and insulate the bell to avoid that... I'll wait and see...

I fitted a 45cm high frame at ground level between the garage door sides and installed a turbo (manufacturers description) in-line fan at one end. The fan is connected to a plastic bell-end (no not me!) that is suspended over the kettle using the coiled plastic ducting.

The bell is supported above the kettle top with spacers to allow air to be sucked in and, hopefully, carry the steam away down the ducting by the fan. The frame at the door allows me to shut the garage door down to the same level and stop any howling wind that I usually get battering the garage doorway - especially when I want to brew when the weather is crap.

Well that is the plan anyway. Test runs suggest it does work but because the bell is so thin there may be more condensation created than the fan can carry away. I could reduce the ducting length and insulate the bell to avoid that... I'll wait and see...